Embed presentation

Download to read offline

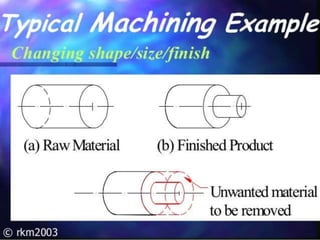

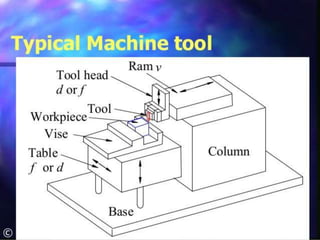

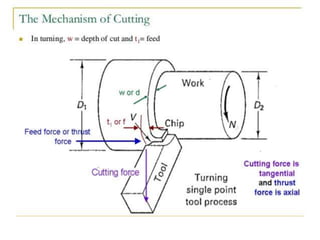

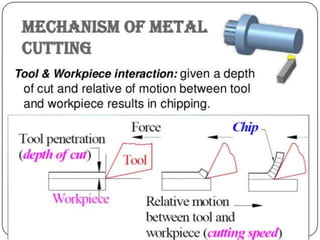

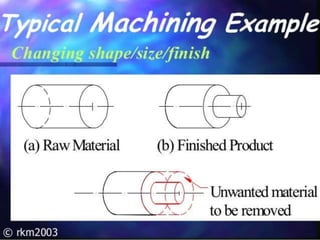

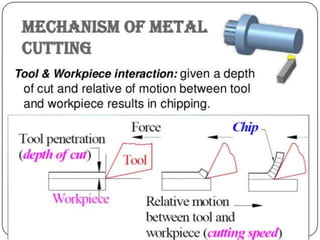

Machine cutting tools are machines used to shape metal and other rigid materials by cutting, boring, grinding, shearing or deforming. They employ cutting tools made of materials harder than what is being cut to withstand heat and have a specific geometry. An ideal cutting tool is highly temperature stable, resistant to wear and tear, impact and chemically inert. Machine cutting tools are used to remove unwanted material and achieve a desired final shape, size and surface finish of a product in an economical way, though they can result in material loss and require skilled operation.