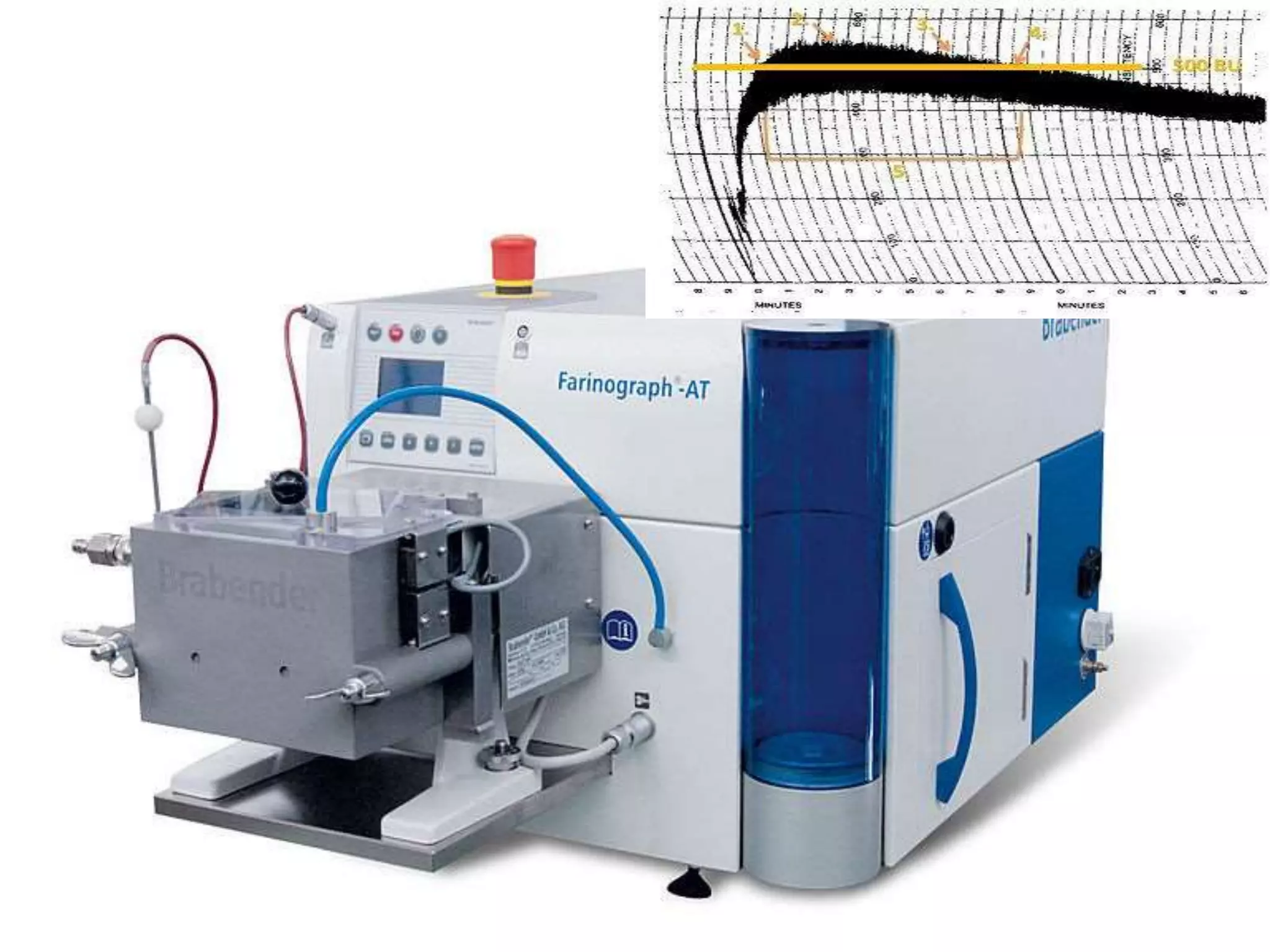

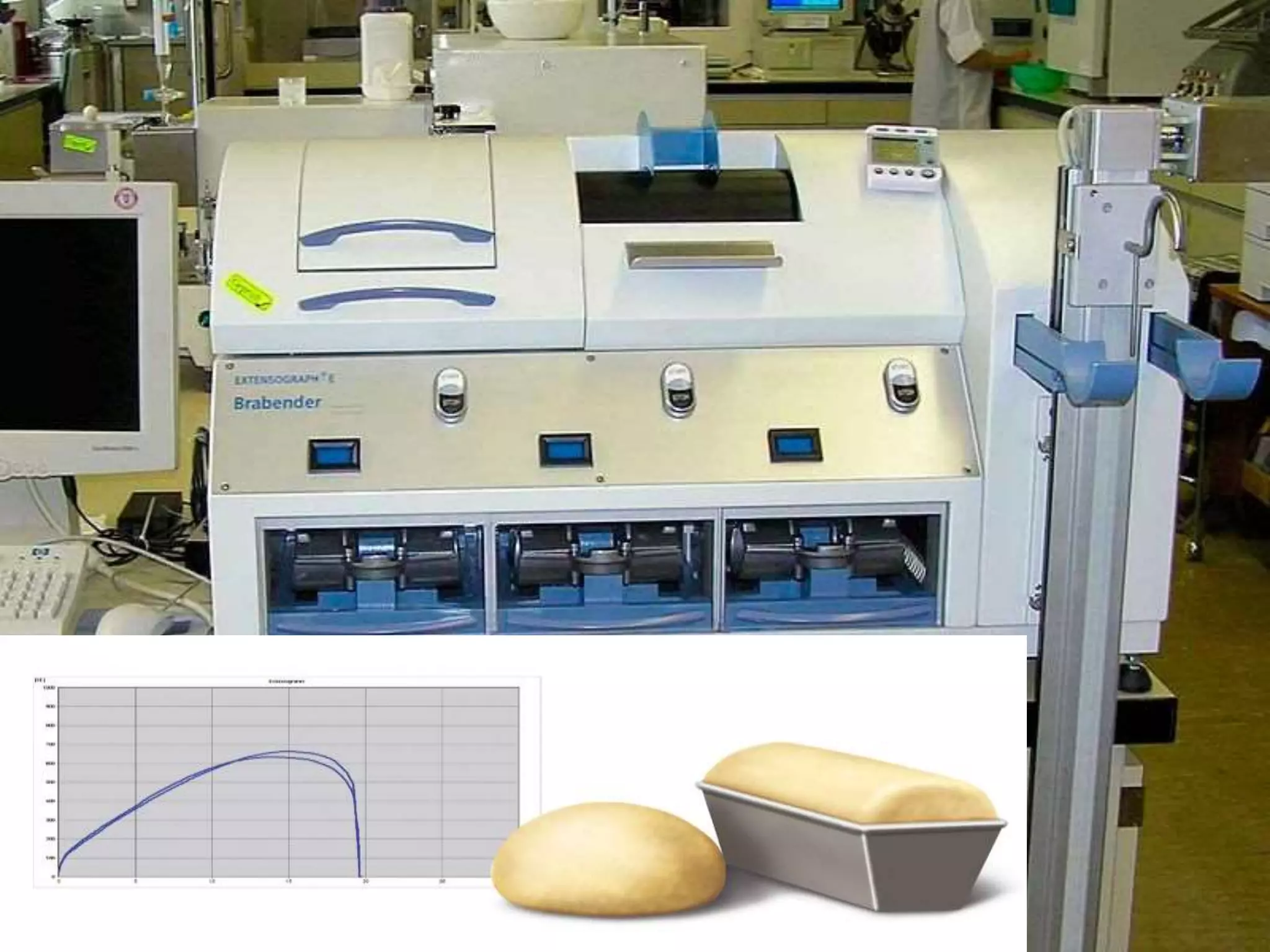

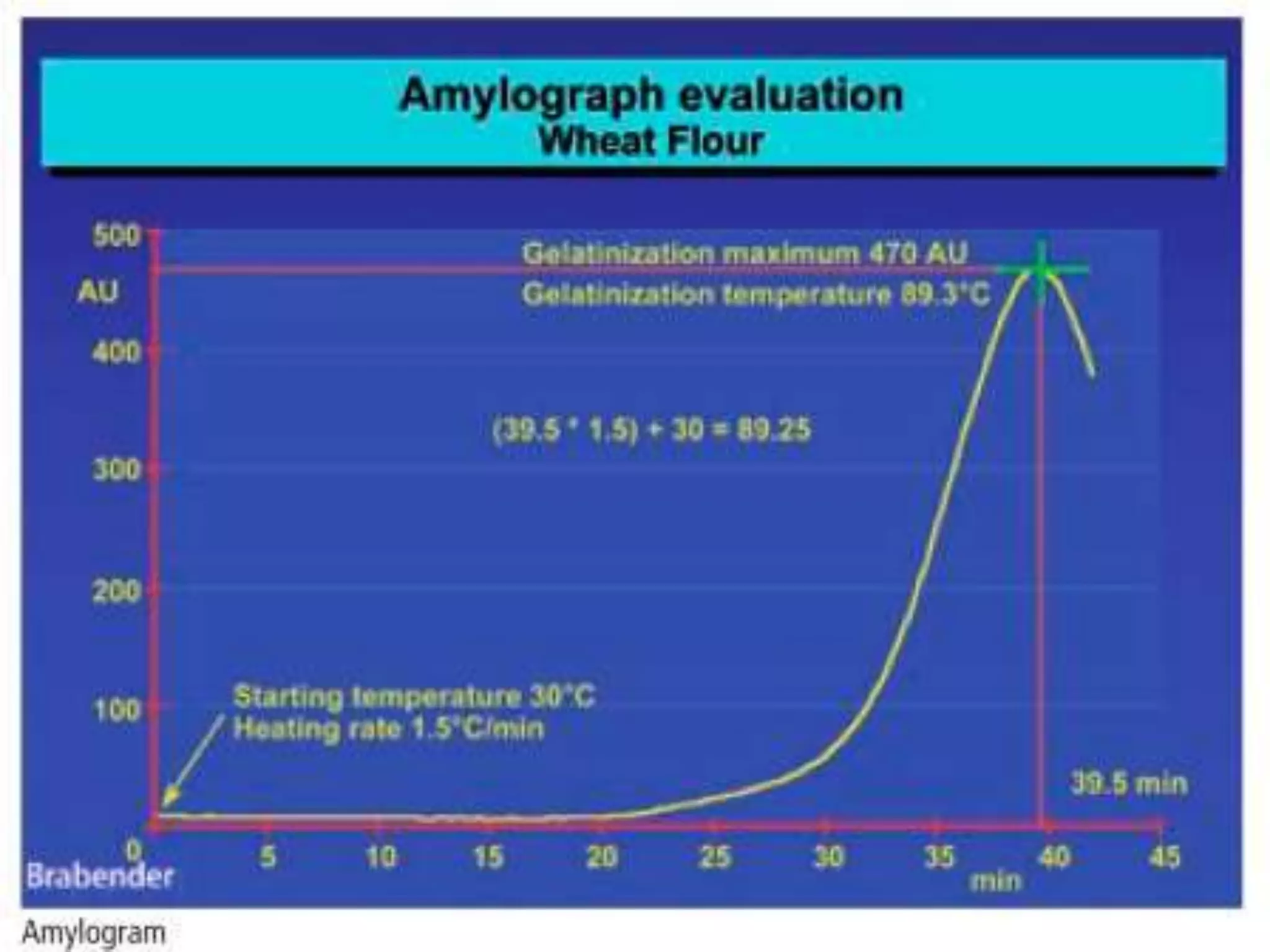

This document discusses dough rheology and various equipment used to analyze dough properties. It defines dough as a wet mass developed by mixing wheat flour, water, and other ingredients. Dough undergoes viscosity changes during mixing as it develops elastic and extensible characteristics. Equipment described includes the farinograph, extensograph, alveograph, mixograph, amylograph, and rapid visco analyzer. These tools measure properties like water absorption, viscosity, elasticity, and strength to evaluate dough development and quality.