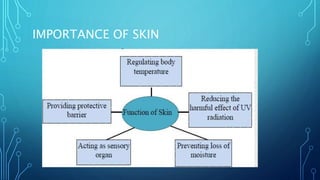

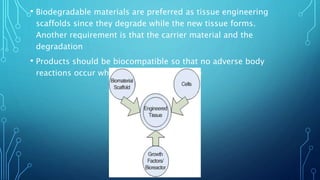

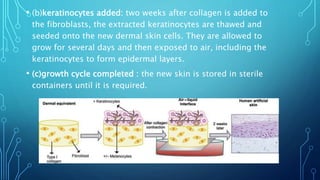

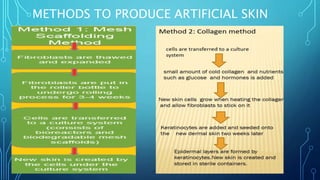

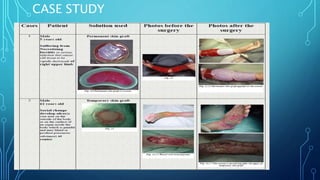

The document discusses tissue engineering and artificial skin. It describes how the first artificial skin was invented using collagen fibers and sugar molecules to form a porous material resembling skin. It also outlines the structure of human skin and importance of skin. The key developments in artificial skin are explained, including using a small skin sample to grow enough skin to cover the body in 3 weeks. The document details the methods used to produce artificial skin, including using mesh scaffolds or collagen gels with fibroblasts and keratinocytes to form layers resembling skin. Future developments aim to produce fully functional lab-grown skin grafts.