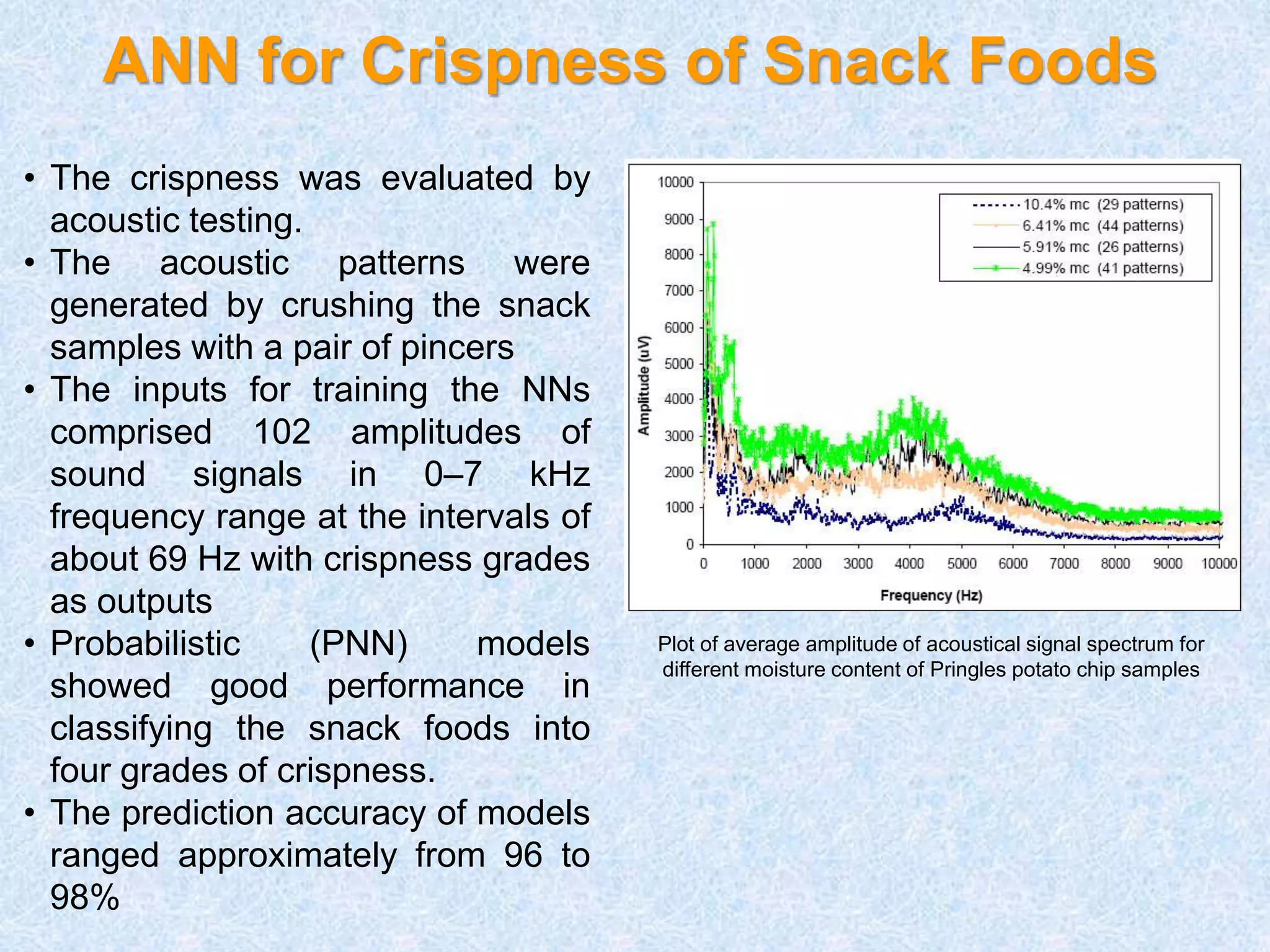

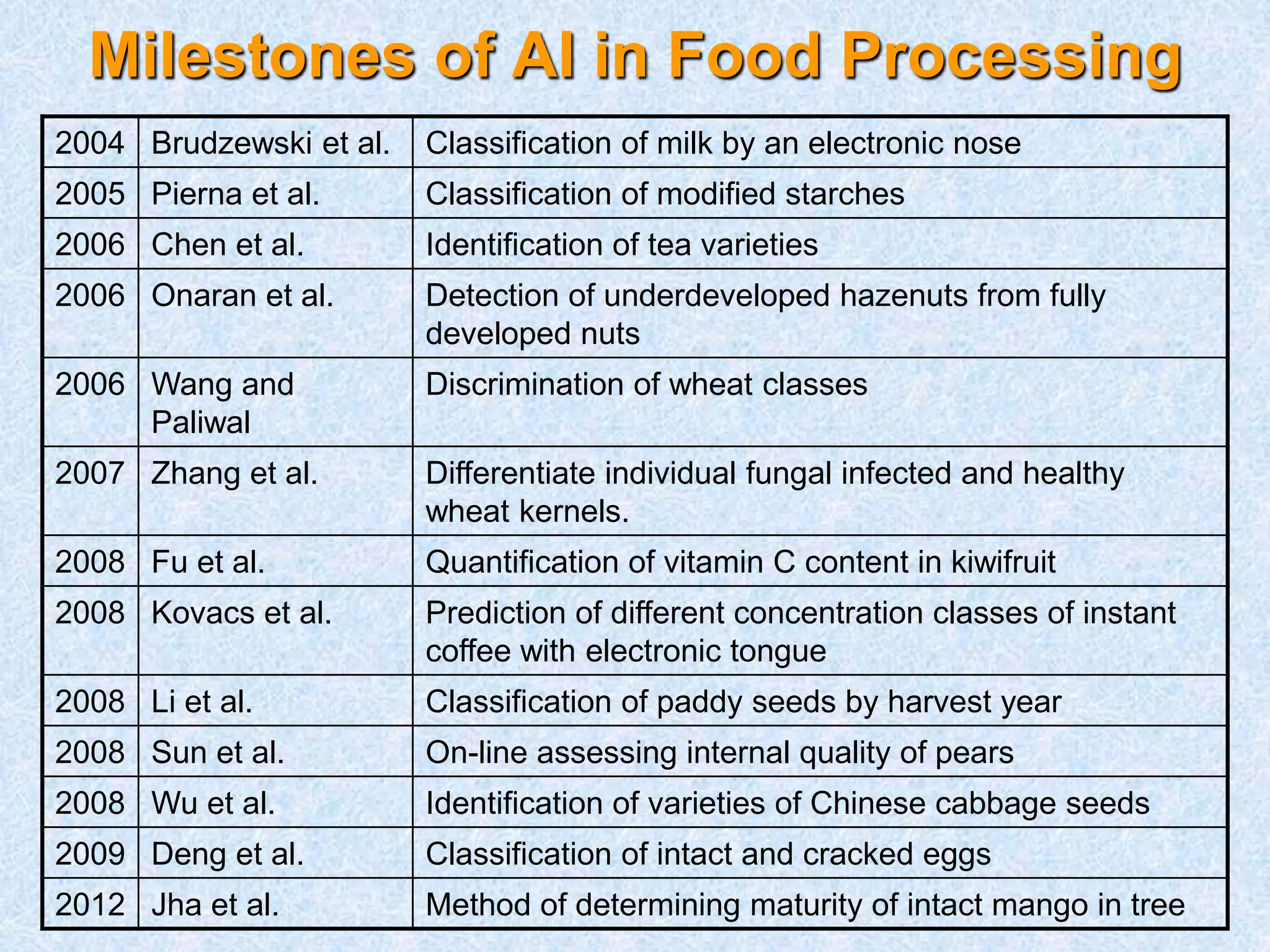

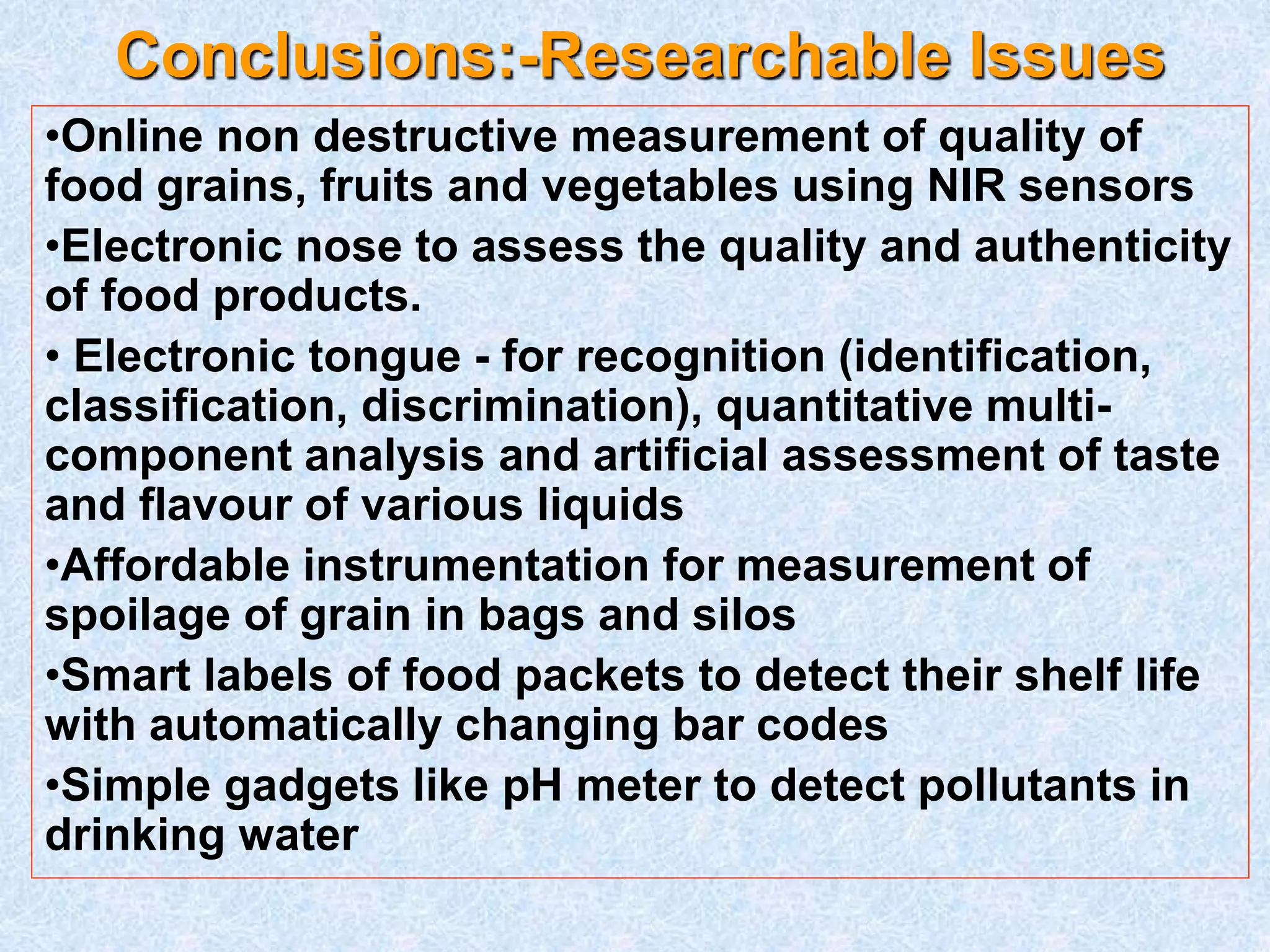

This document discusses the use of artificial intelligence in the food processing sector in India. It notes that the food processing industry in India is large but that quality and safety issues are a priority for improvement. It then describes how various artificial intelligence techniques, including fuzzy logic, neural networks, genetic algorithms, and others can be applied to complex food processing control problems to model non-linear systems with imperfect data. Several examples are provided of applications of AI for tasks like detecting plant diseases, evaluating food crispness, detecting defects in fruits, and identifying weeds. The document concludes by outlining some research areas where AI could further improve food quality measurement and monitoring.