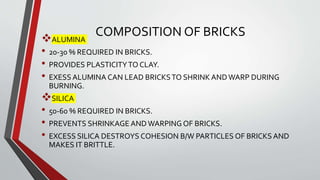

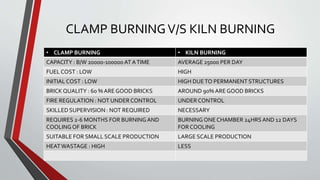

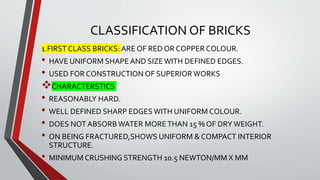

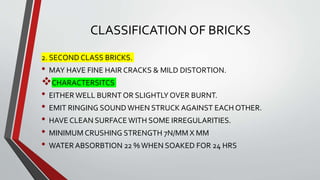

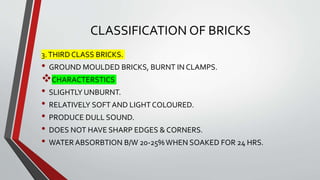

The document provides a comprehensive overview of bricks, covering their composition, manufacturing process, and classification. It details the differences between bricks and stones, as well as the size, weight, and color variations of bricks. Additionally, it categorizes bricks into unburnt and burnt types, along with specific classes of burnt bricks based on their quality and characteristics.