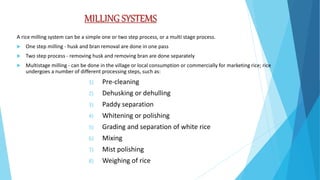

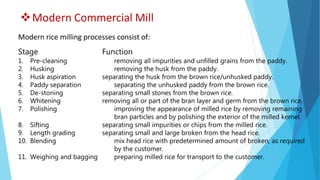

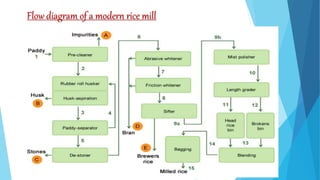

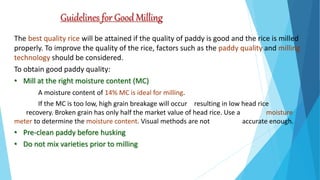

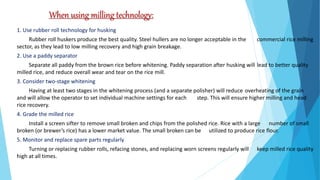

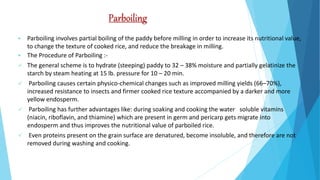

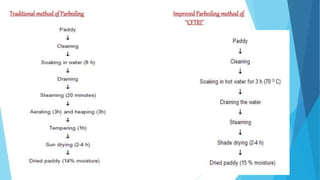

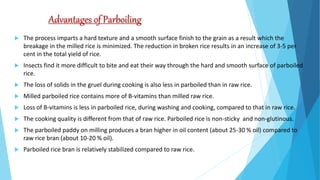

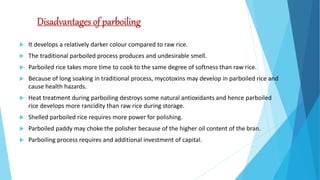

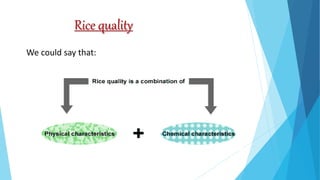

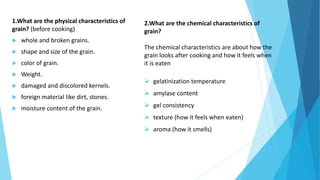

The document provides an overview of rice, including its classification, milling processes, parboiling techniques, and quality parameters. It distinguishes between village and commercial milling systems, outlining the objectives and types of commercial mills. Additionally, it discusses the advantages and disadvantages of parboiling, as well as the physical and chemical characteristics that define rice quality.