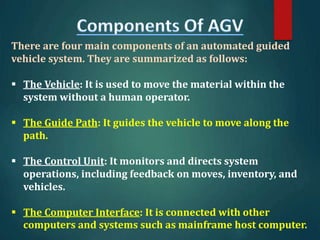

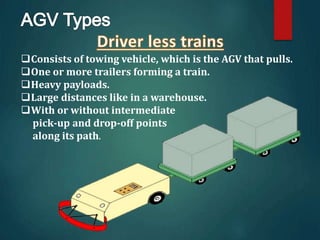

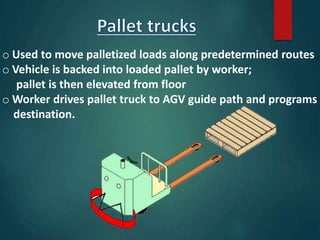

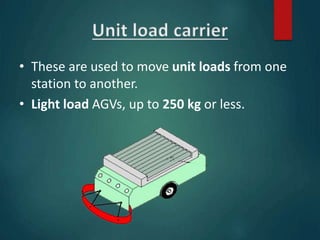

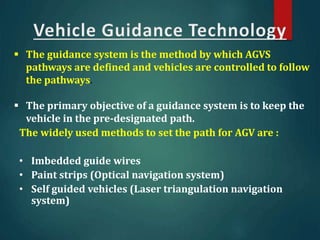

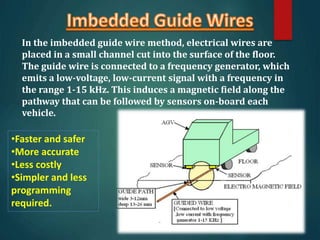

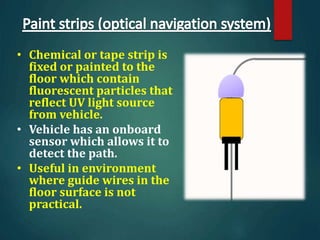

The document discusses automated guided vehicles (AGVs) which are used for material handling in manufacturing facilities. AGVs can move materials autonomously along predetermined routes with minimal human intervention. They have on-board batteries and controls to navigate pathways using embedded wires, painted lines, or lasers and sensors. AGVs improve productivity and safety by automating material transportation between different locations in a facility without requiring manual labor.