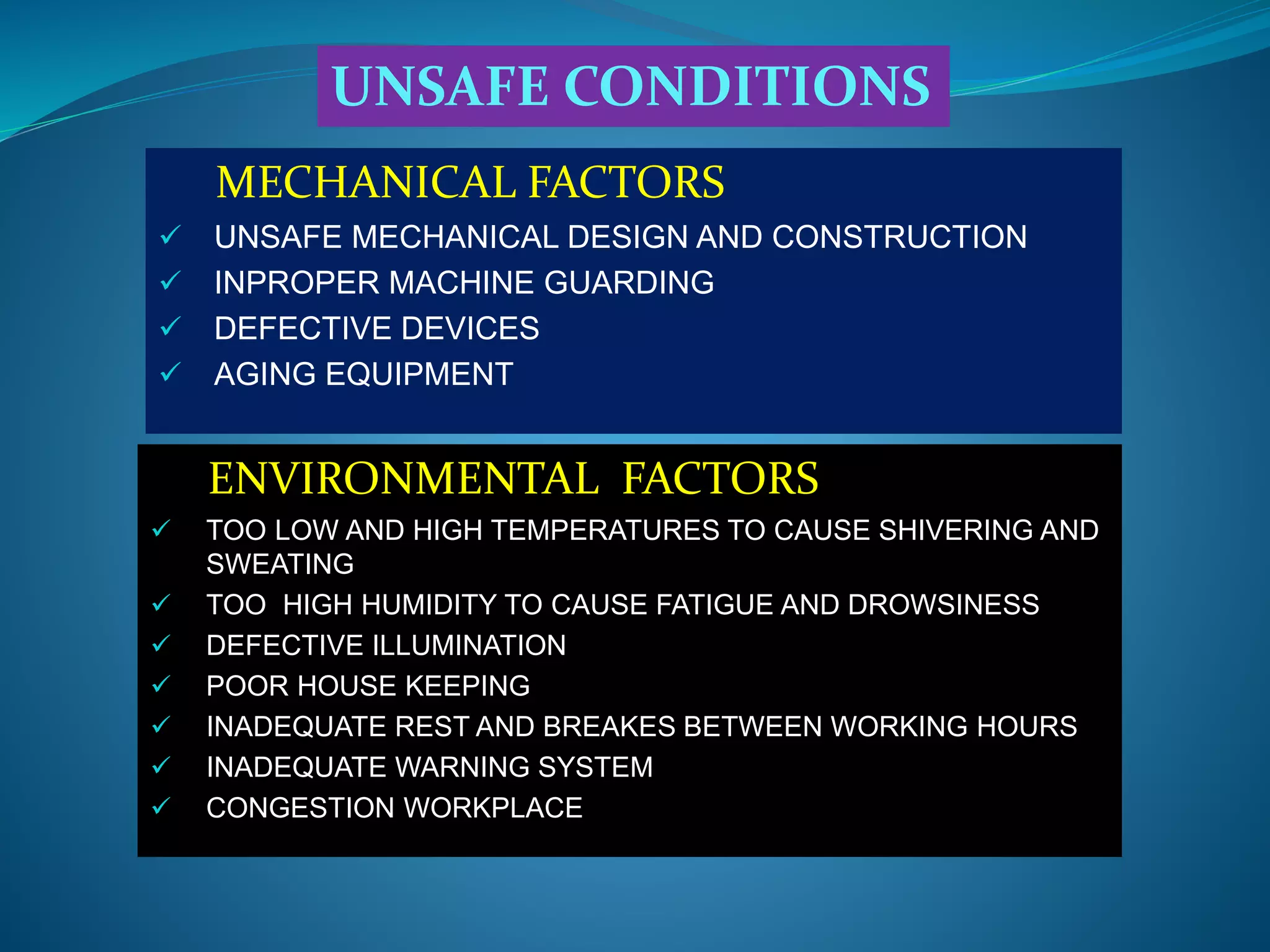

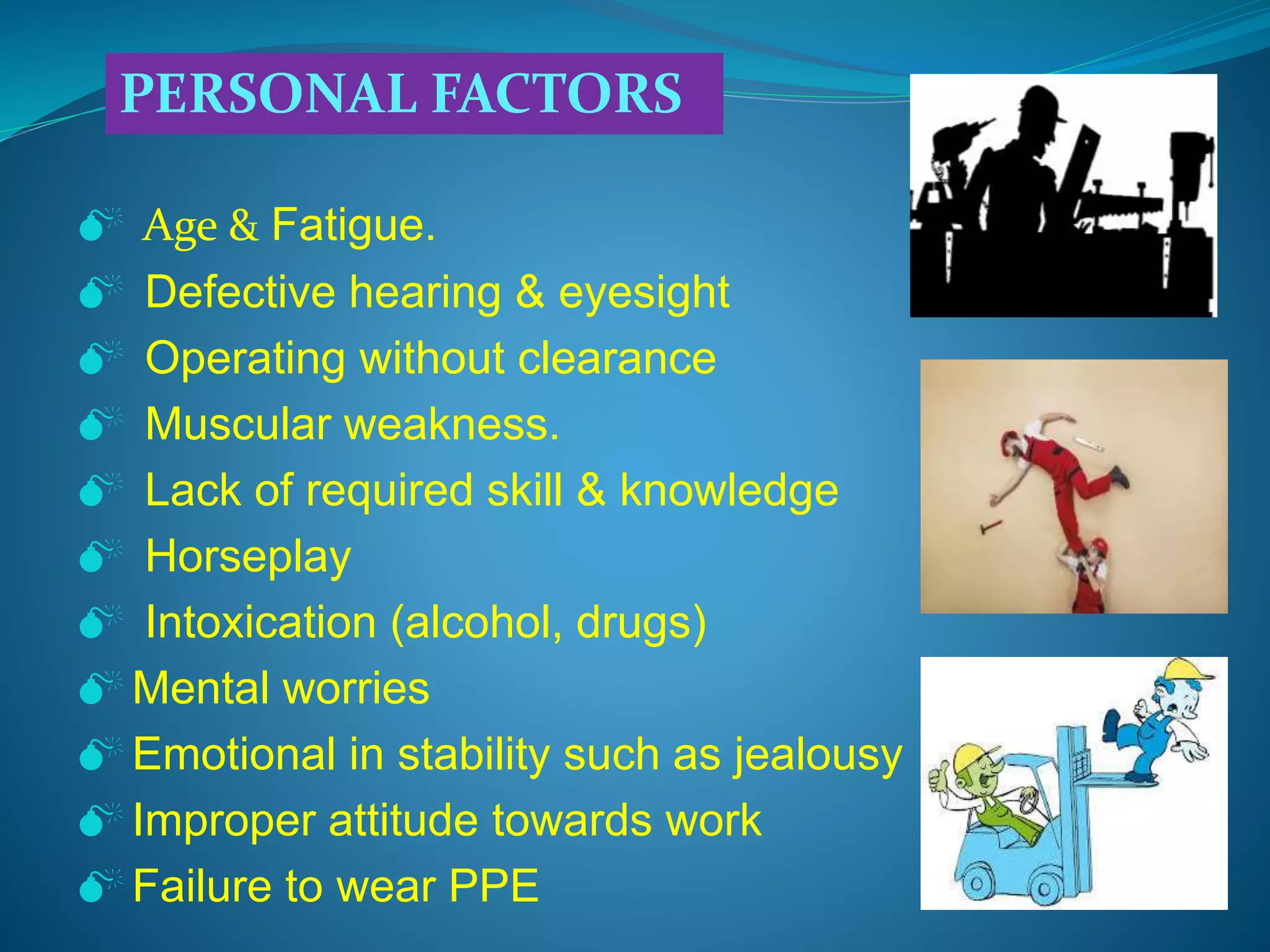

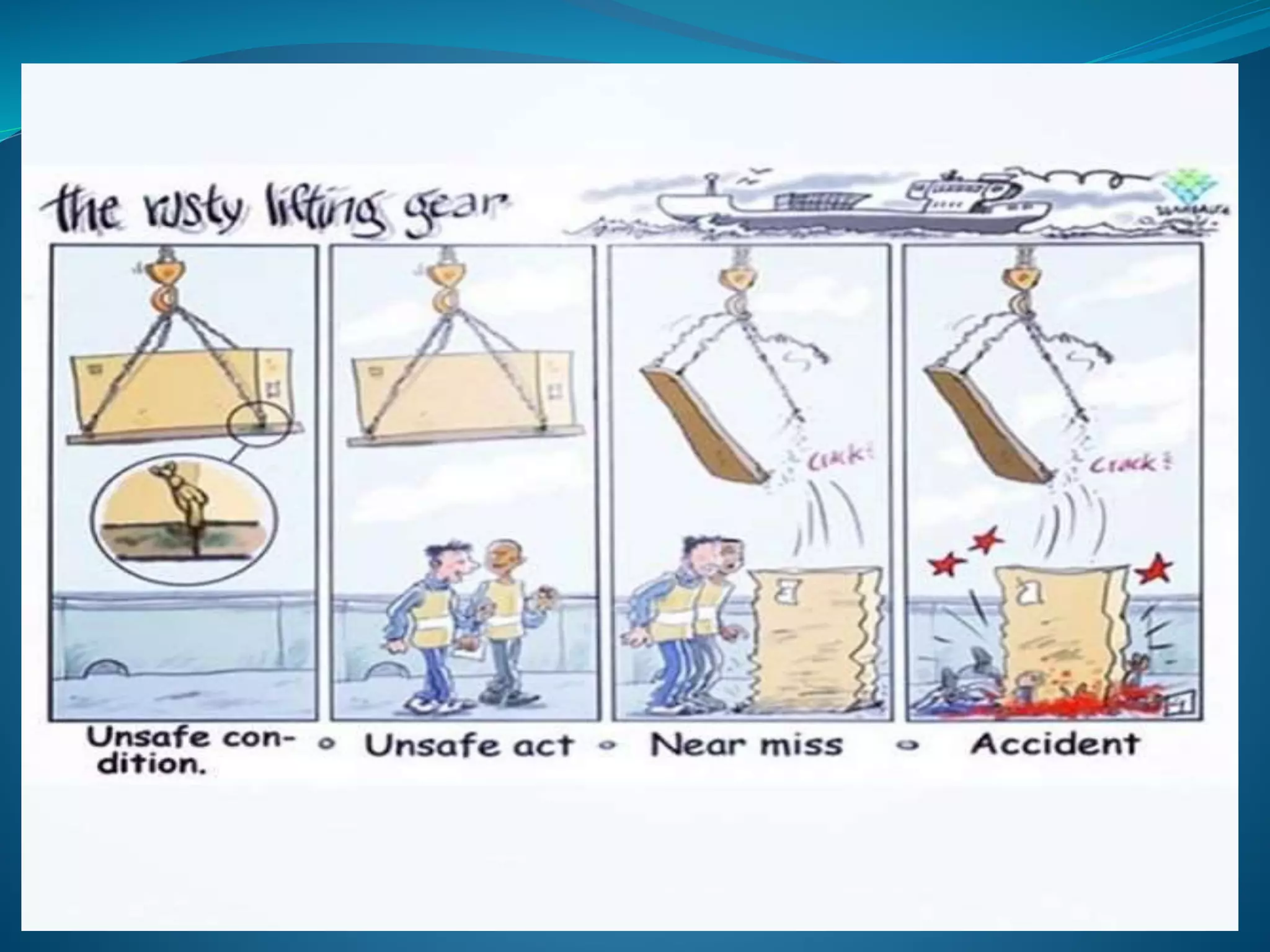

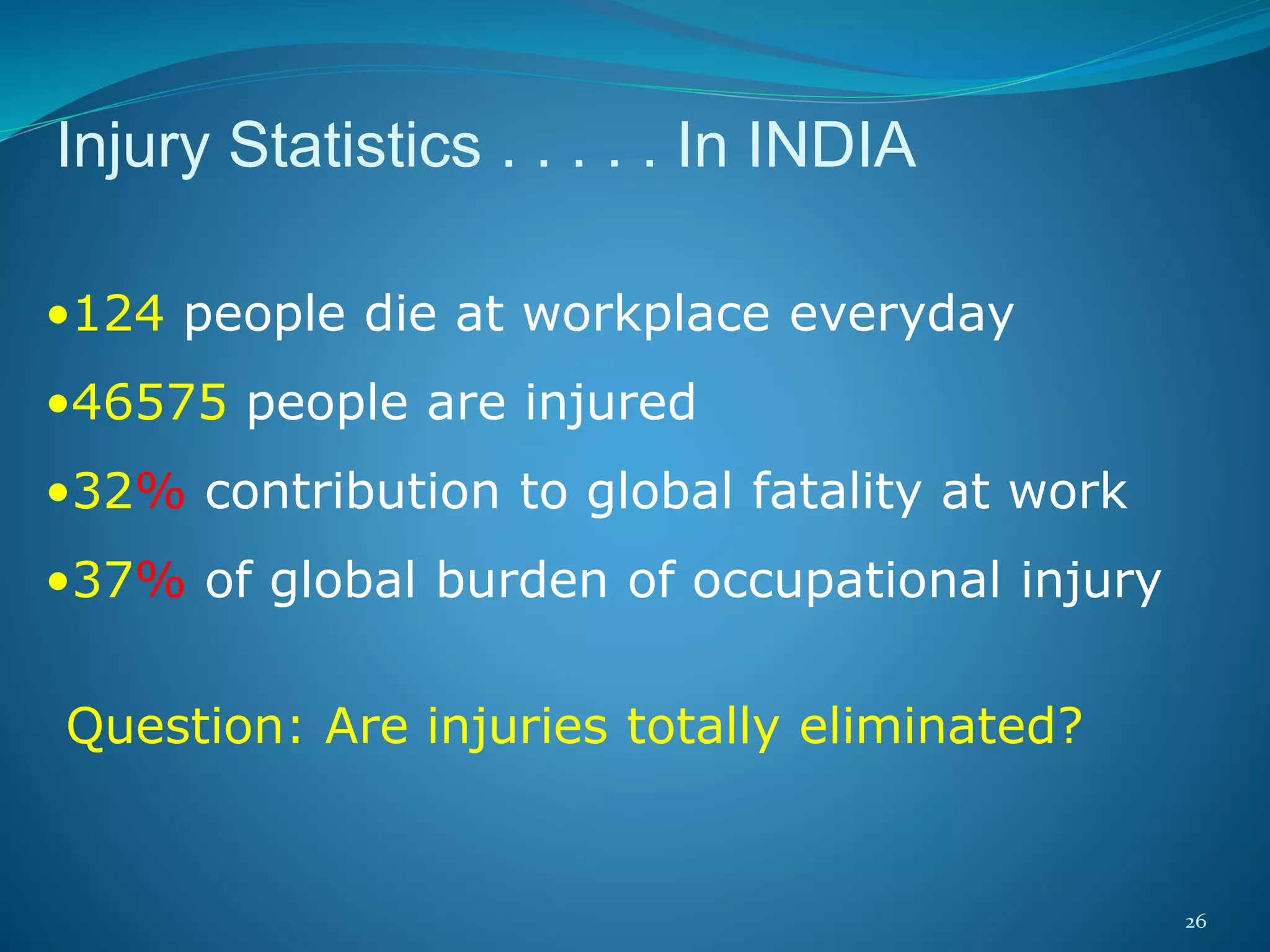

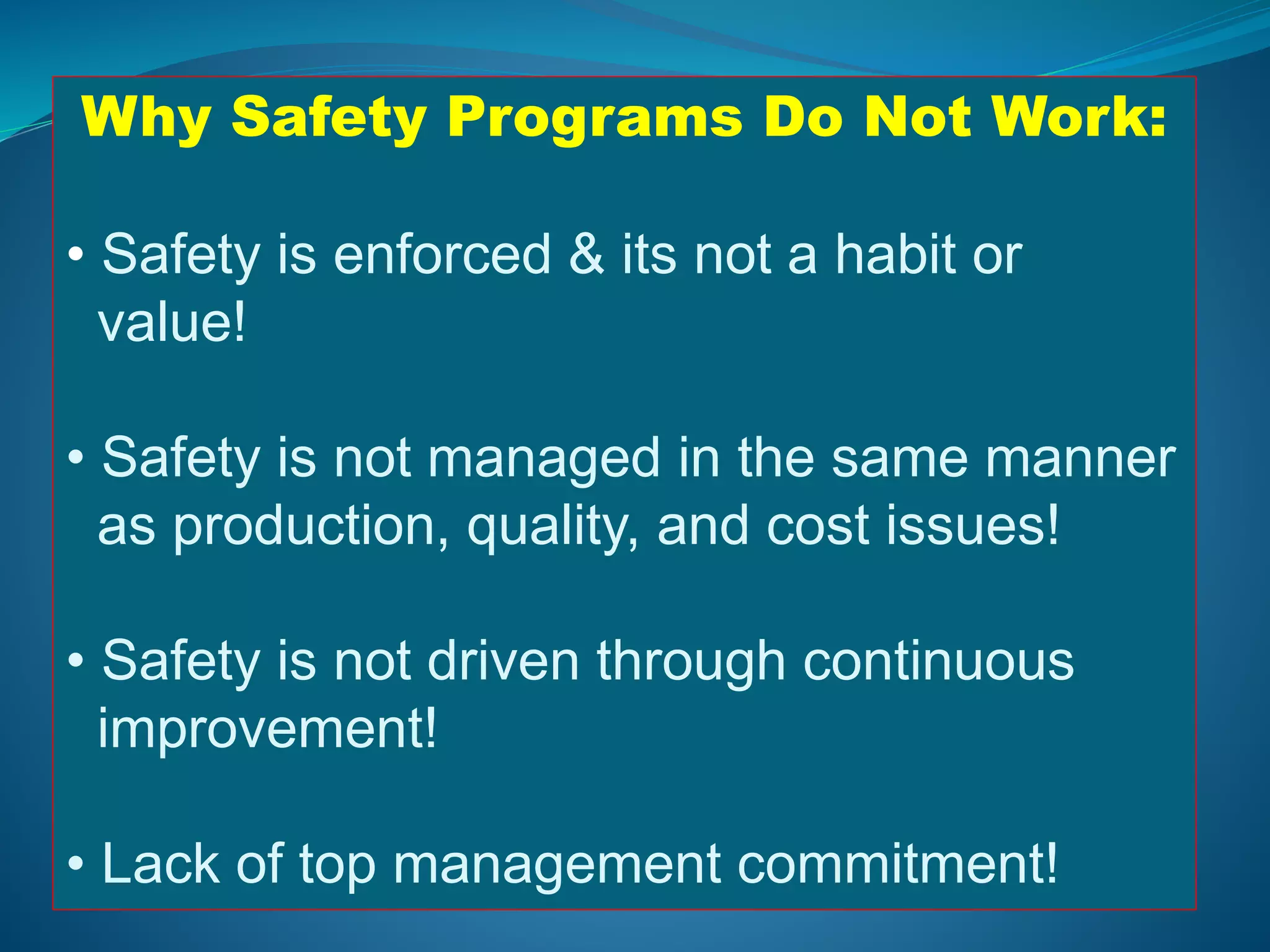

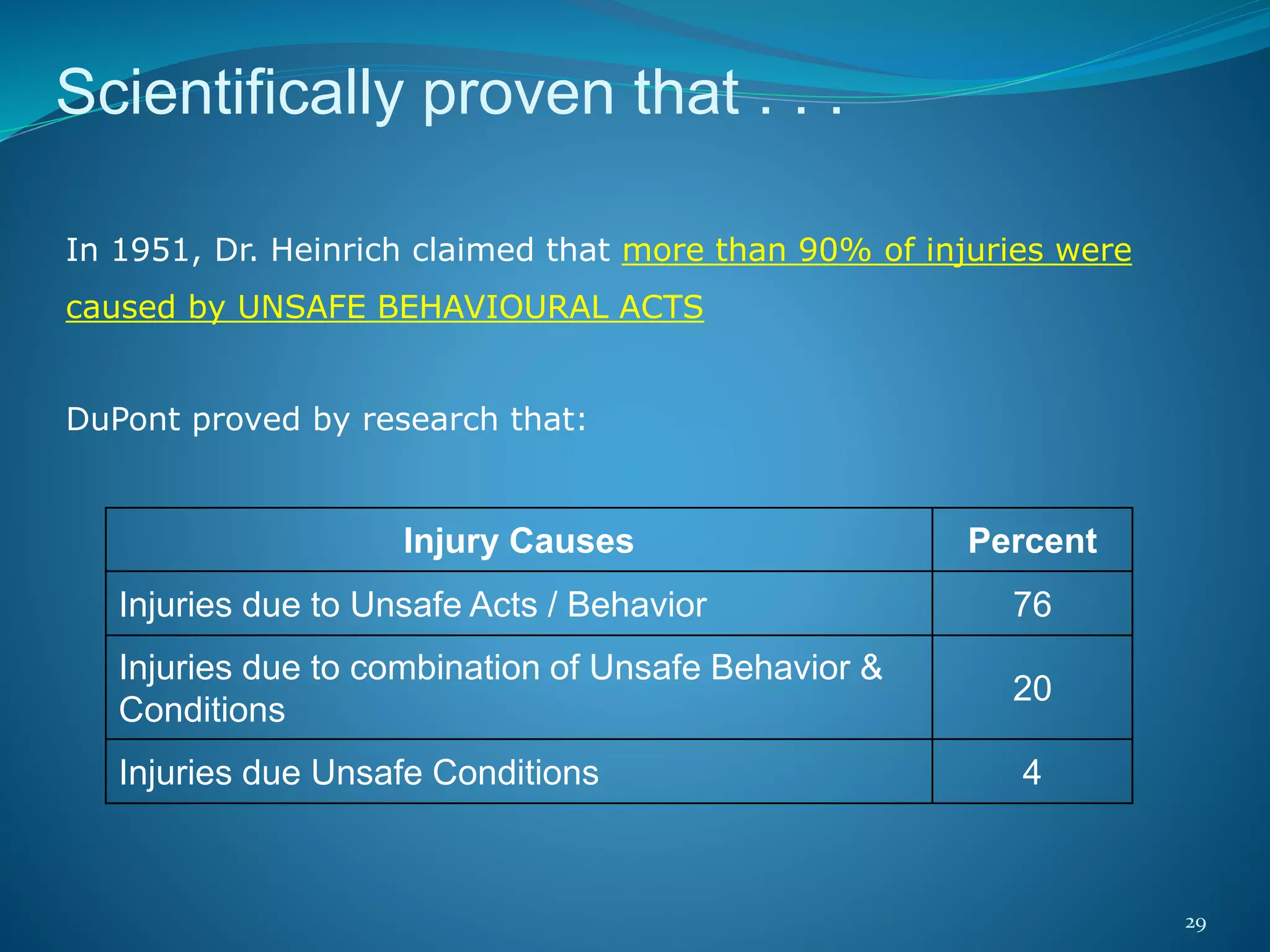

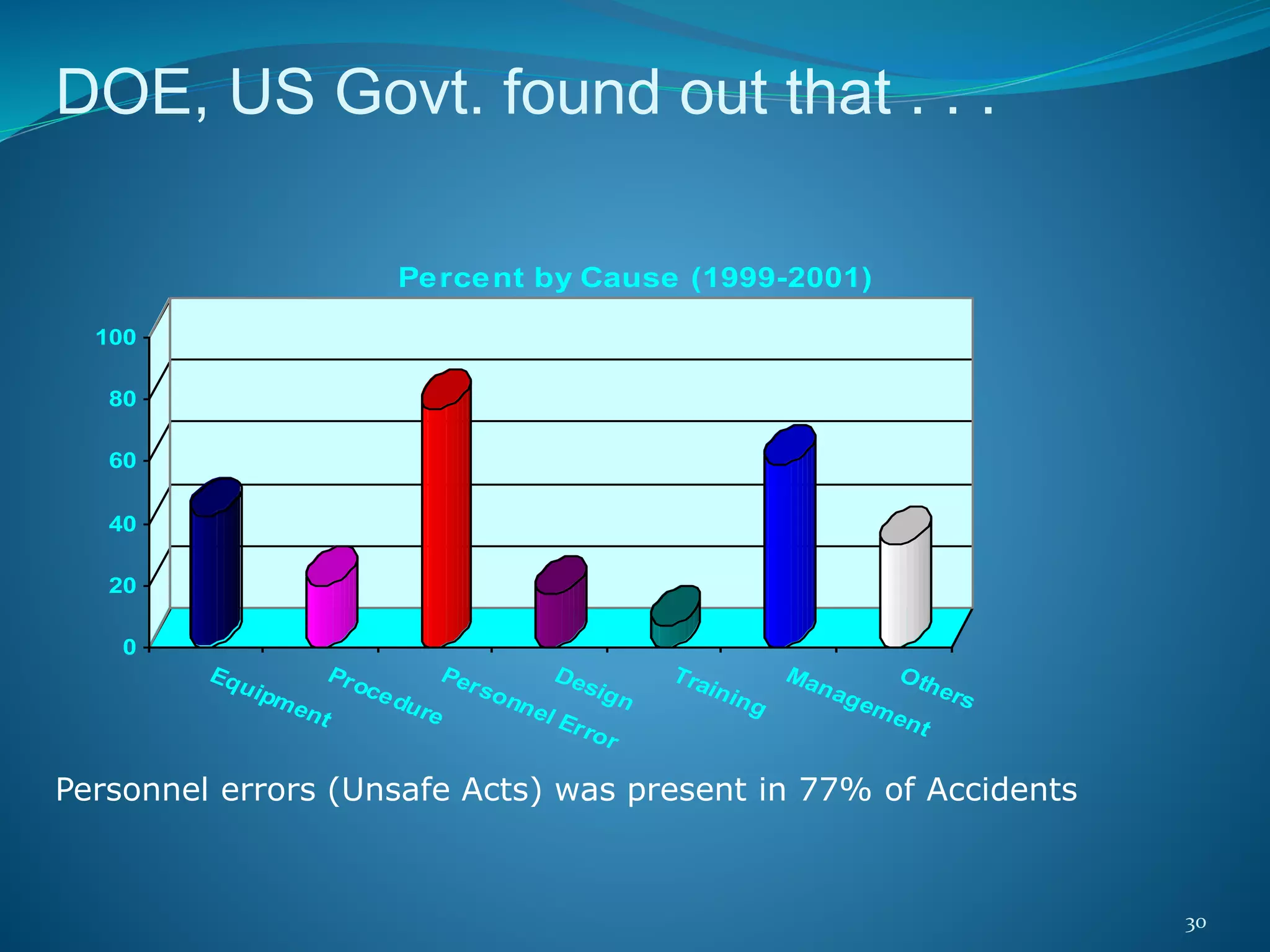

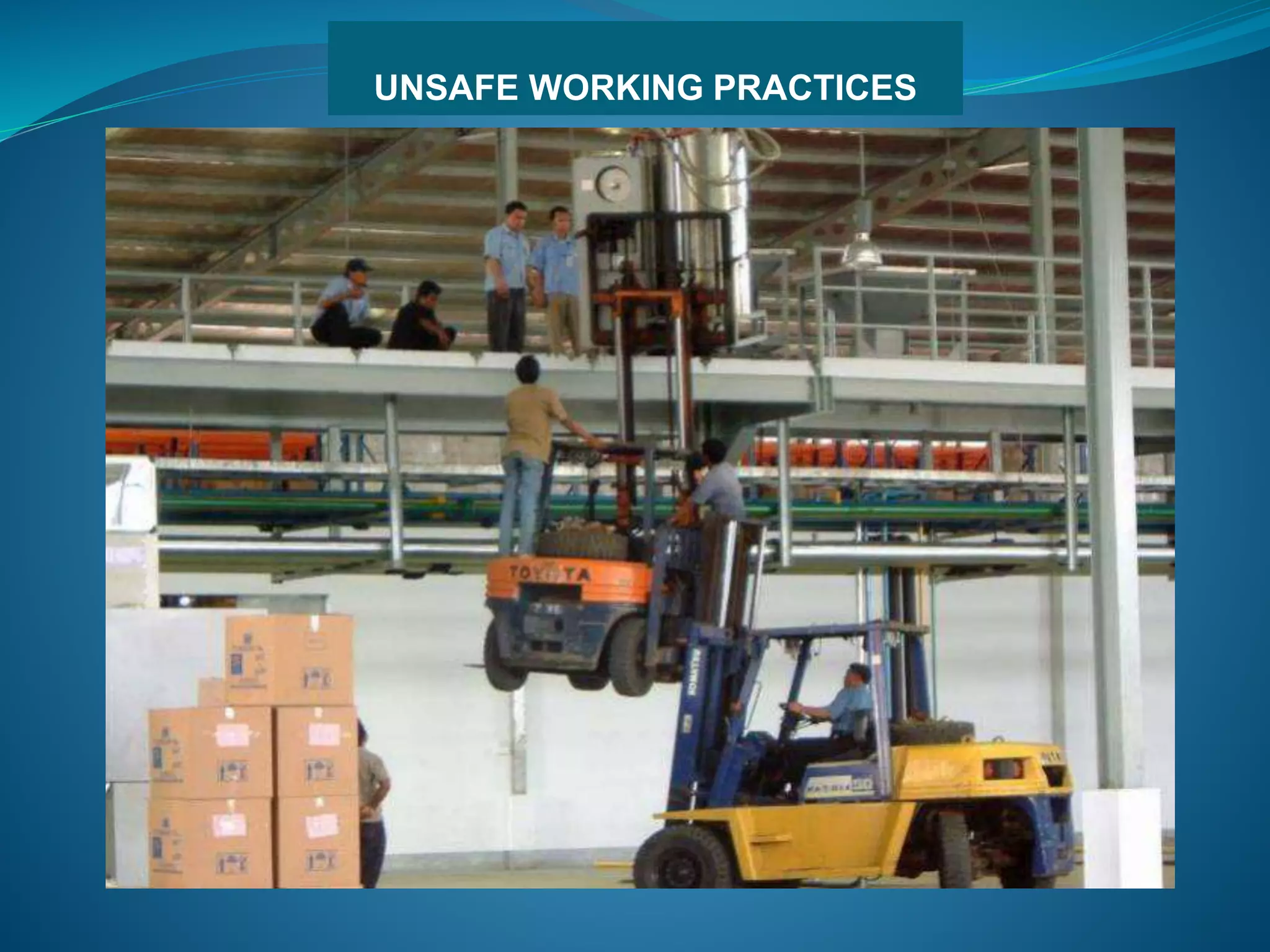

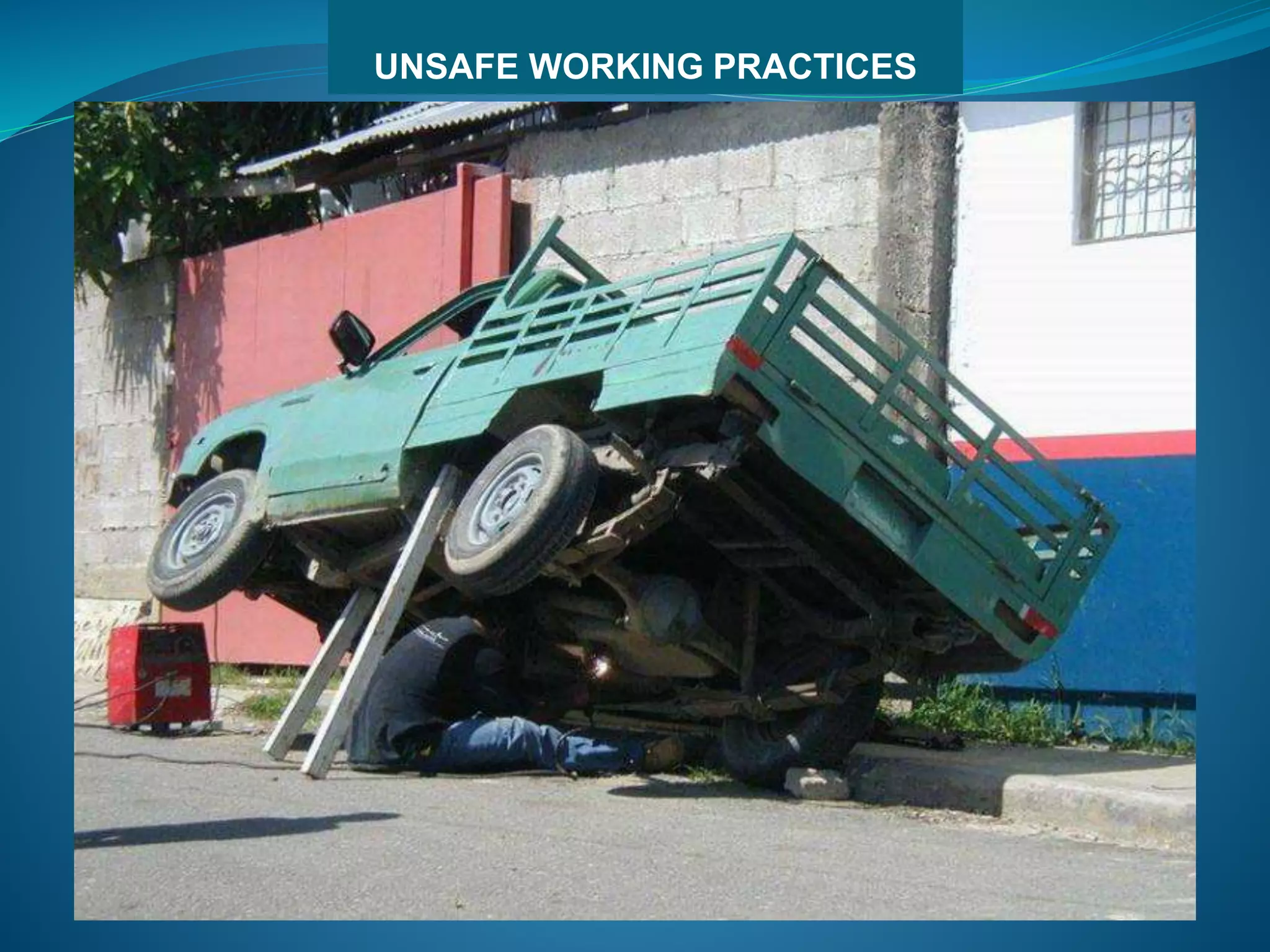

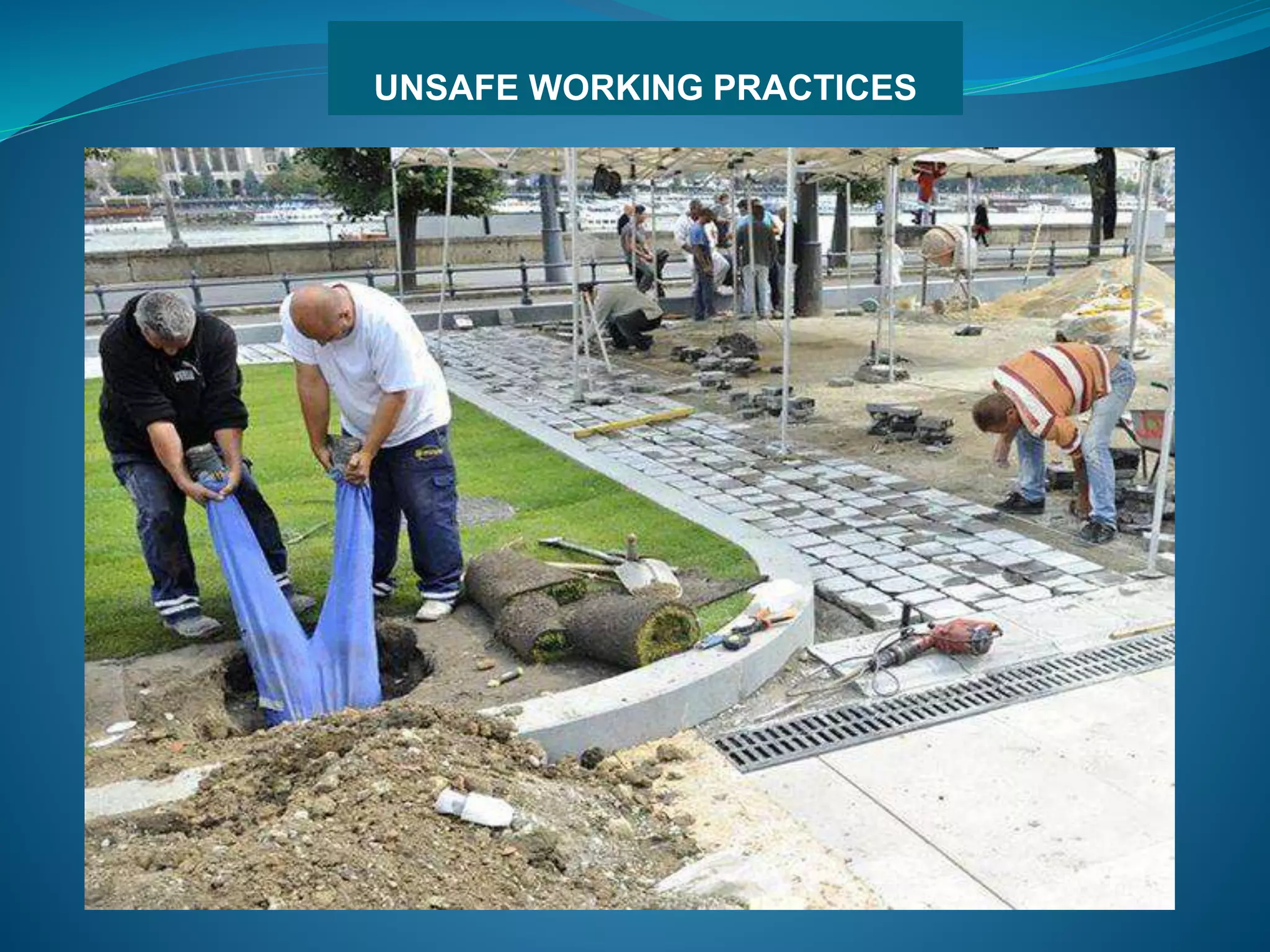

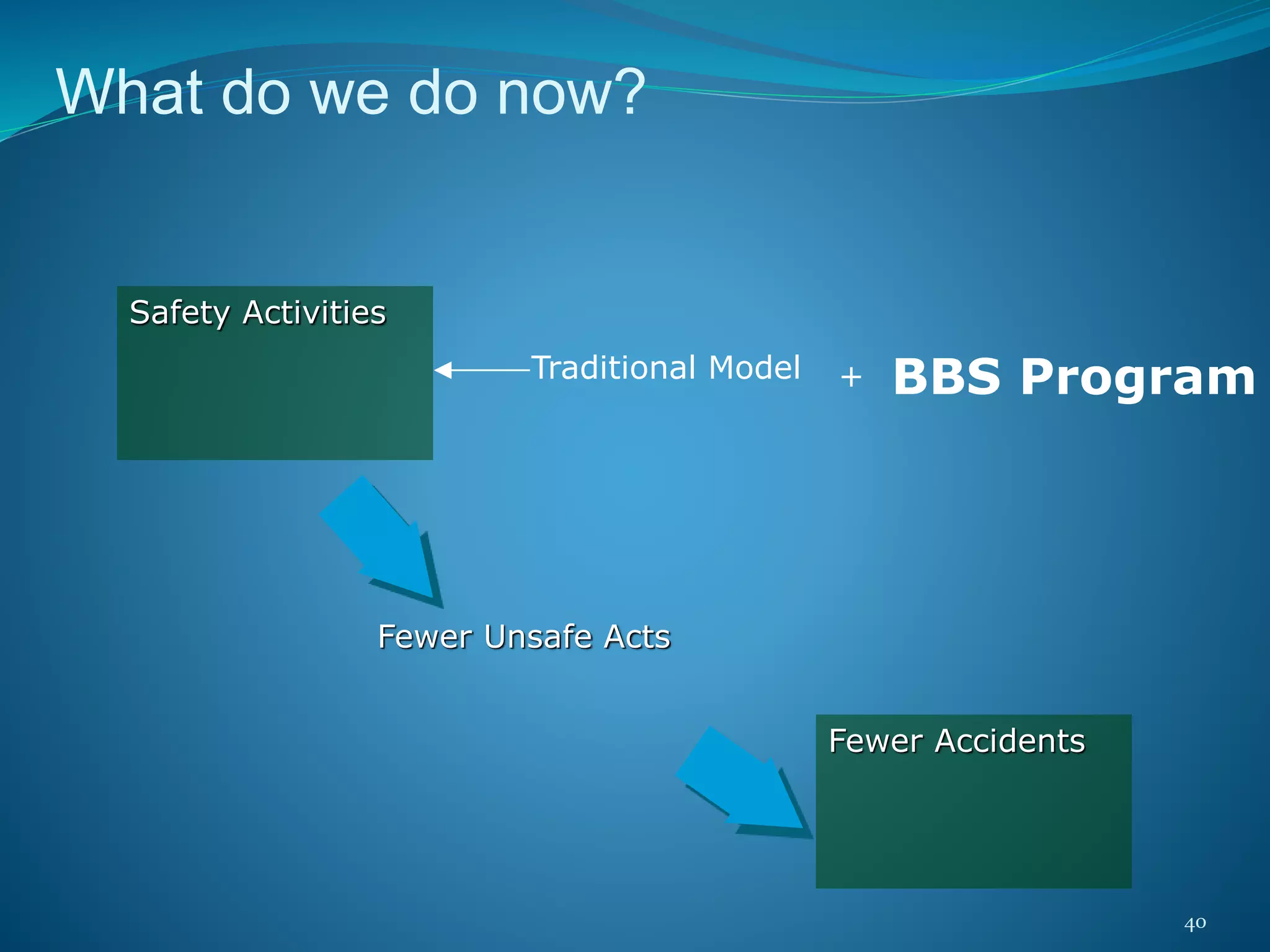

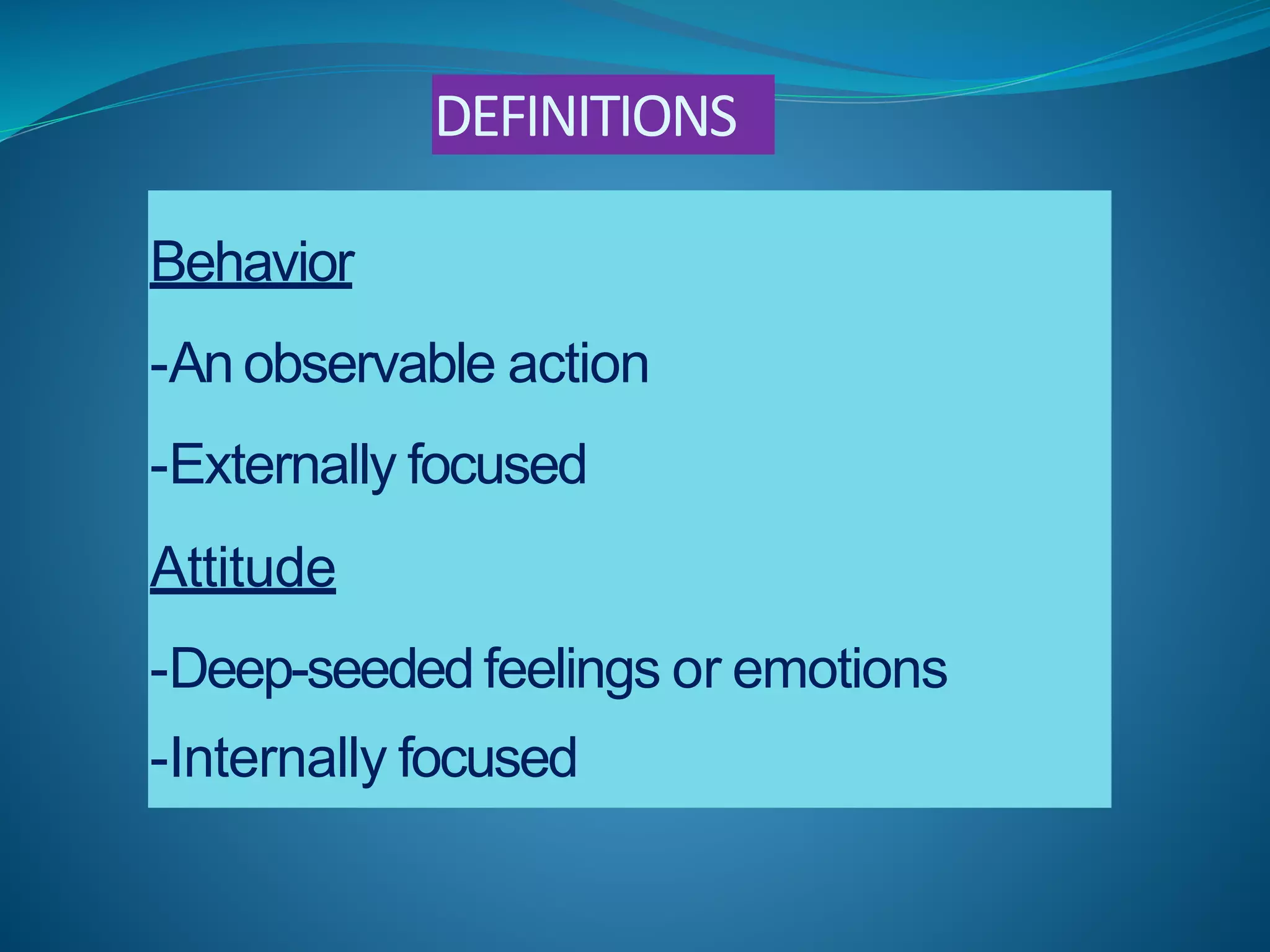

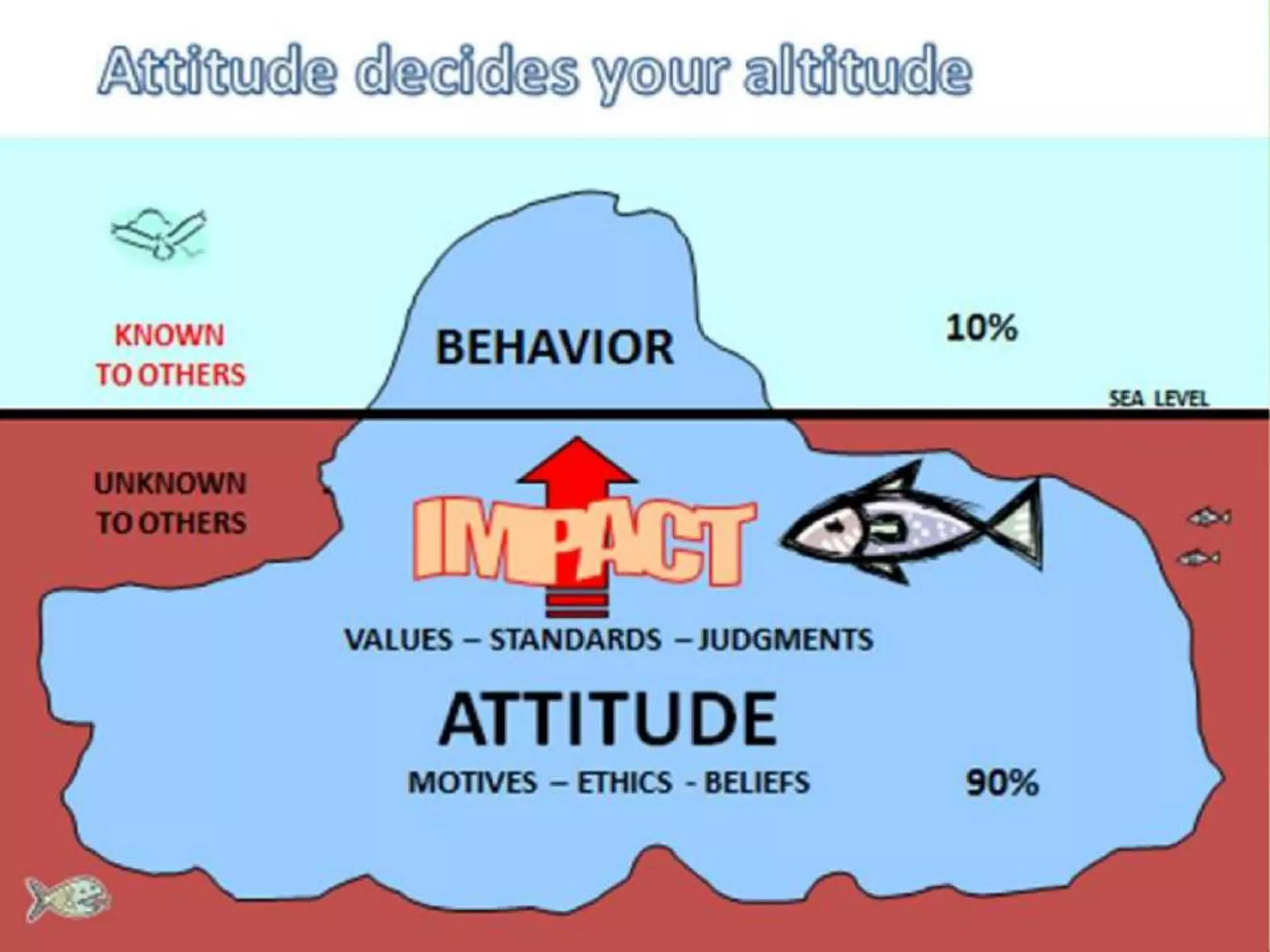

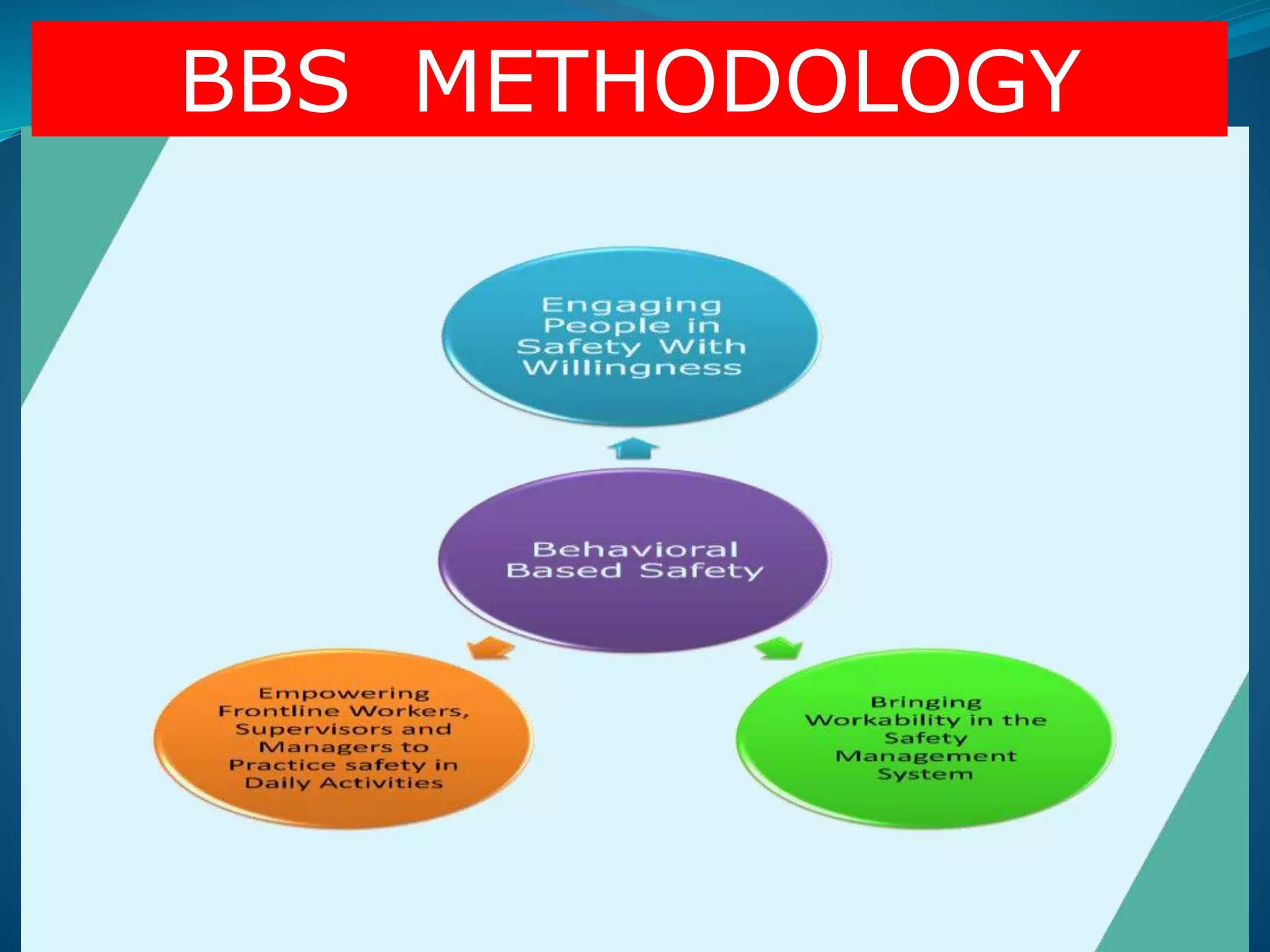

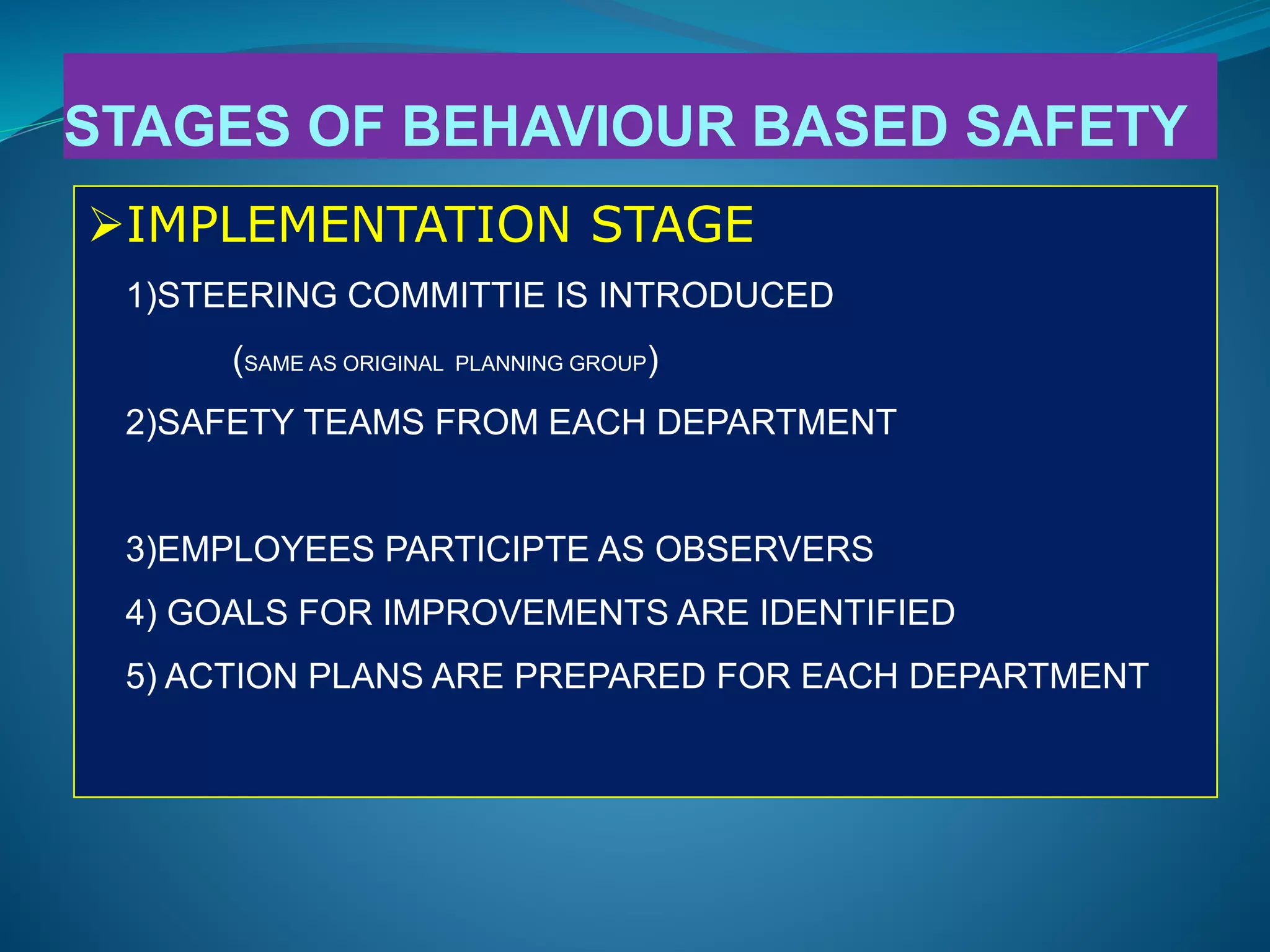

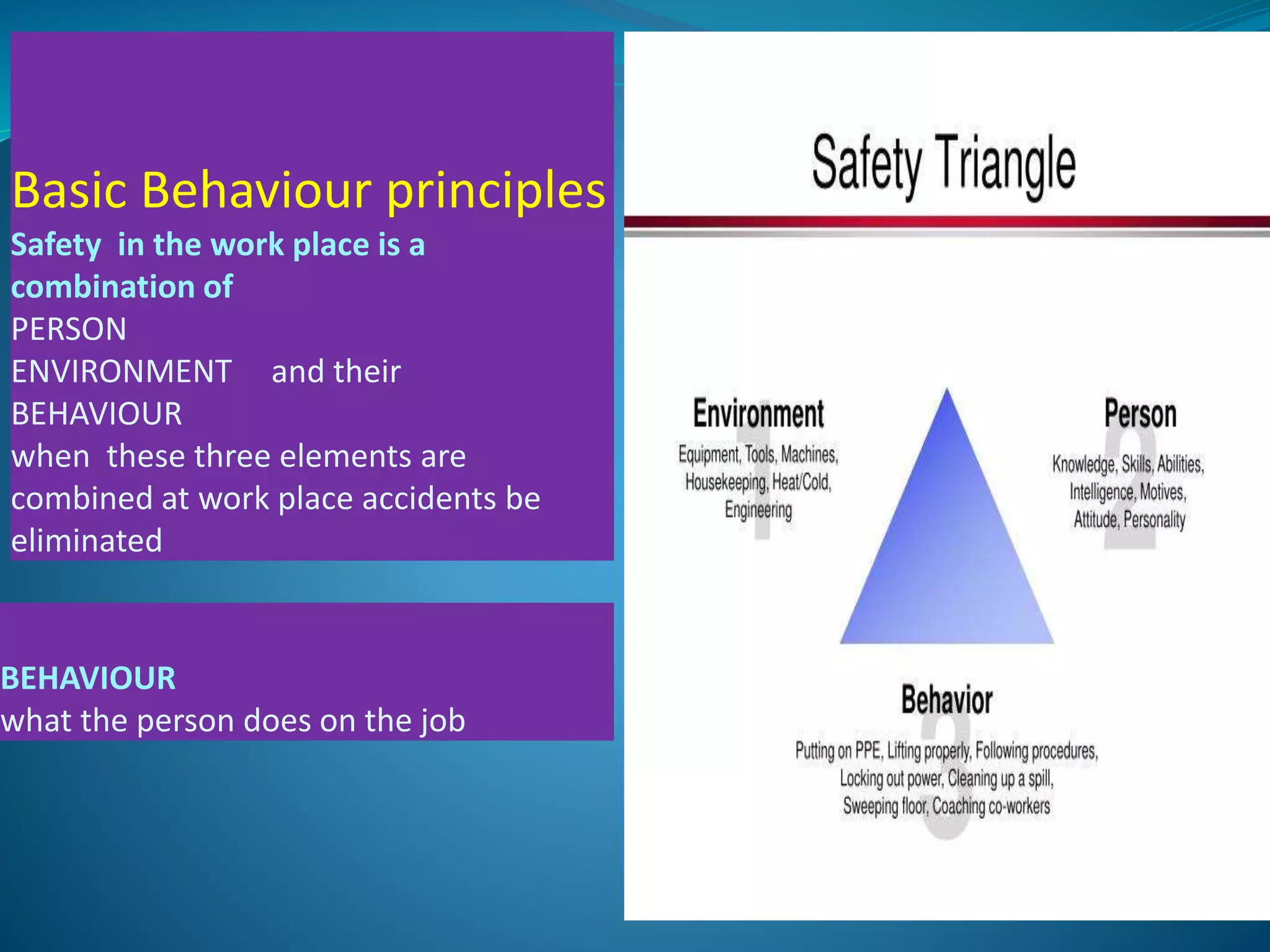

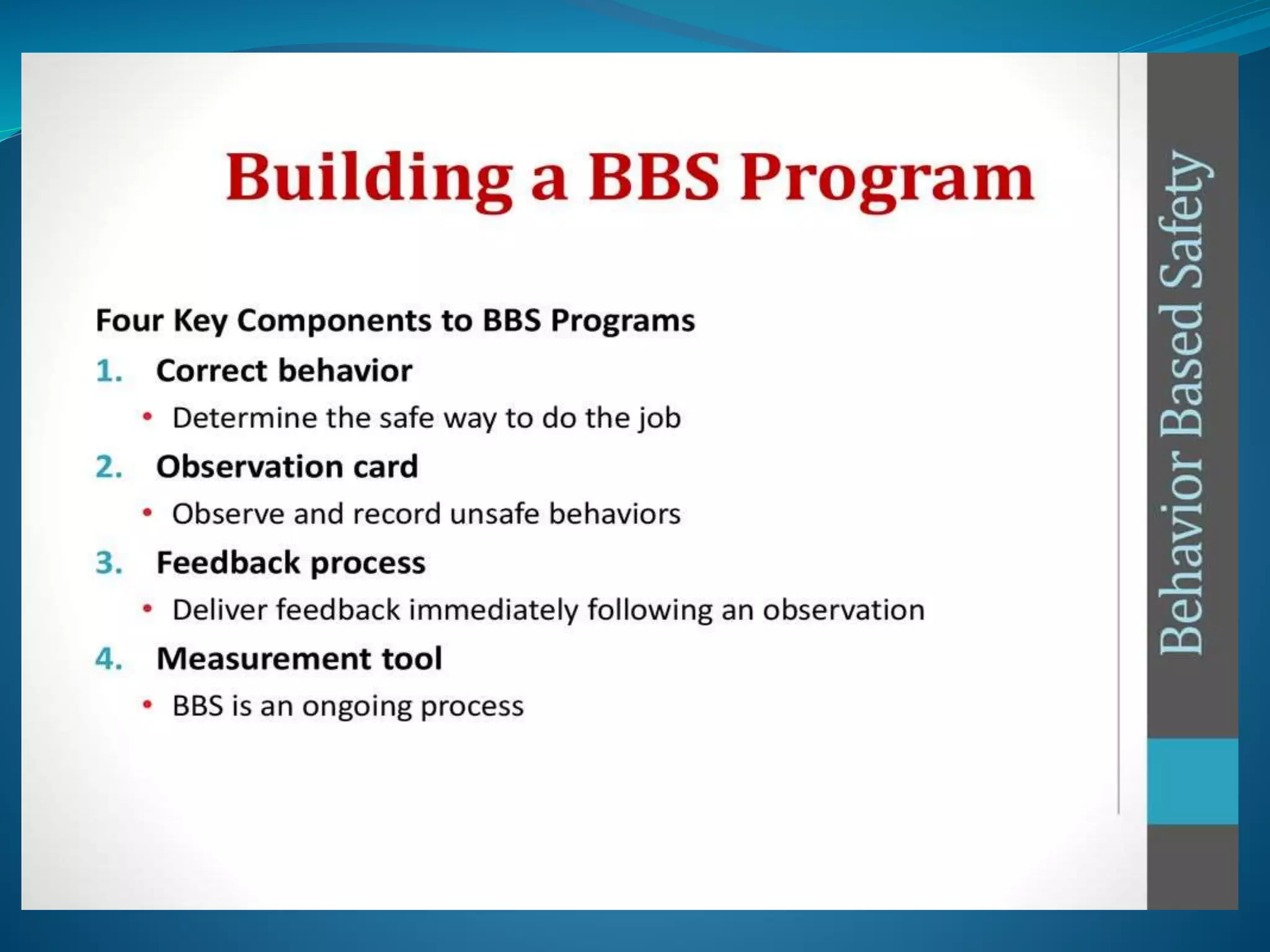

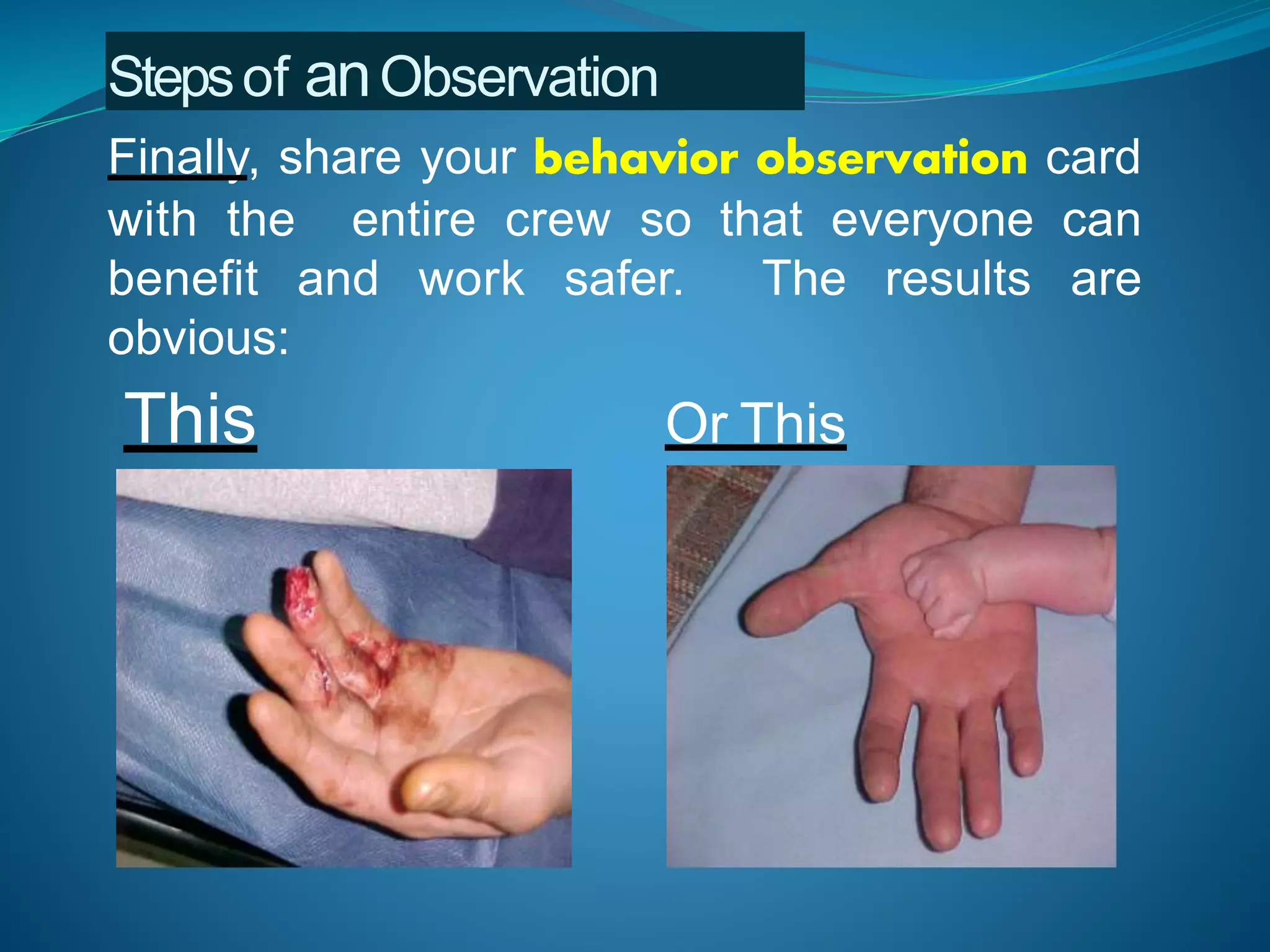

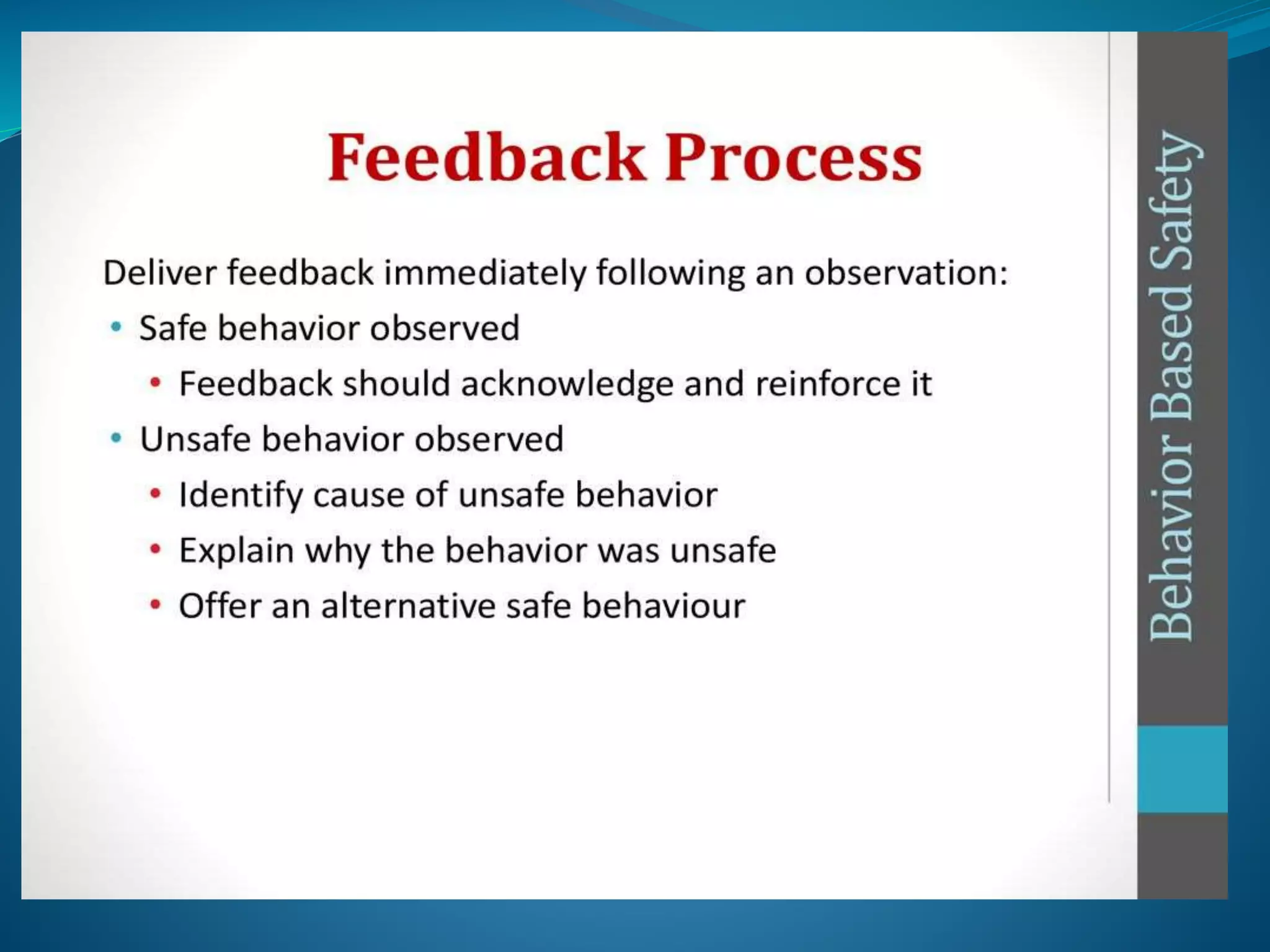

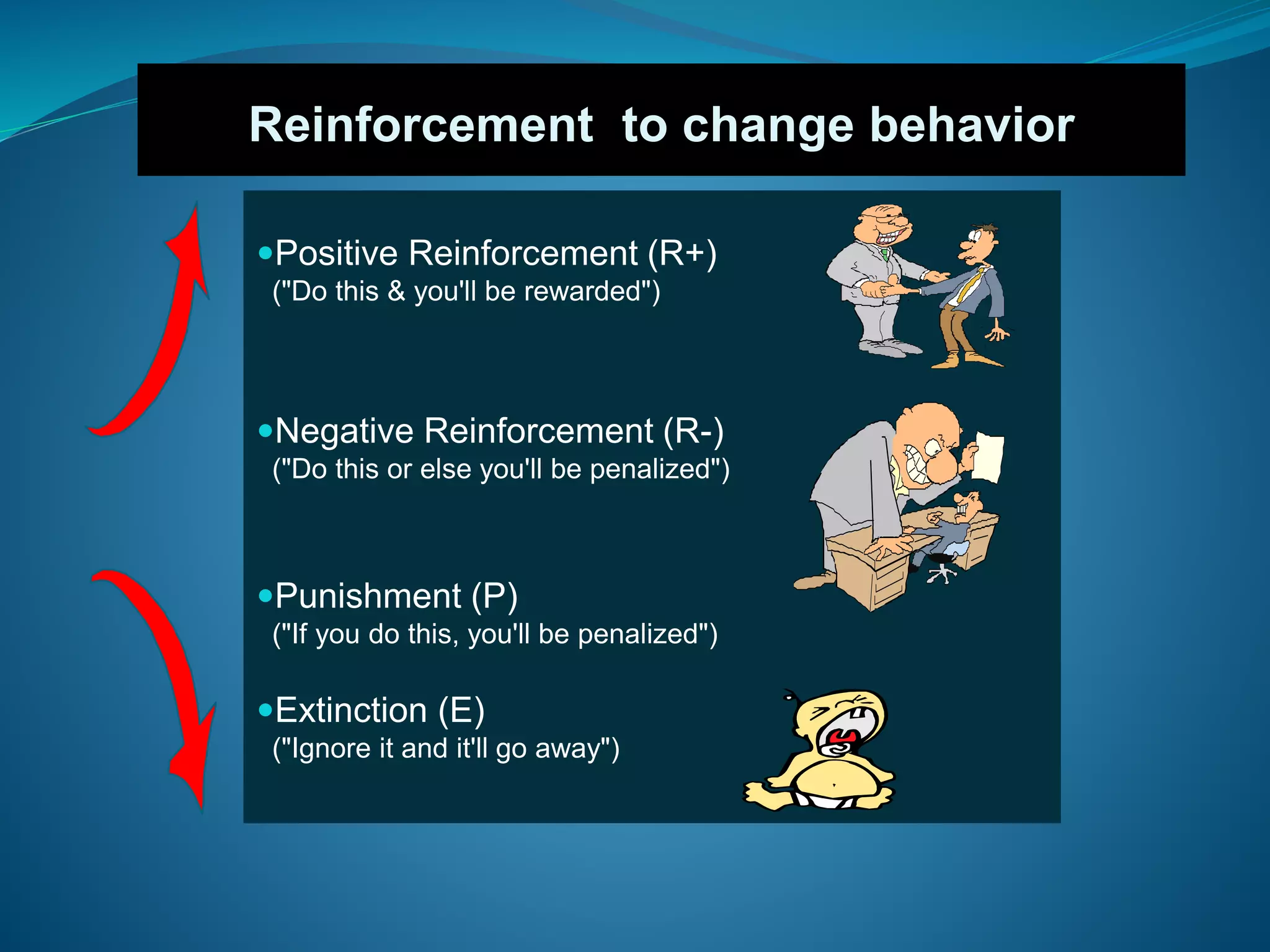

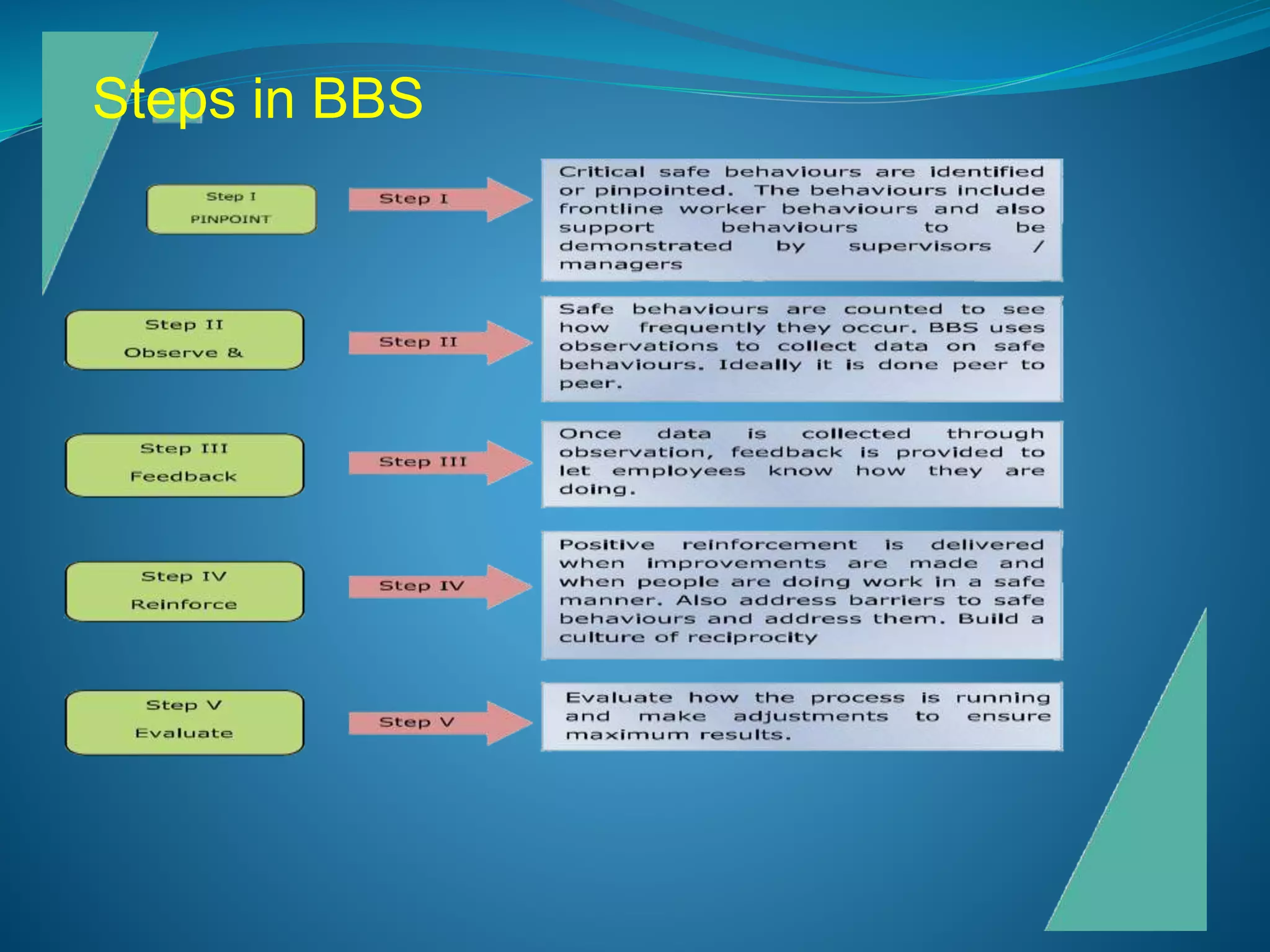

This document provides an overview of Behavior Based Safety (BBS) and how it can help prevent accidents in industries. It begins by asking what BBS is and explaining that traditional safety programs have limited effectiveness because they are typically top-down and focus on regulations rather than changing behaviors. Most accidents are caused by unsafe behavioral acts rather than unsafe conditions. BBS aims to minimize injuries by making safety a habit through employee involvement and feedback to change behaviors and ultimately attitudes. The methodology involves planning, implementation with safety teams and employee observations to identify and reinforce safe behaviors while stopping unsafe acts. The benefits of BBS include reduction in injuries, costs and investigations as well as increased productivity. It requires long-term management support and employee cooperation to be