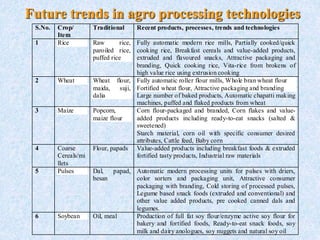

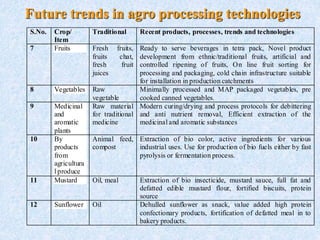

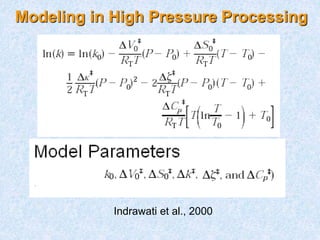

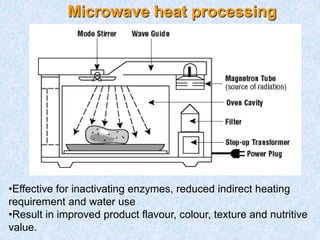

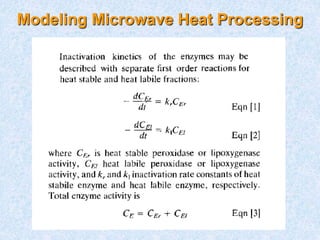

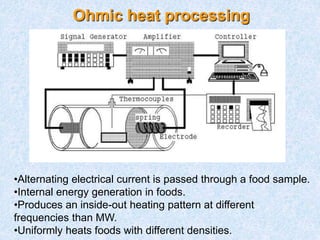

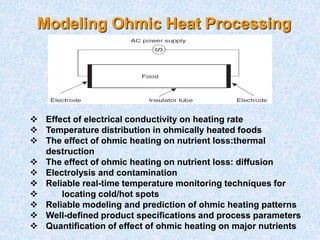

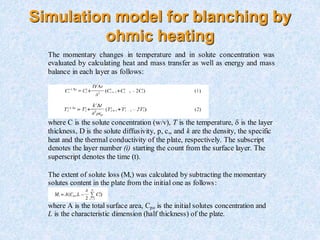

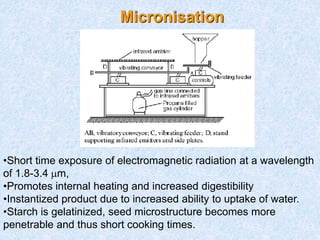

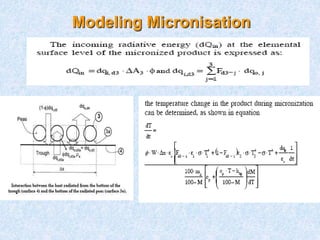

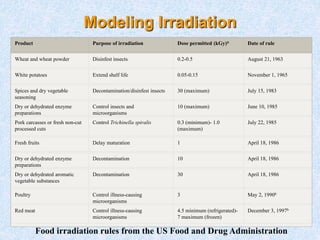

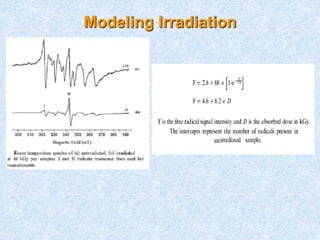

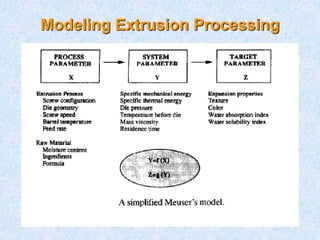

This document discusses the role of engineering principles and mathematical modeling in food processing technologies. It provides an overview of various traditional and recent food processing methods for crops like rice, wheat and fruits/vegetables. Emerging technologies discussed include high pressure processing, microwave heating, ohmic heating, irradiation and extrusion processing. The importance of modeling various aspects of these technologies is emphasized, such as bacterial inactivation kinetics under high pressure processing, temperature distribution during ohmic and microwave heating, nutrient loss during different thermal processing methods, and extrudate properties. Specific examples of mathematical models for processes like blanching by ohmic heating are also presented.