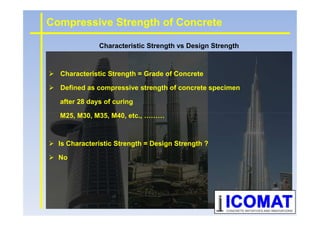

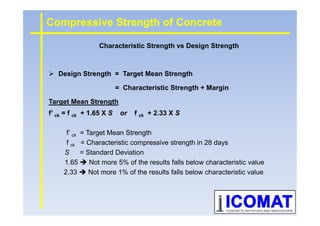

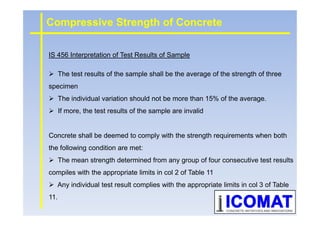

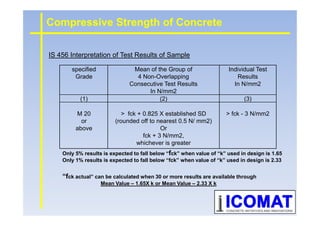

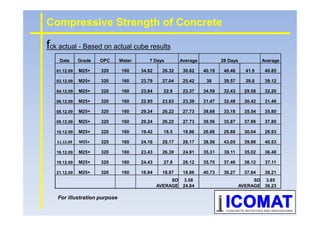

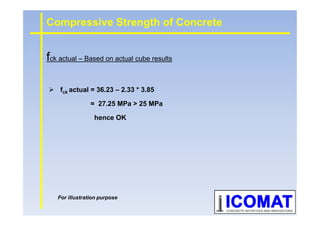

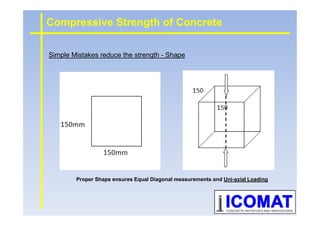

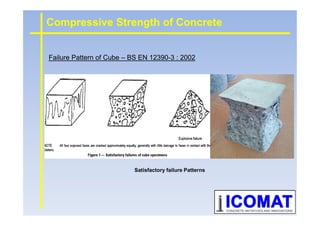

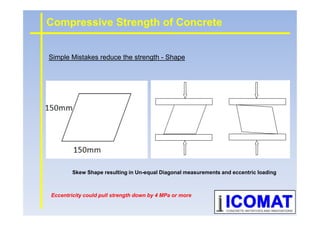

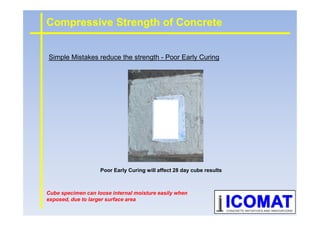

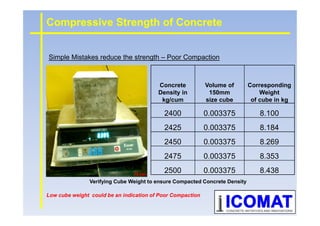

The document discusses the compressive strength of concrete, which is an important factor in designing reinforced concrete structures. Compressive strength is often used to measure the quality of concrete and is defined as the strength of concrete specimens after 28 days of curing. It is important for concrete mixes to meet the designated compressive strengths to ensure the structural integrity of buildings. The document outlines best practices for sampling, curing, transporting, and testing concrete cubes to accurately determine compressive strength.