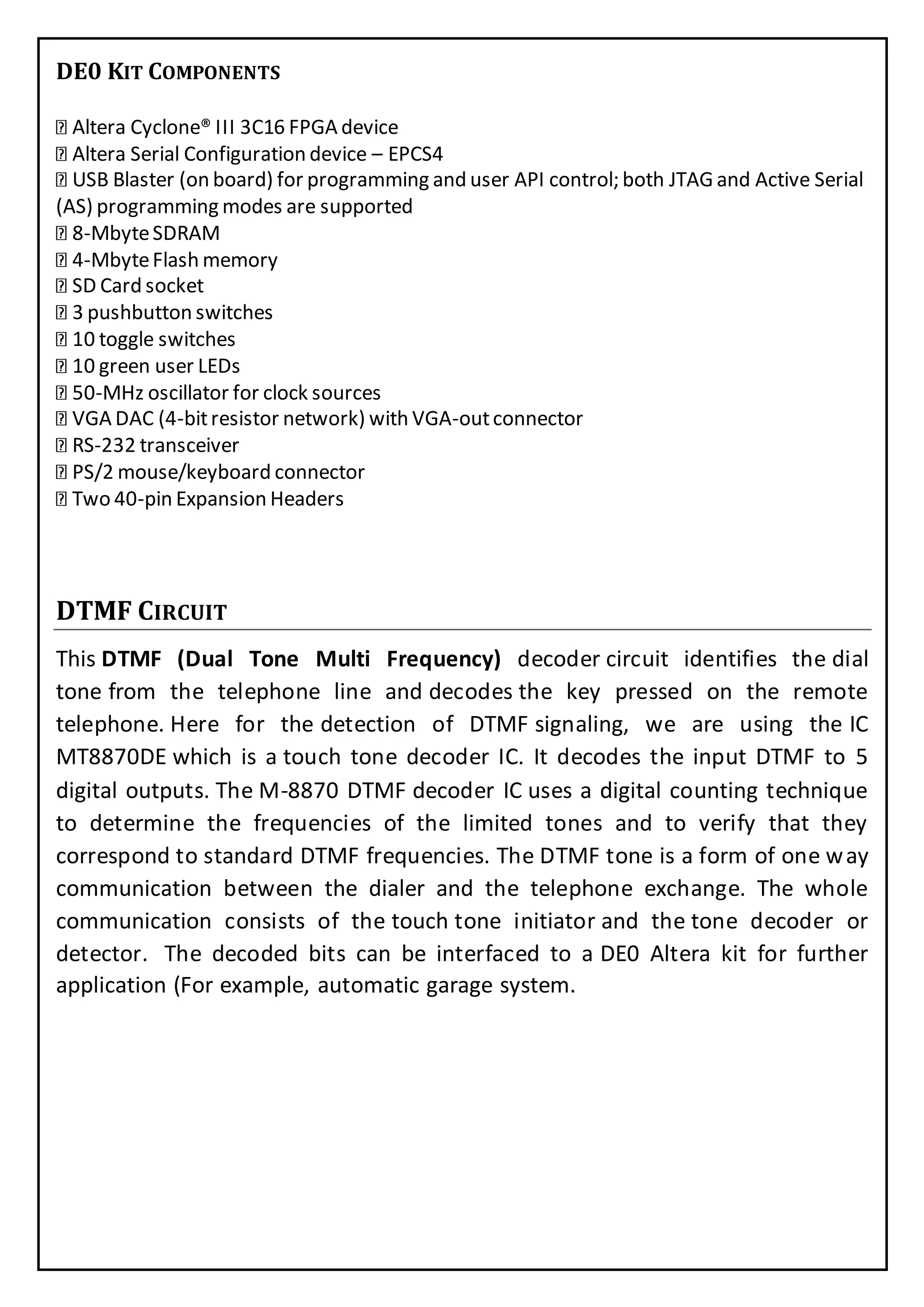

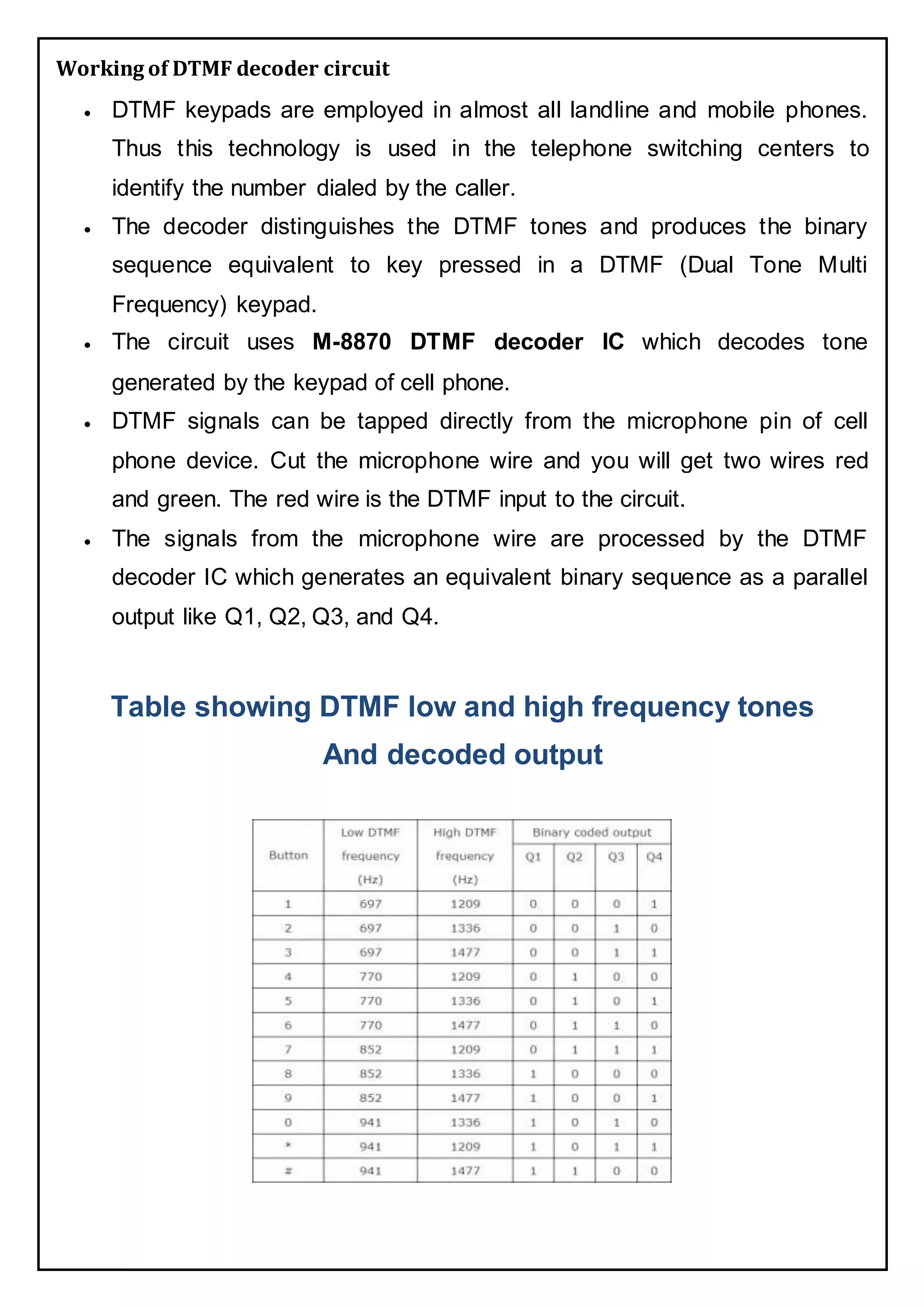

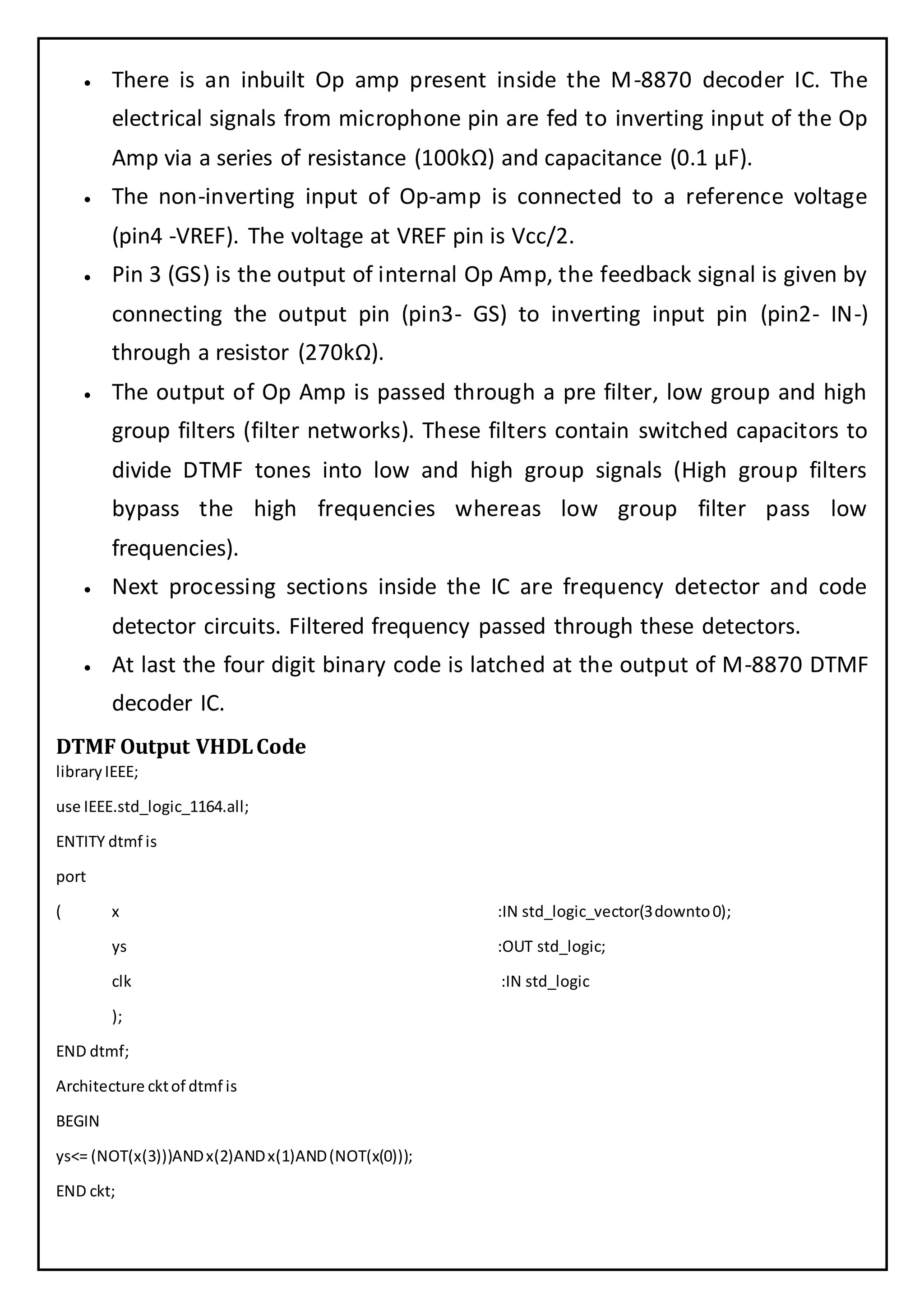

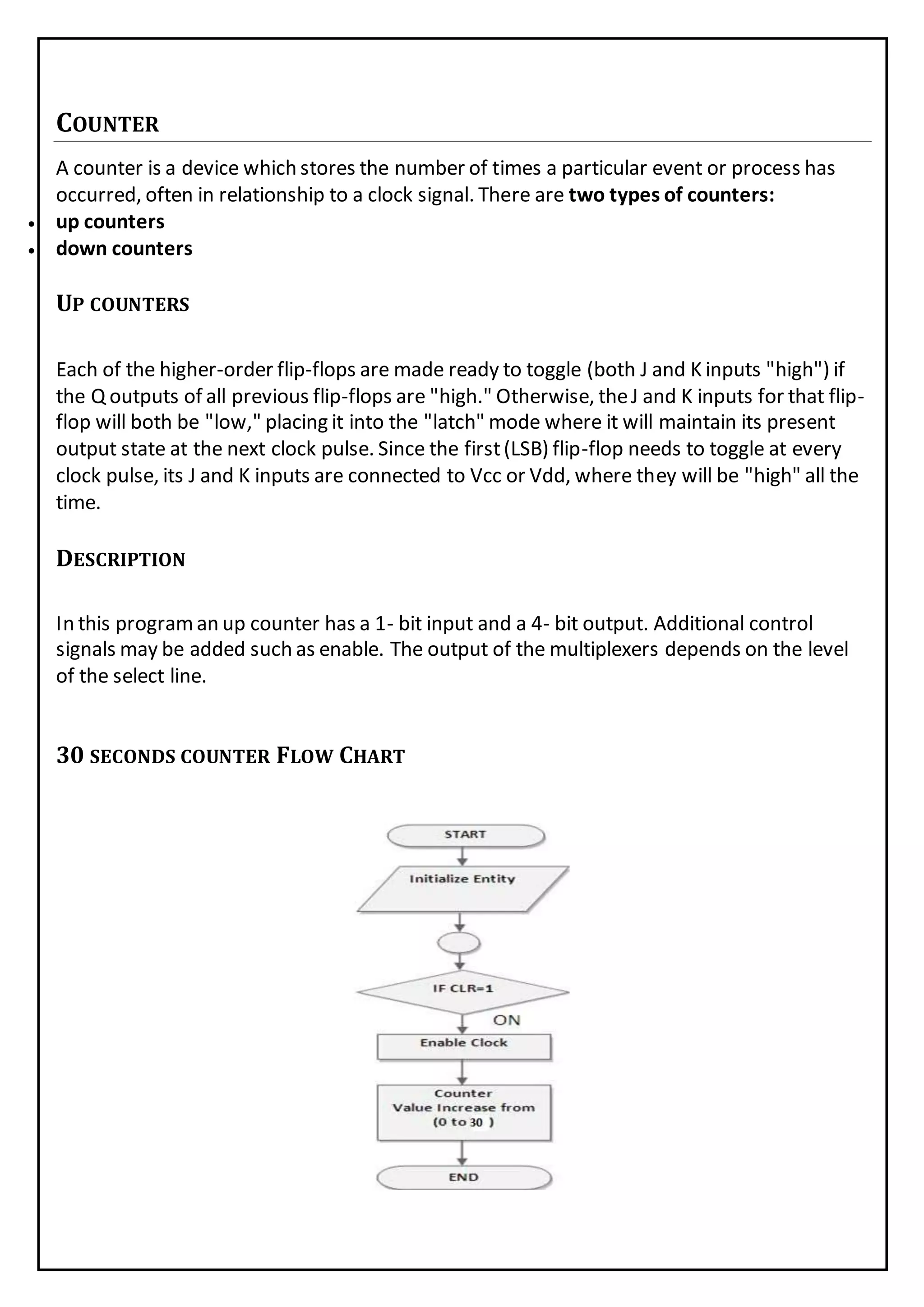

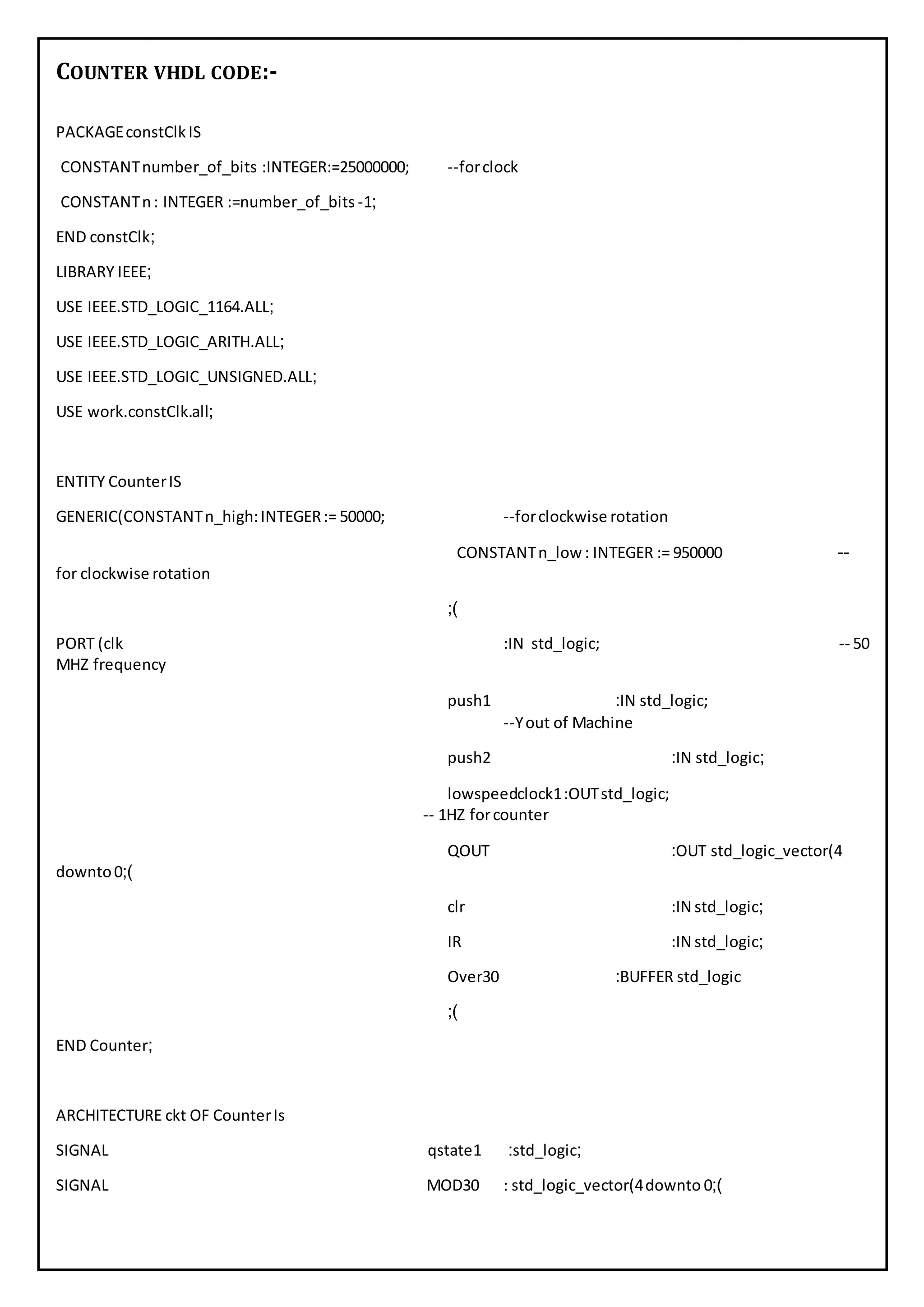

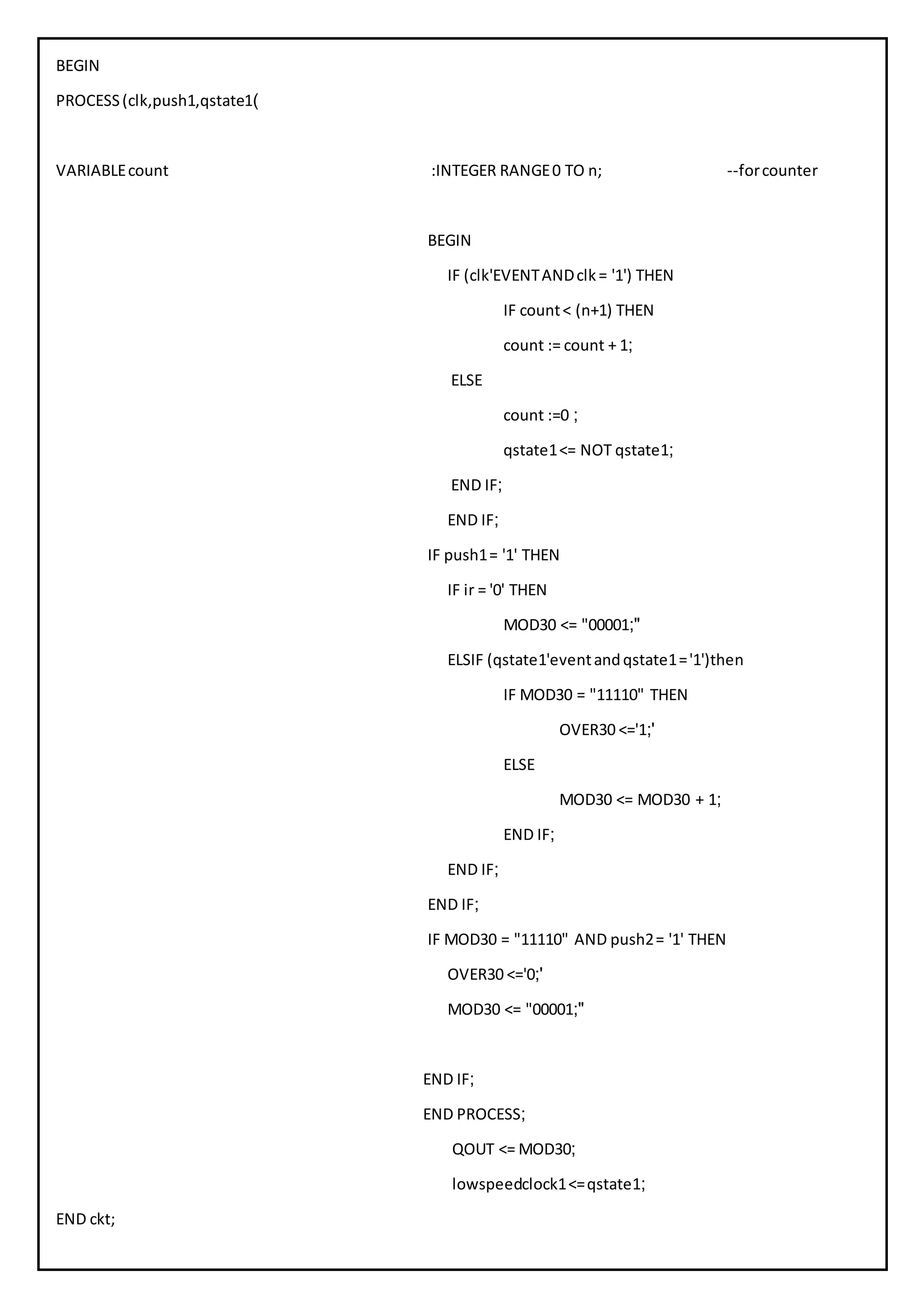

The document describes an automatic garage system that uses a VHDL programming language. It uses a DTMF circuit to receive signals from a cell phone and control servo motors to open and close the garage door. An IR sensor is used as input to a 30-second counter timer to close the door automatically after a car enters. The system utilizes components like a DE0 Altera kit, DTMF decoder, servo motors, IR sensor, and counters in VHDL code to control the opening and closing of the garage door remotely via a cell phone.