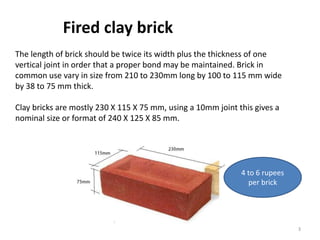

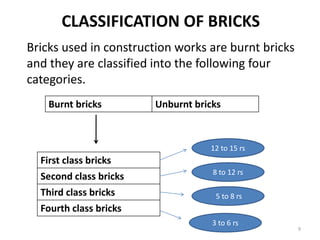

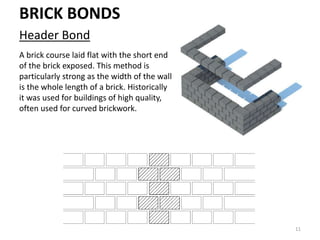

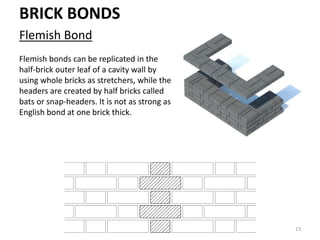

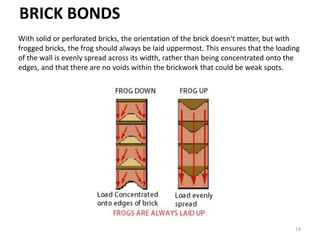

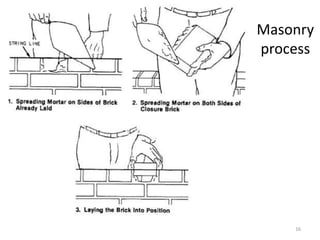

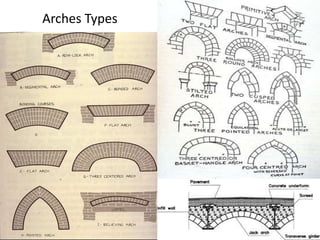

This document summarizes different types of bricks used in construction including clay, fly ash, and glass bricks. It discusses brick sizes, costs, classifications of burnt clay bricks from first to fourth class, and various bonding patterns used when laying bricks, including header, English, and Flemish bonds. It also lists common building elements constructed using bricks such as arches, foundations, columns, and facades.