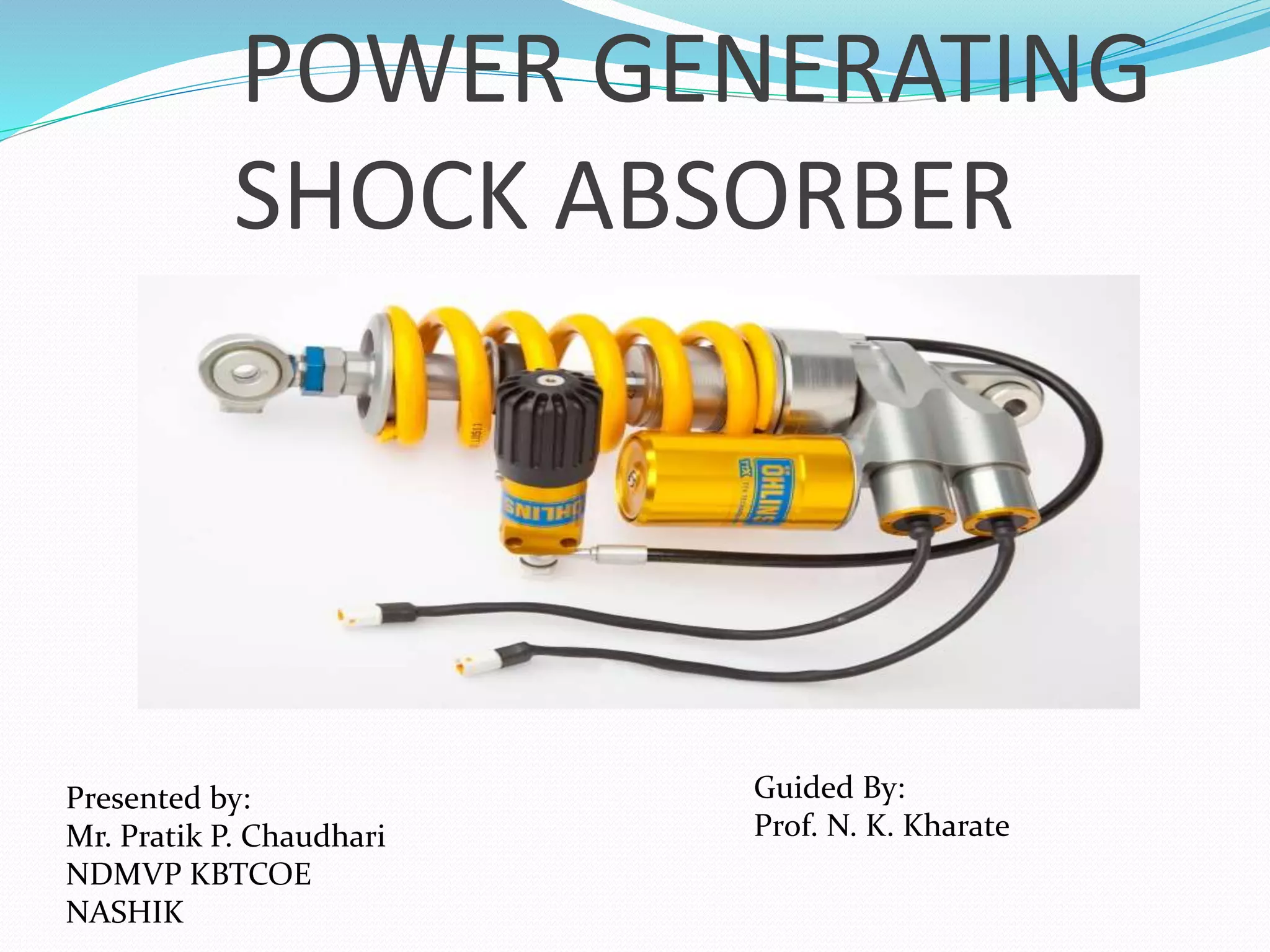

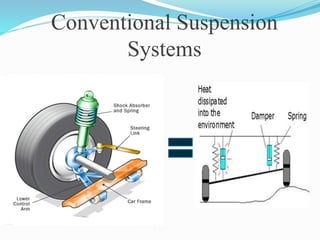

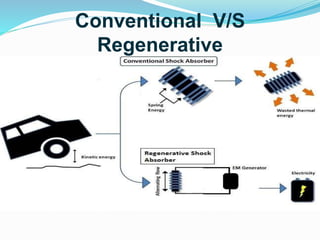

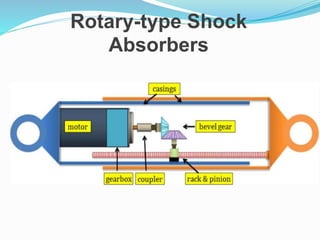

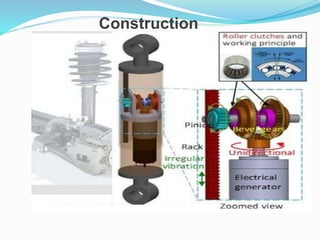

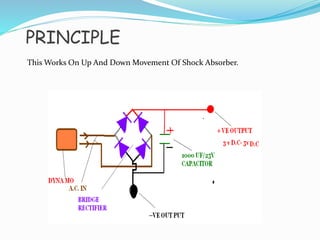

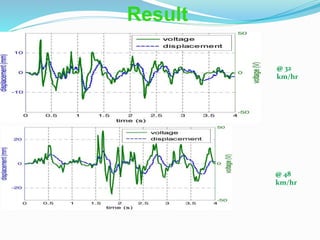

This document discusses power generating shock absorbers that can convert the up and down movement of a vehicle's suspension into electricity. It describes two types of regenerative shock absorbers - linear and rotary - and explains their construction and operating principles. Road tests on a Chevrolet Suburban found the system generated electricity without significantly affecting vehicle momentum. While costly and complex, regenerative shock absorbers could improve fuel efficiency by 2-10% depending on road conditions and allow for energy recovery typically not possible with conventional braking systems. Further research aims to optimize design and test effectiveness in additional vehicle types.