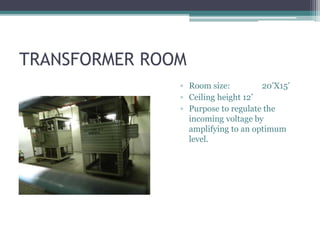

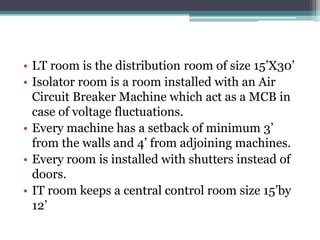

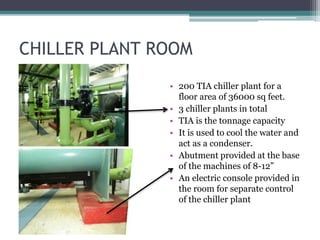

This document outlines the key electrical, HVAC, firefighting, water, and sanitation services for a commercial building located in Centra Mall. It describes the components and specifications of the transformer room, voltage control room, LT room, isolator room, IT room, chiller plant room, air handling units, pump room, fire exits and hydrants, water tanks, and drainage system. The building services were designed and installed by Spectral Service Consultants to meet the needs of the 36,000 square foot commercial building.