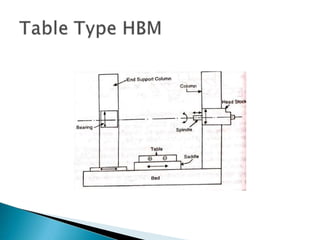

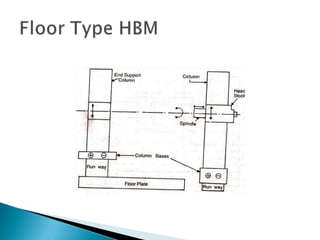

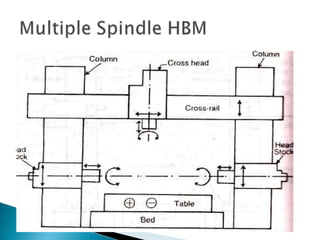

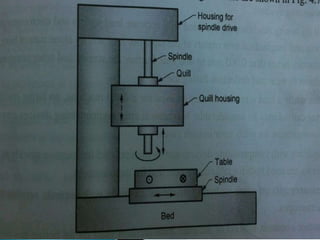

This document discusses different types of boring machines and their components. It describes horizontal boring machines, vertical boring machines, precision boring machines, and jig boring machines. It explains that horizontal boring machines can perform operations like boring, reaming, turning, threading, facing, milling and grooving. Vertical boring machines are used for heavy components and can also do drilling, reaming, threading, facing and grooving. Jig boring machines resemble vertical milling machines and are designed for accuracy through rigidity and precise measurement. The document also covers boring tool holders and different types of adjustable boring bars.