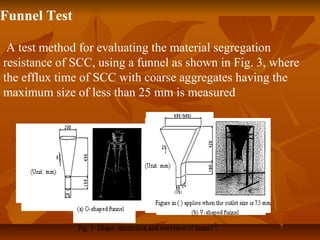

This document provides an overview of self-compacting concrete (SCC). It discusses how SCC was developed in the late 1980s in Japan to allow for concrete placement without vibration. SCC offers advantages like lower noise, easier placement, and improved quality. The document outlines common applications of SCC and test methods used to evaluate the flowability and segregation resistance of fresh SCC. It also summarizes research showing that hardened SCC has similar structural properties as high-performance vibrated concrete in terms of strength, modulus of elasticity, and bond strength.