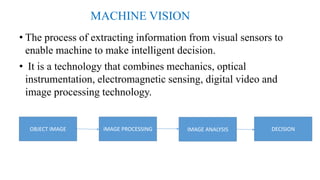

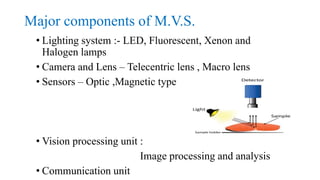

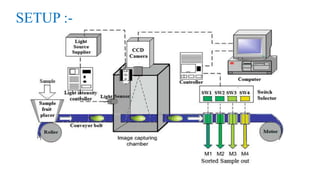

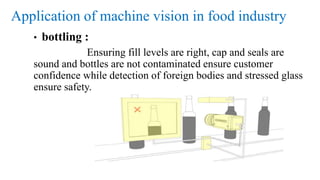

This document discusses the use of machine vision systems in the food industry. It begins by defining machine vision as using visual sensors and image processing to enable machines to make intelligent decisions. It then explains that machine vision provides an automated, non-destructive, and cost-effective way to assess quality factors like appearance, flavor, and texture. Major applications of machine vision in the food industry include quality control, harvesting, sorting and grading, packing, food safety checks, bottling verification, and labeling verification. The document concludes that machine vision systems can increase productivity, quality, and customer satisfaction while reducing costs.