1. The document describes a slump test performed on a concrete sample to determine its consistency and workability.

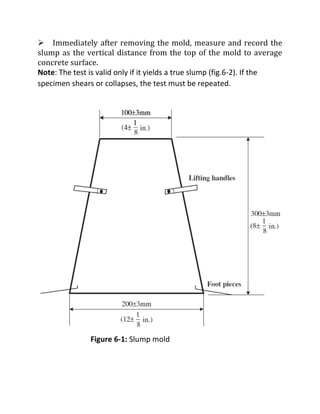

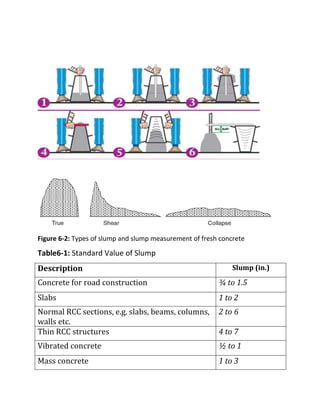

2. The test involved filling a slump mold in 3 layers and tamping each layer, then measuring the amount the concrete slumps after removing the mold.

3. The results showed that adding a superplasticizer or increasing the water content increased the slump, indicating better workability, while a sample with a low water content had poor workability as indicated by a low slump.