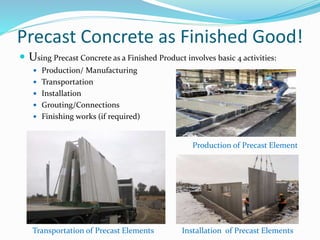

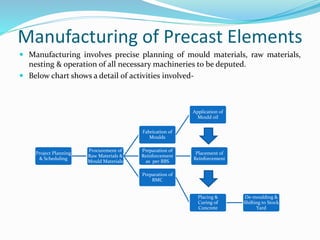

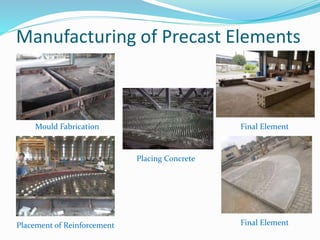

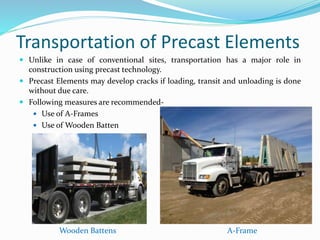

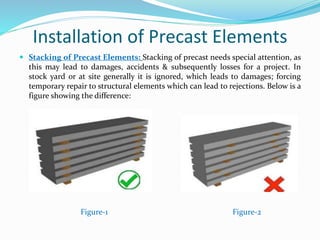

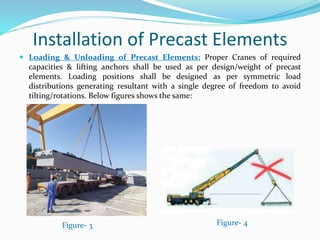

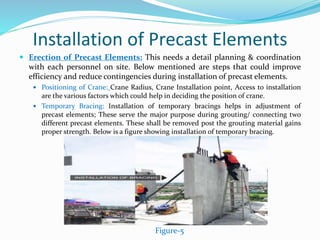

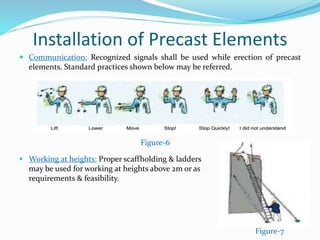

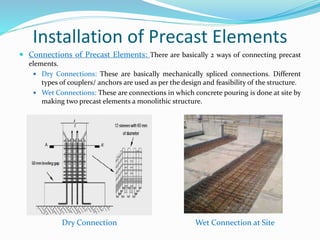

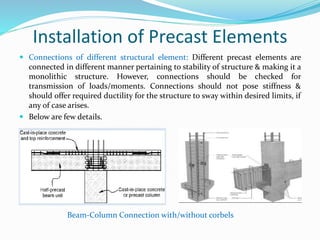

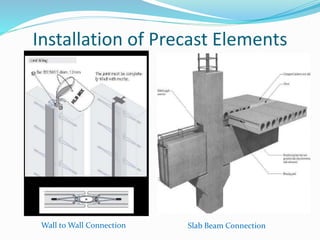

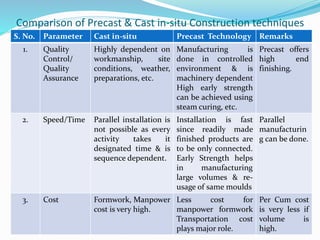

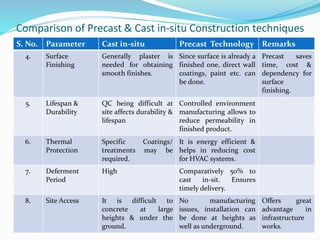

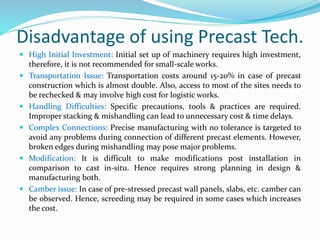

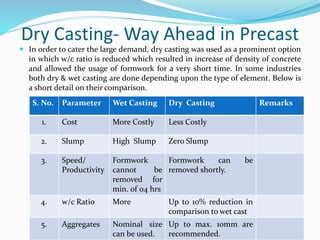

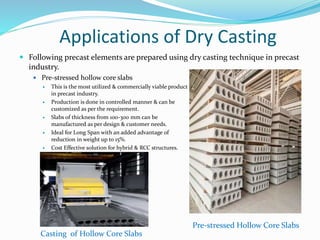

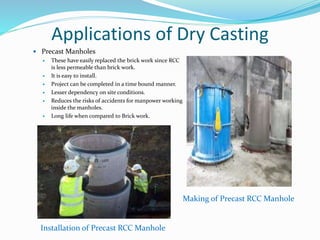

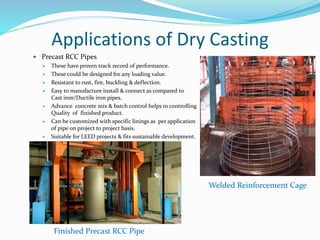

The document outlines key principles and processes in the precast concrete manufacturing industry, emphasizing the importance of marketing, materials, manpower, machinery, and manufacturing processes. It details the manufacturing and installation phases of precast elements, highlighting challenges such as transportation, connections, and the advantages of controlled environment production. Additionally, it compares precast technology with traditional cast in-situ methods, noting benefits like quality control, efficiency, and cost implications.