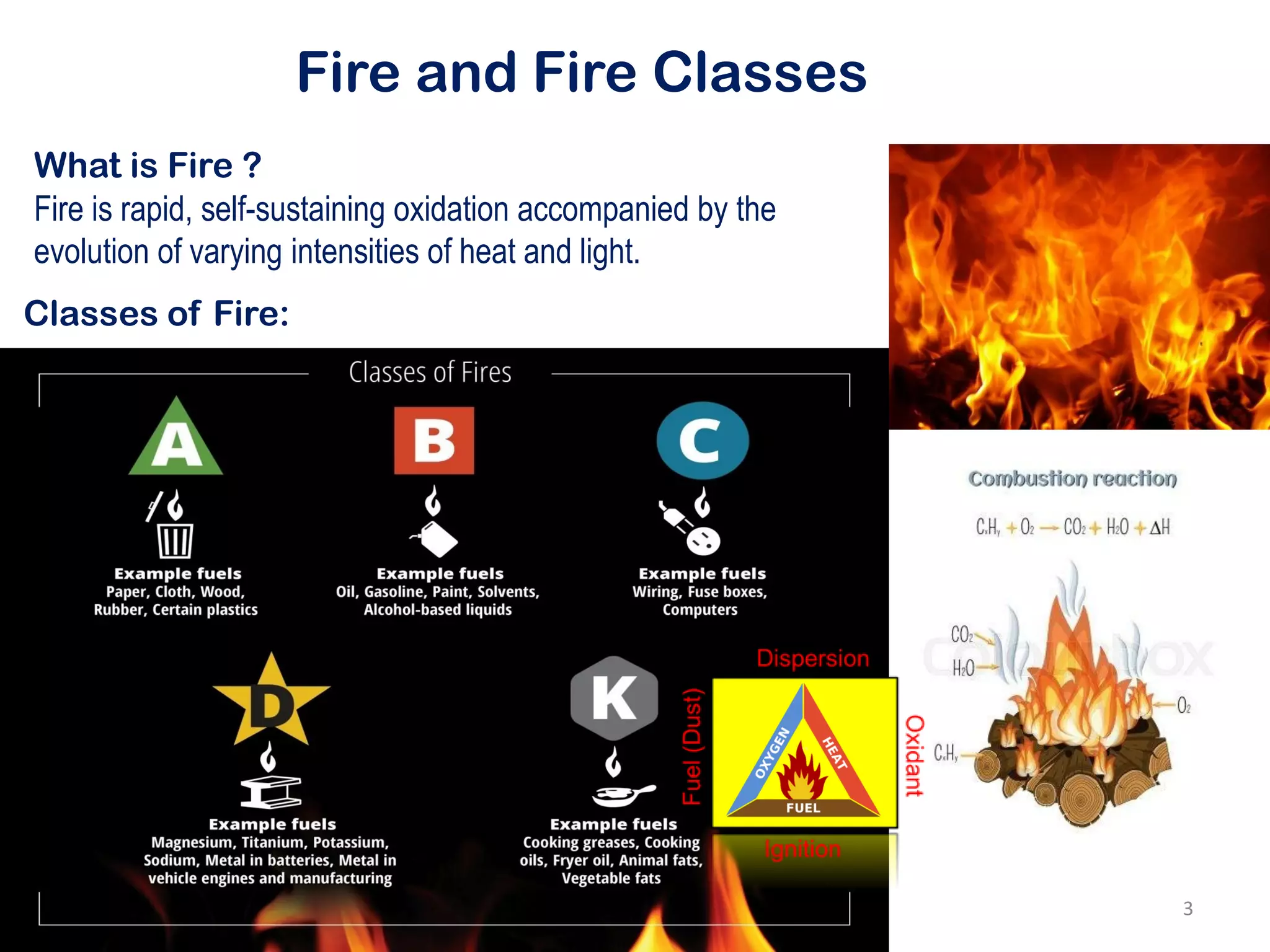

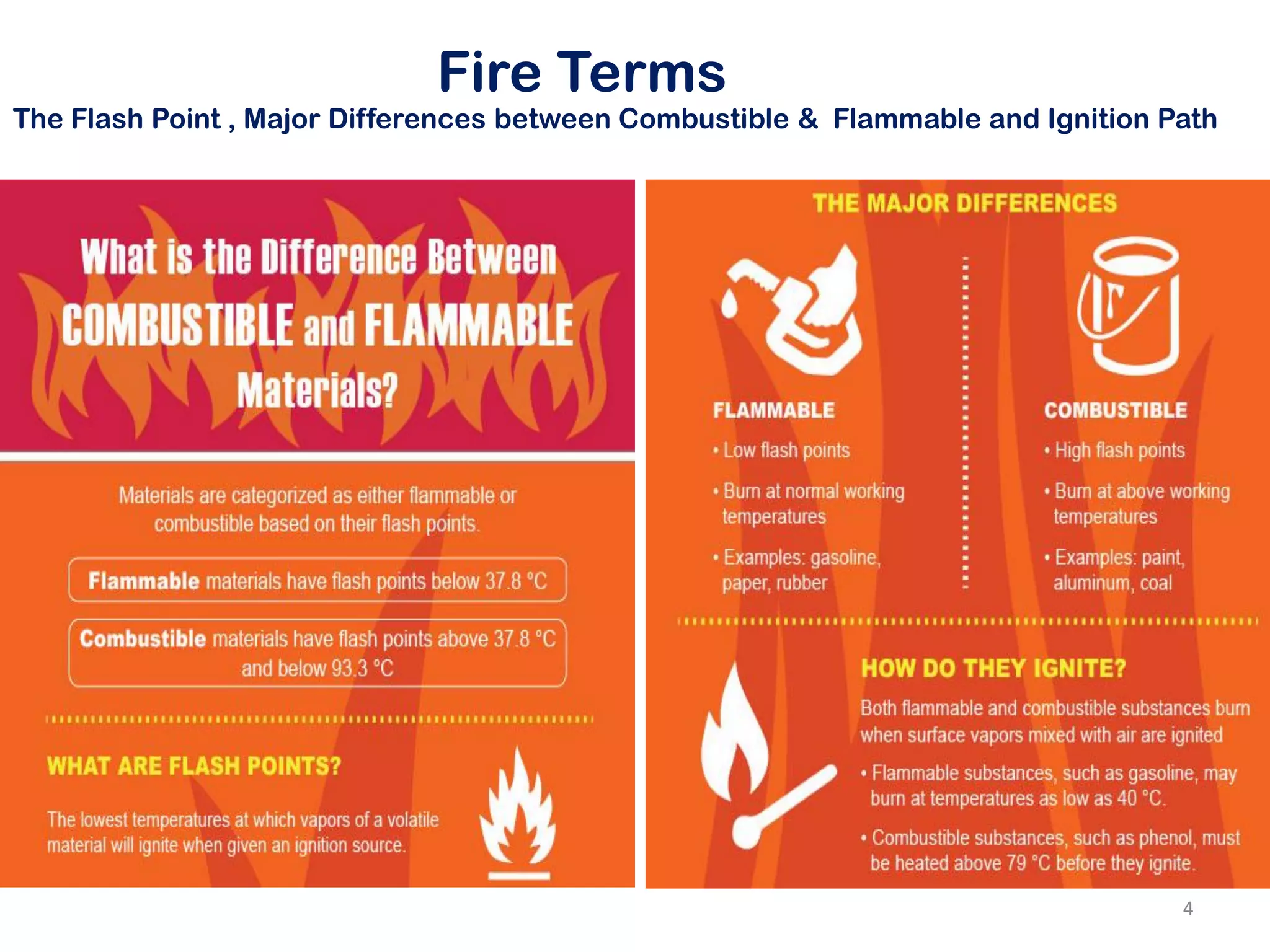

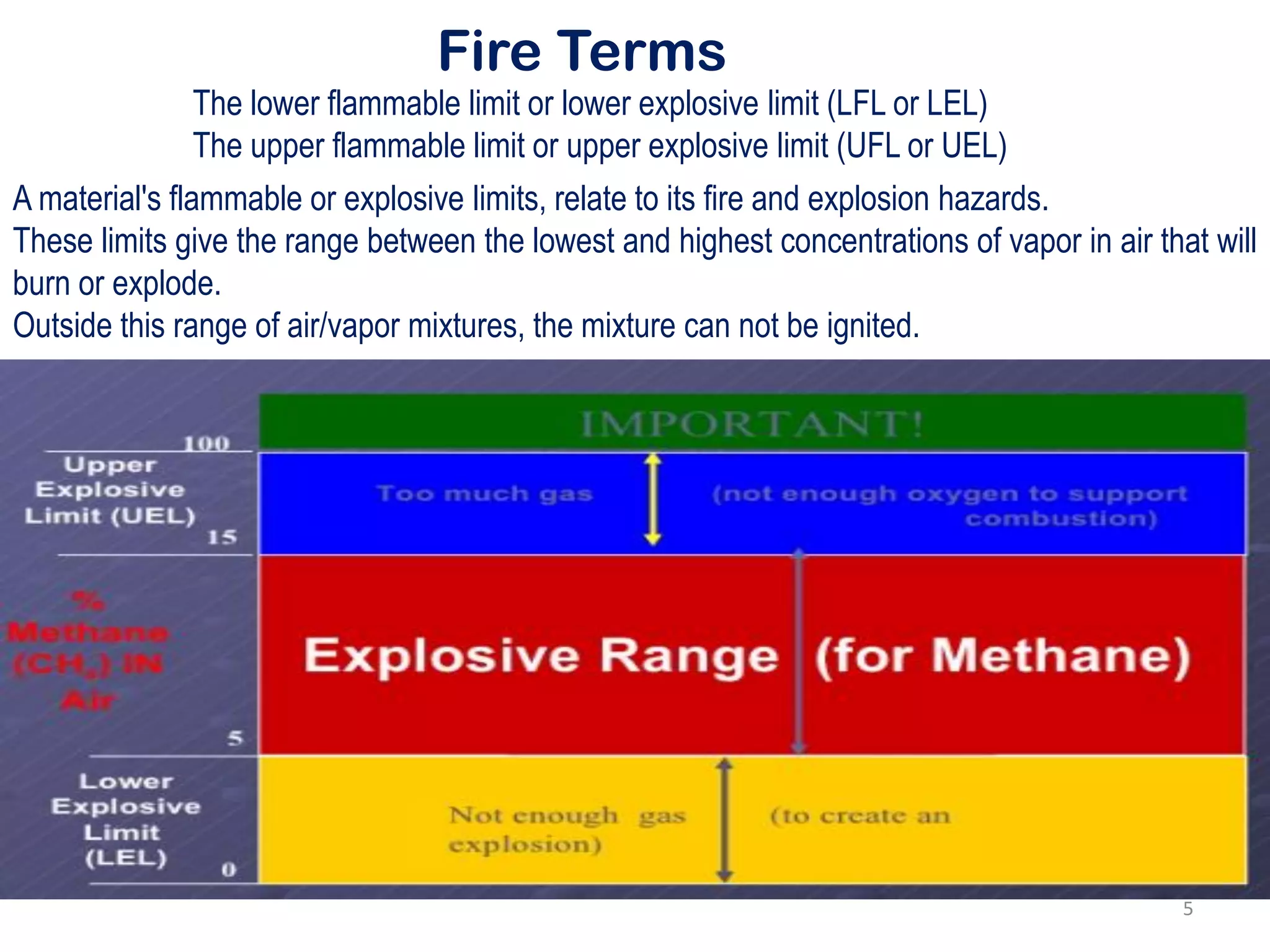

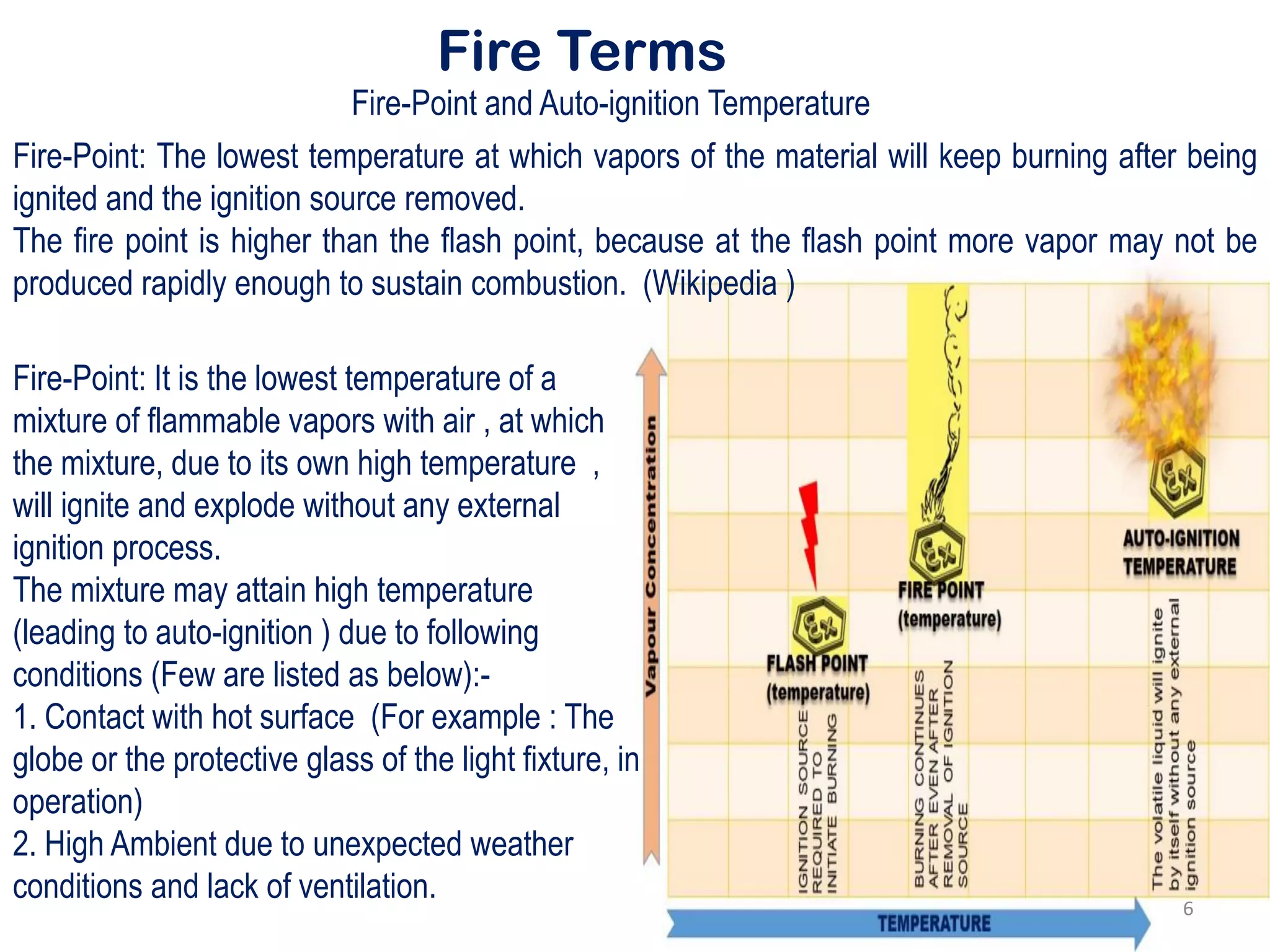

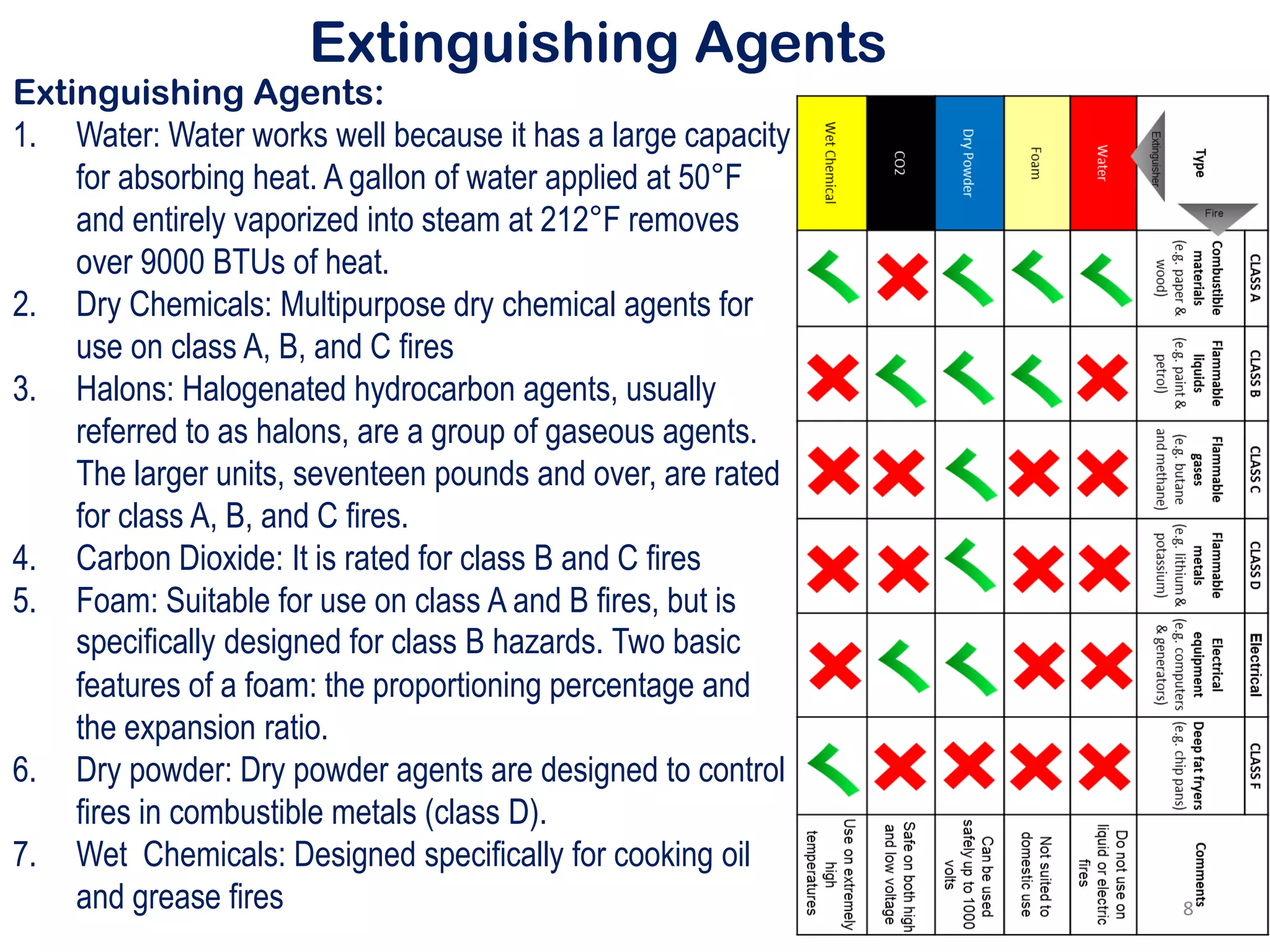

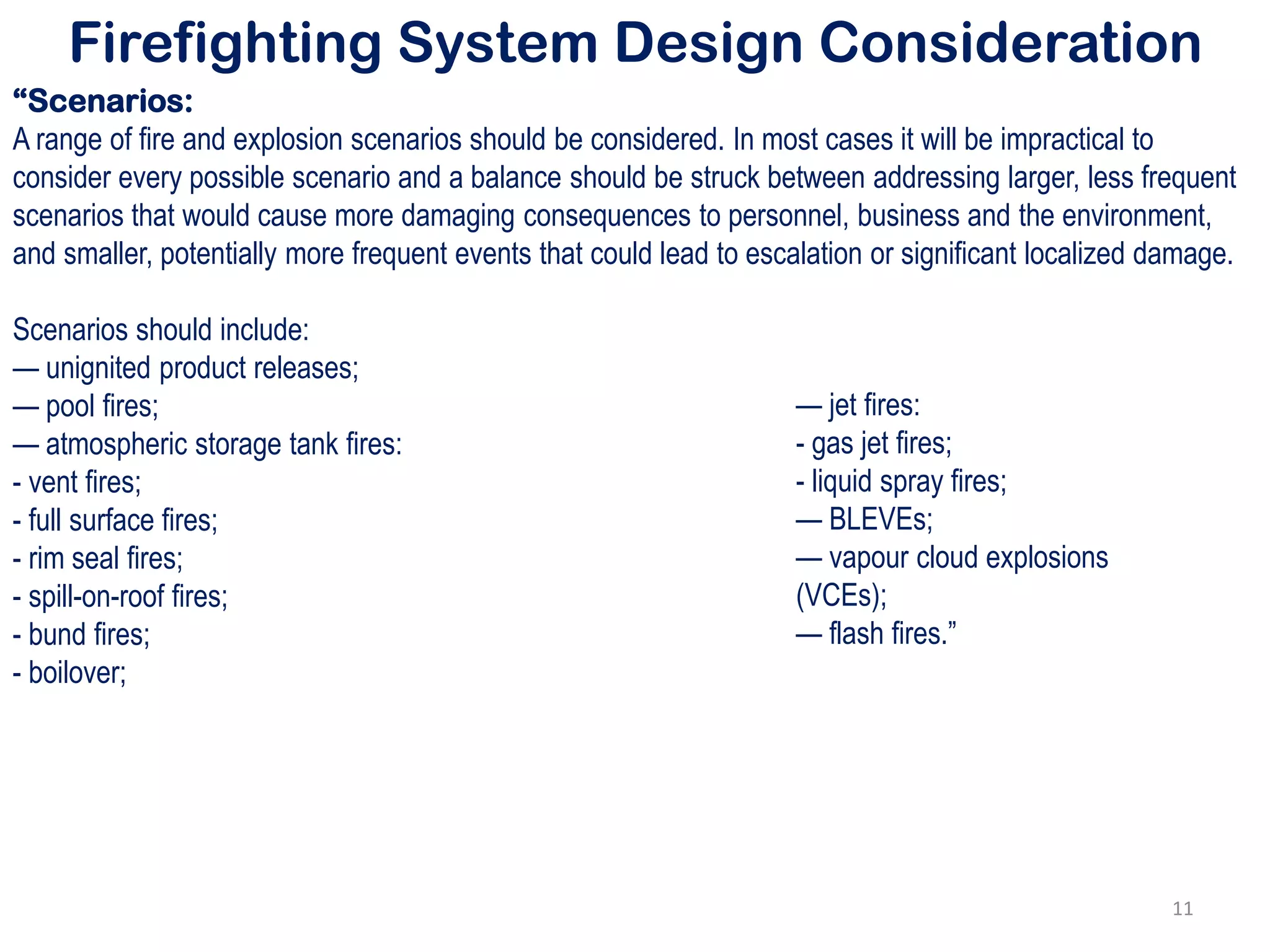

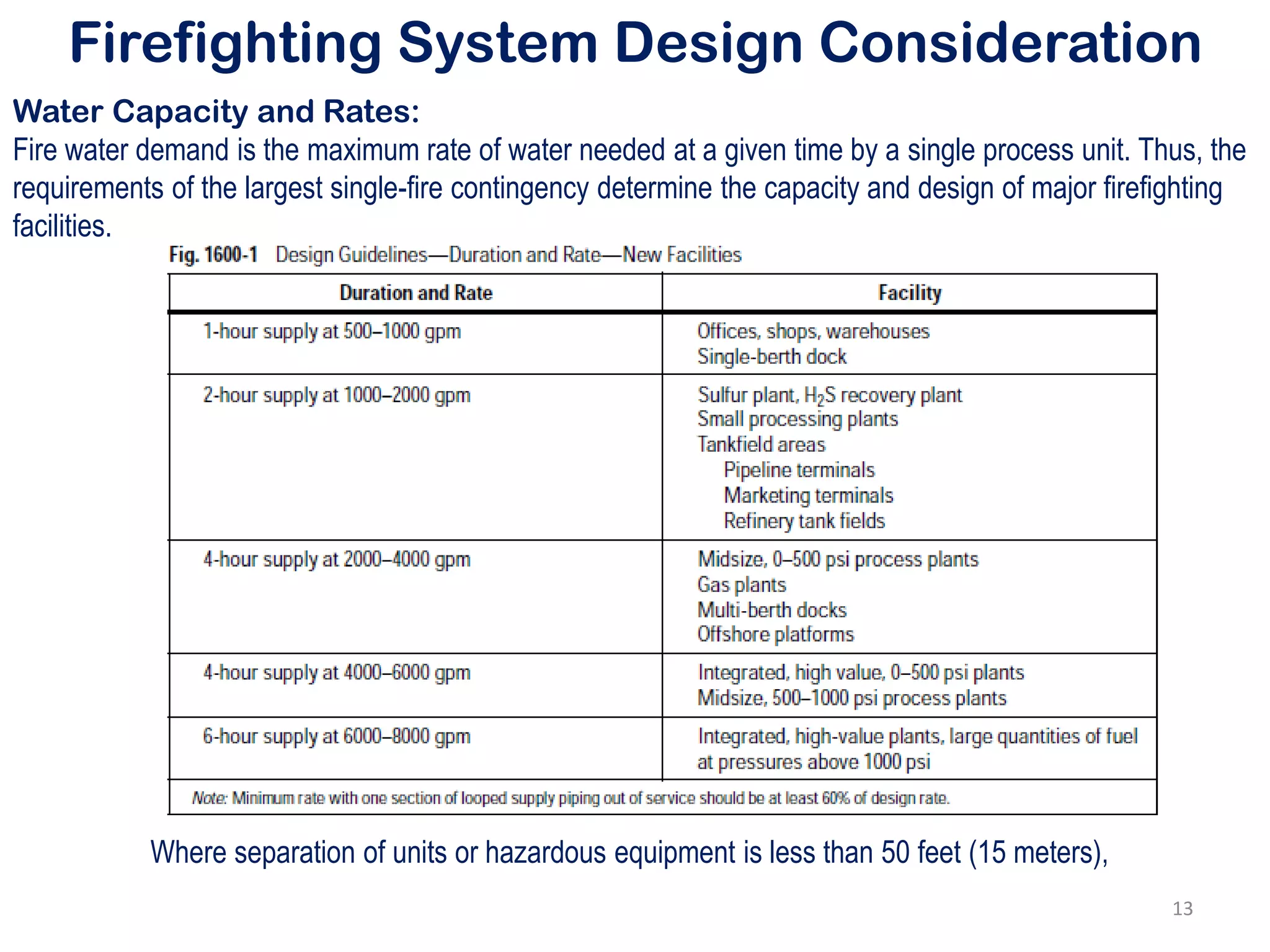

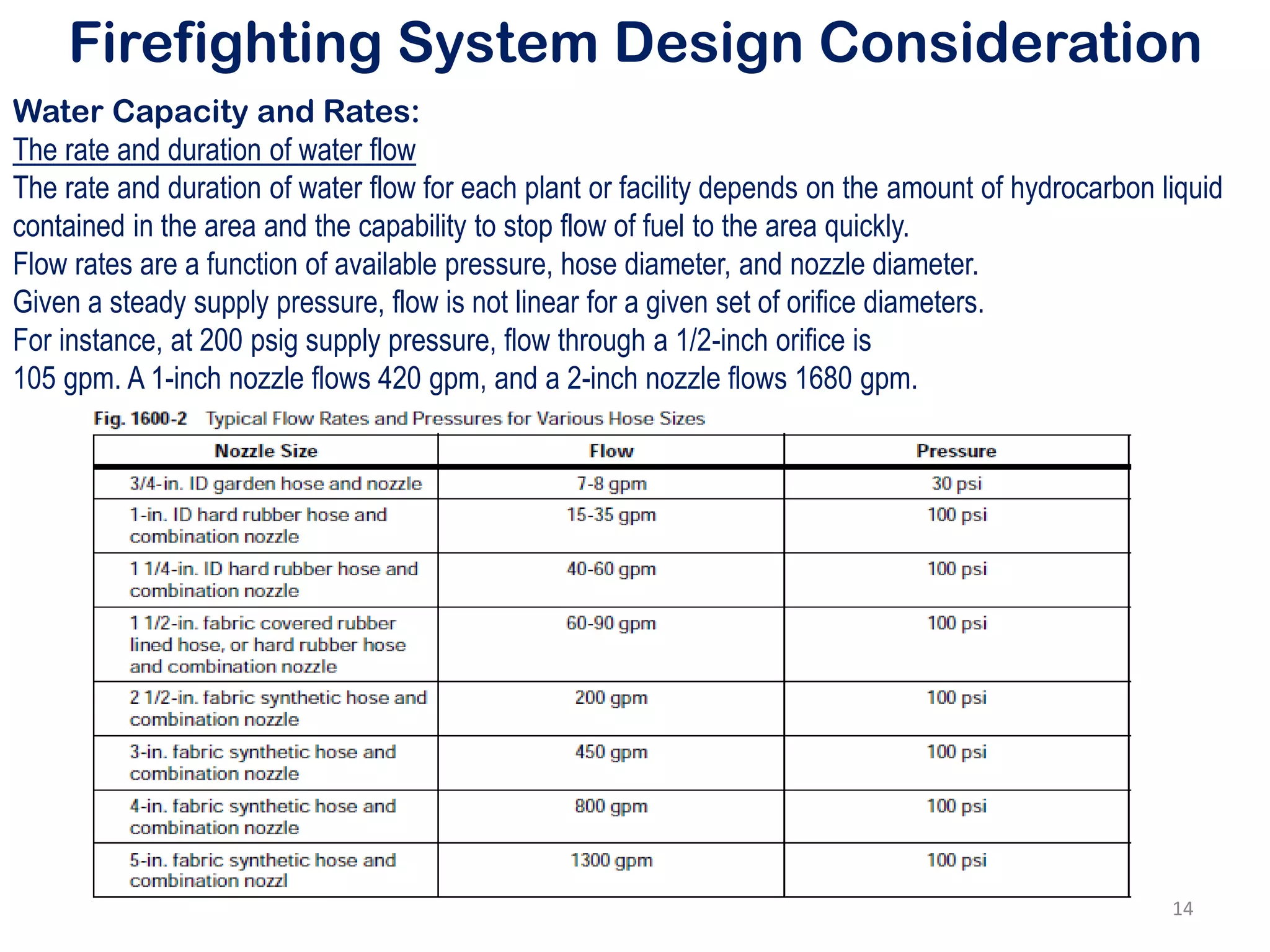

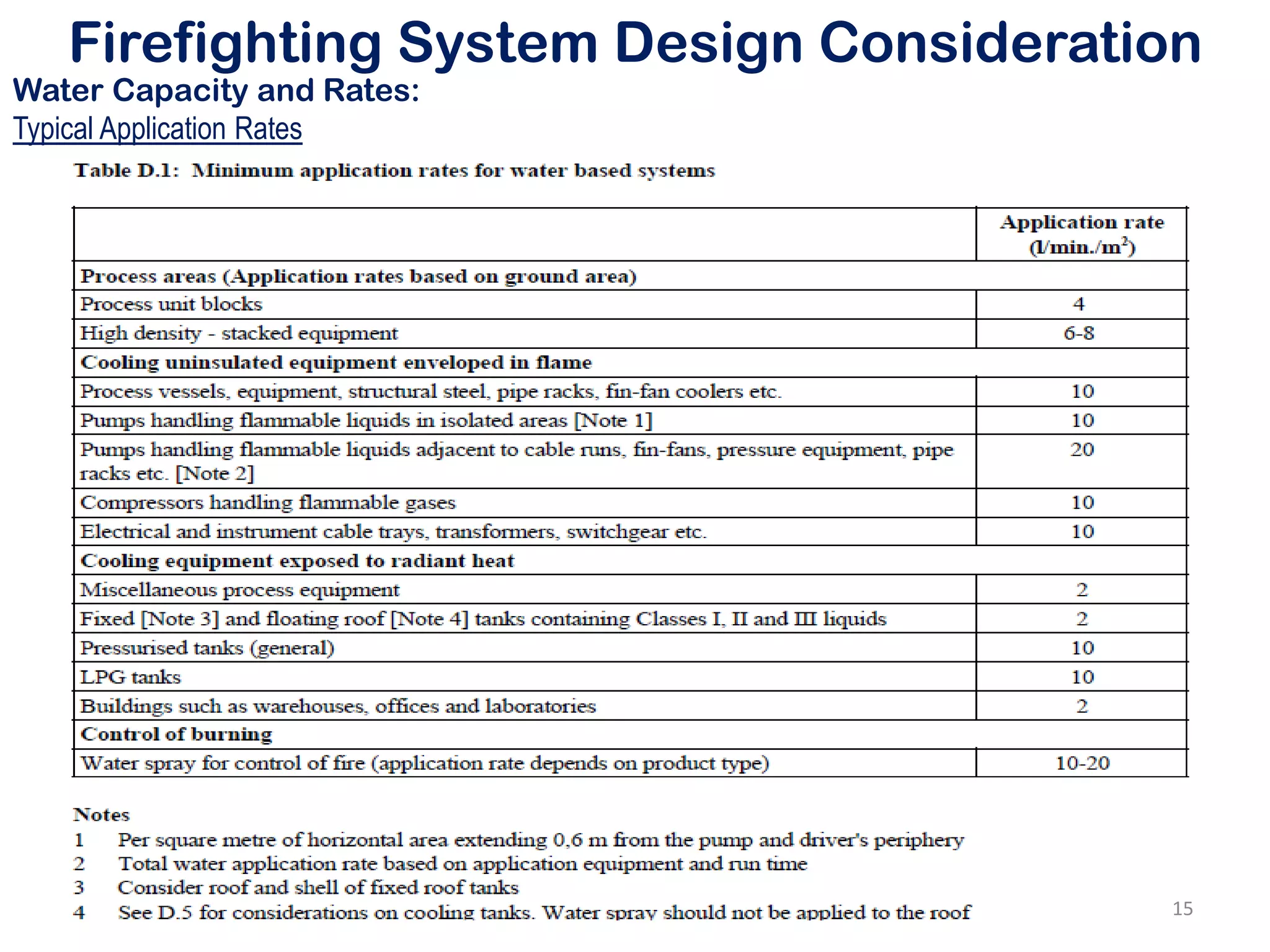

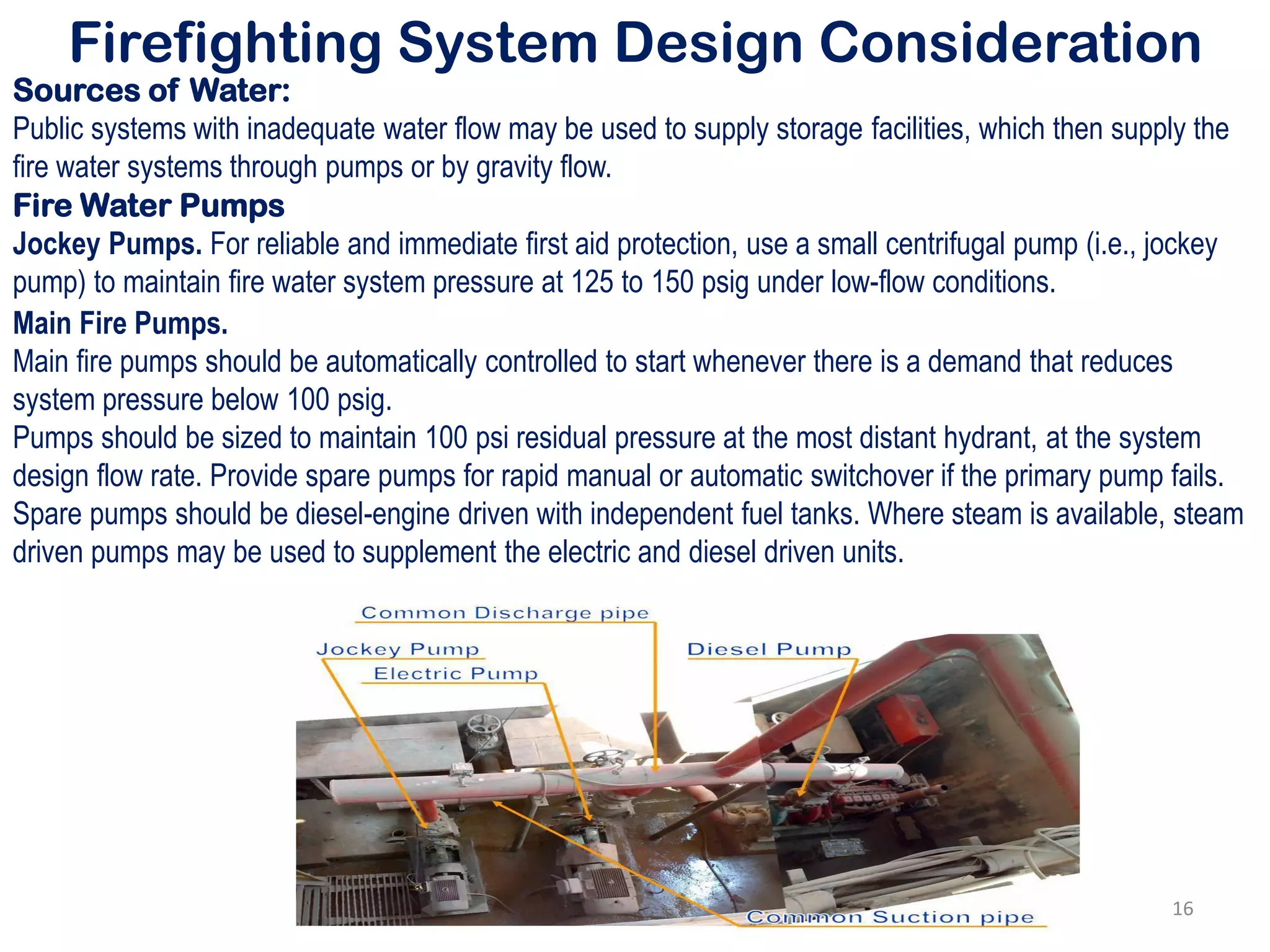

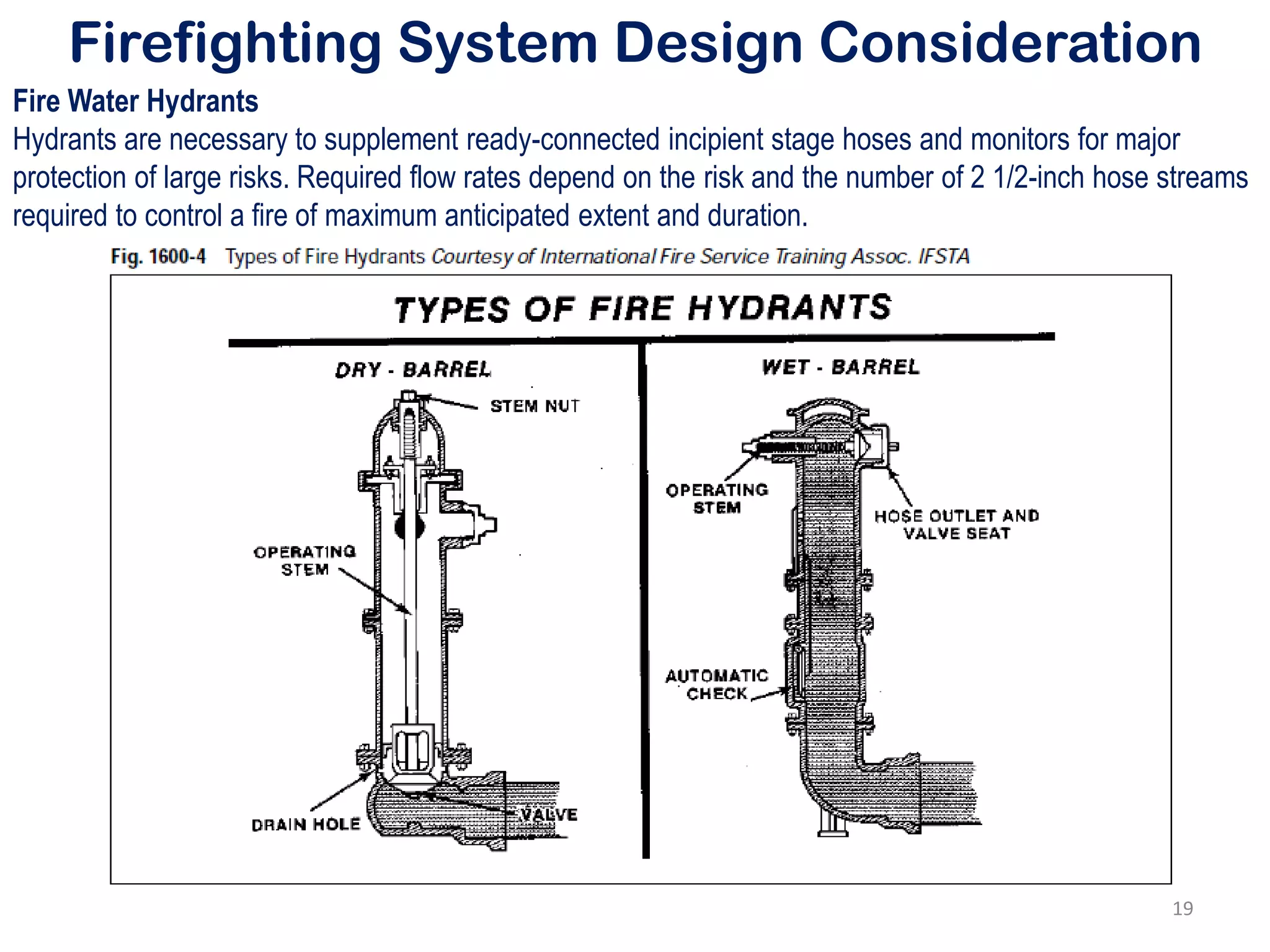

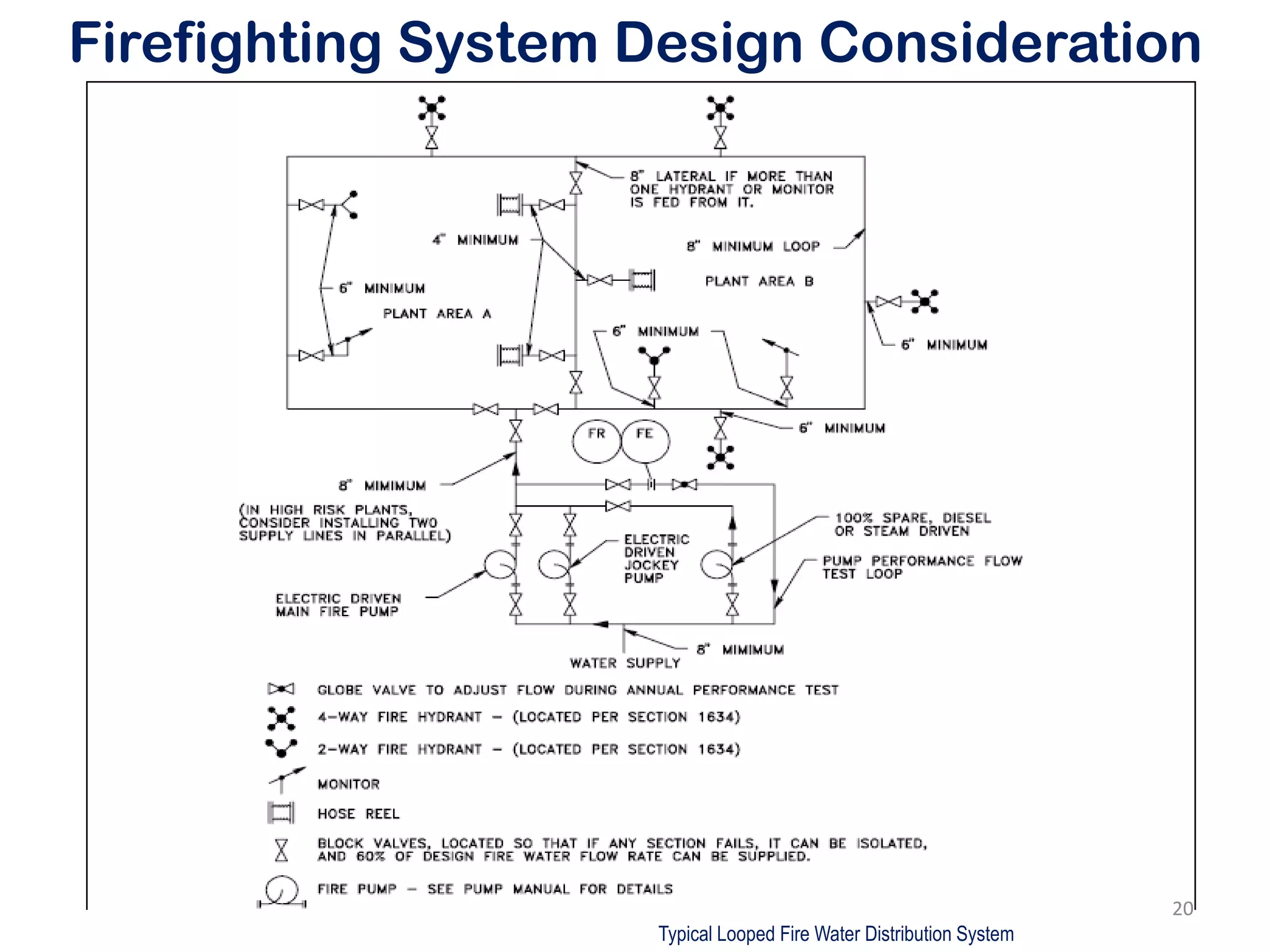

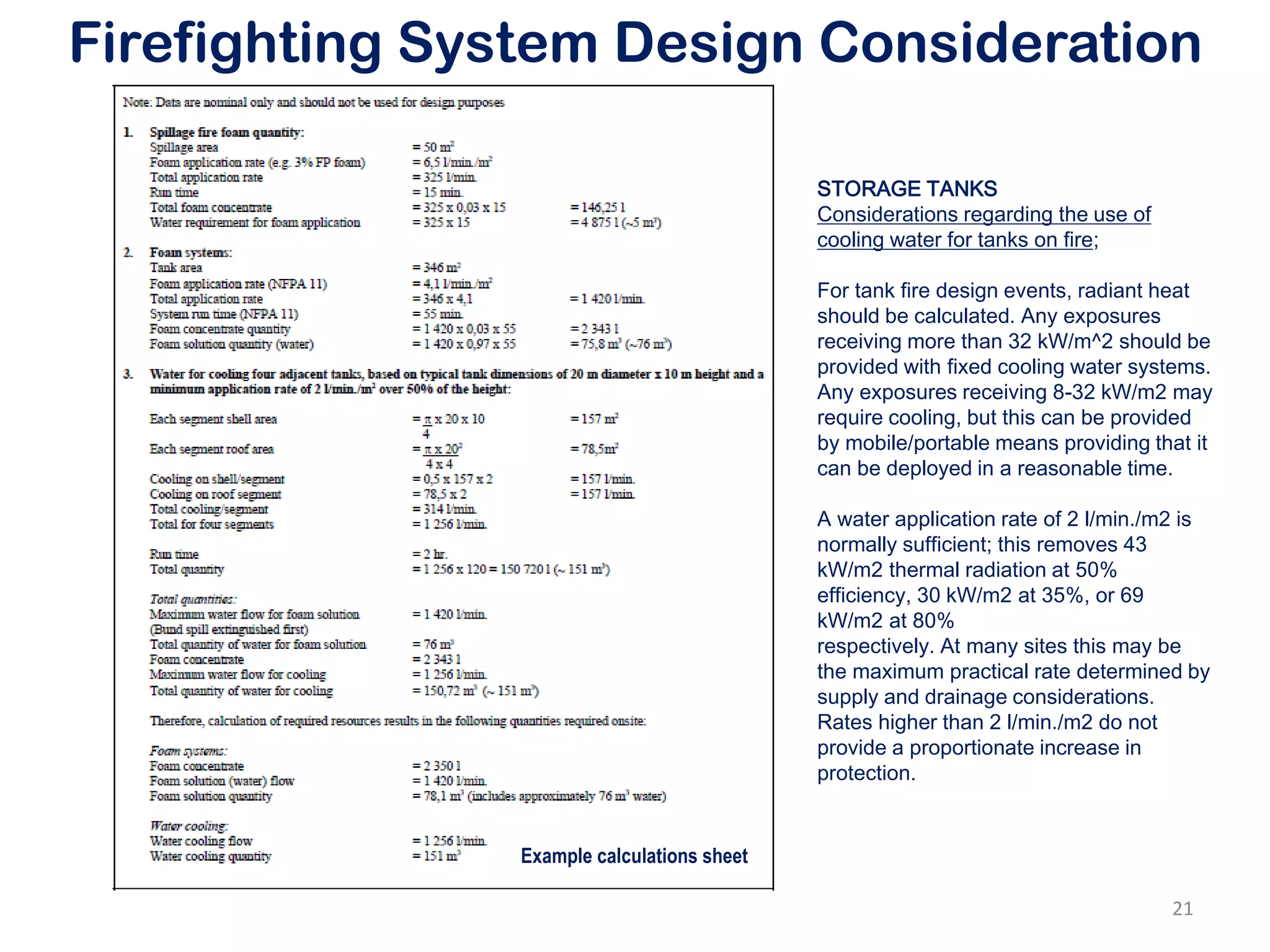

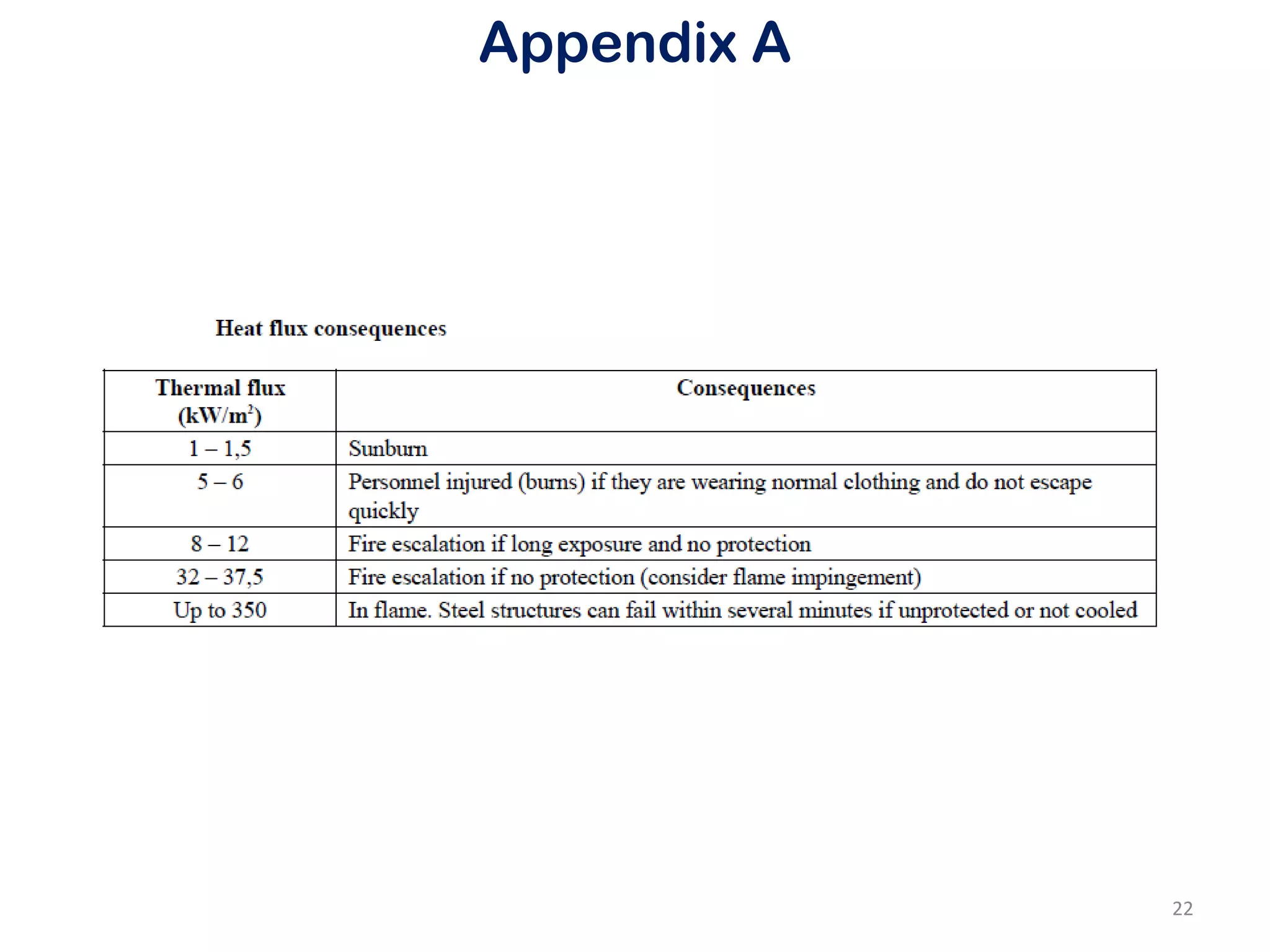

This document provides information on fire network design, including definitions of fire terms, classes of fire, extinguishing methods and agents, passive and active fire protection systems, and considerations for firefighting system design. It discusses water capacity and rates, sources of water, fire pumps, and piping design for firewater distribution systems. The key aspects covered are fire protection philosophy, sizing systems based on the largest single fire scenario, and maintaining adequate water pressure and flow rates throughout the network.