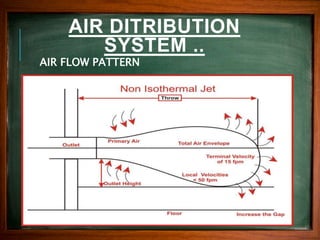

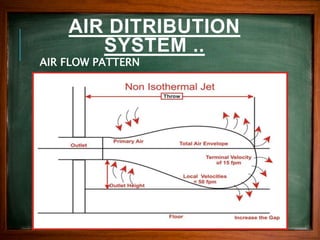

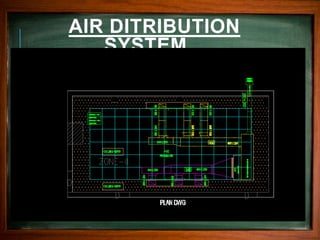

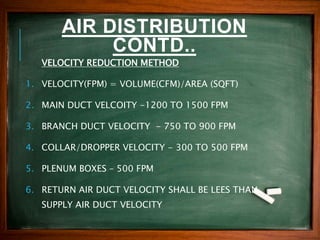

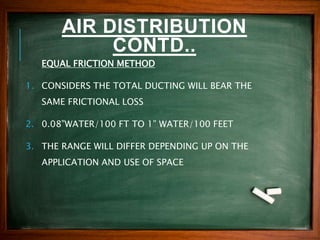

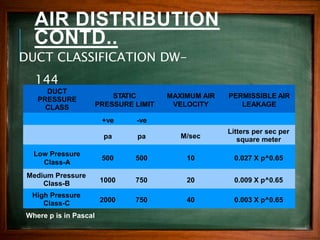

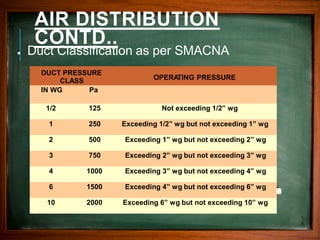

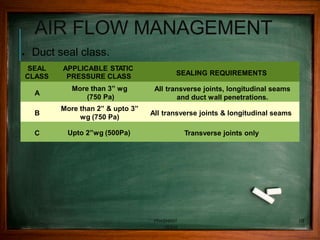

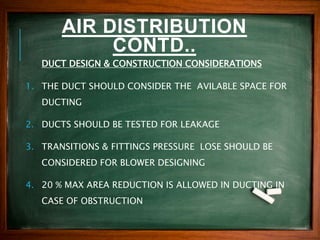

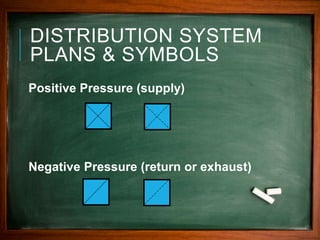

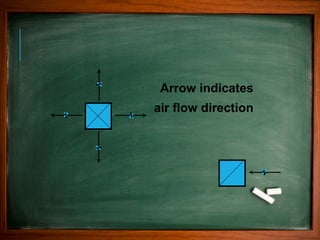

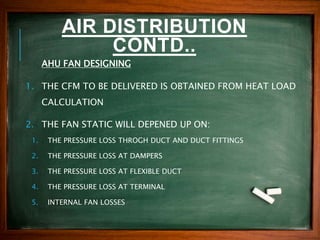

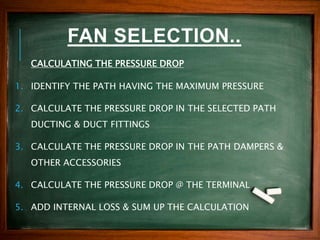

This document discusses fundamentals of air distribution systems including duct materials, shapes, sizing methods, and design considerations. It covers topics such as duct pressure classifications, sealing requirements, outlet selection factors, and fan sizing calculations. The key points are that ducts distribute air through a building, duct materials include galvanized iron and aluminum, and fan selection involves calculating pressure drops through ducts, dampers, and terminals to determine required static pressure.