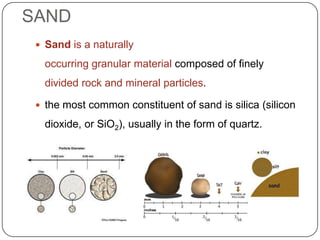

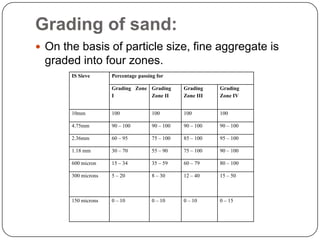

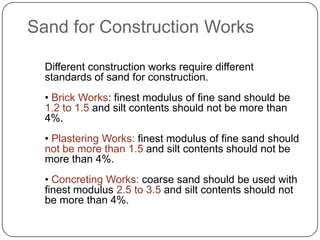

Sand is a naturally occurring granular material composed of finely divided rock and mineral particles, with silica being the most common constituent. There are different types of sand sourced from pits, rivers, seas and dredging, with each having distinct properties that make them suitable for different construction applications like plastering, masonry or concreting. Proper testing and grading of sand ensures it meets the necessary quality standards for use in various building works.