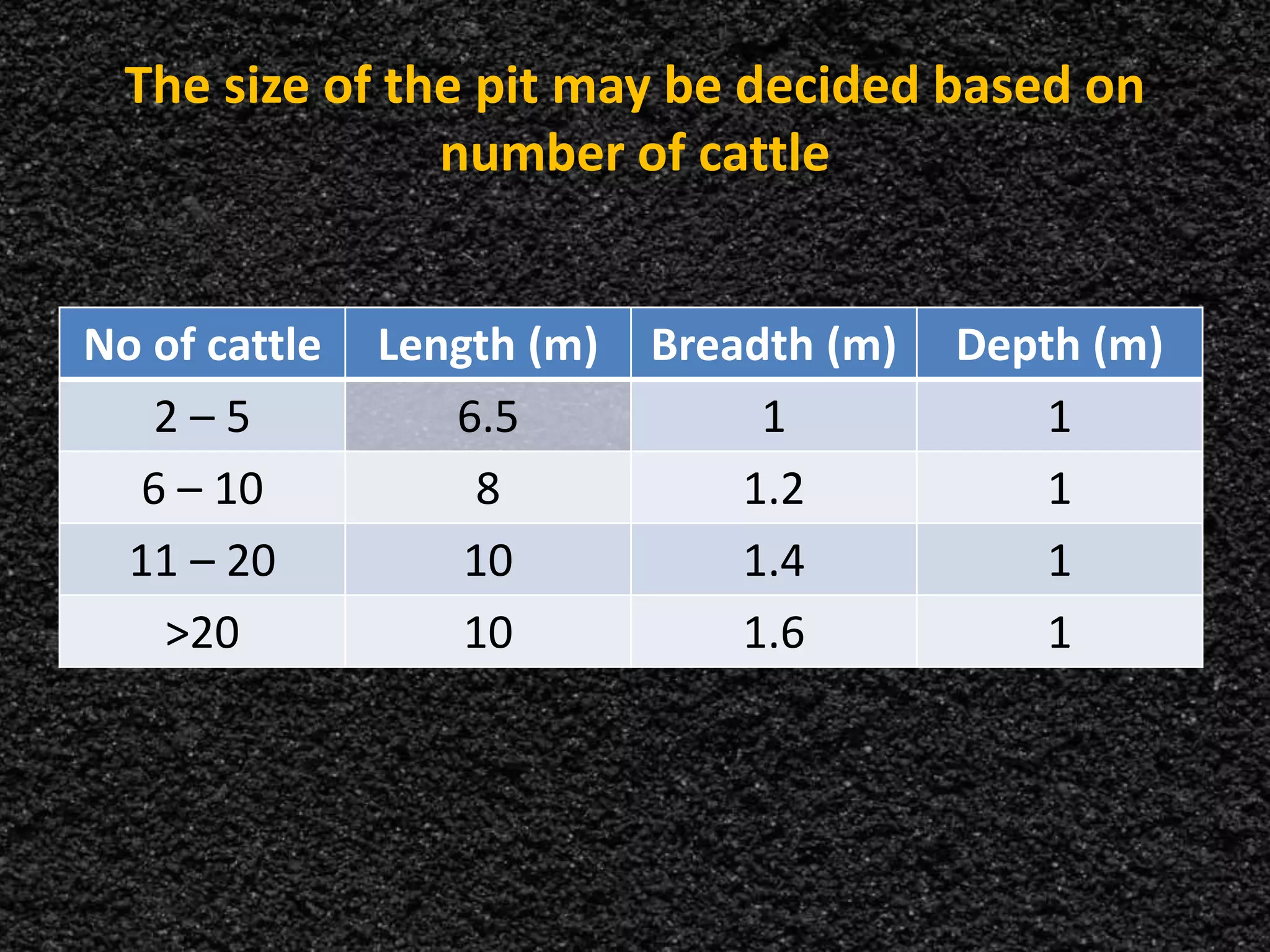

This document discusses anaerobic composting techniques. It describes three main methods - the Bangalore method, Coimbatore method, and Chinese pit method. The Bangalore method involves layering organic residues in trenches without turning for 6-8 months, resulting in bulkier compost. The Coimbatore method uses turning after 2 months in pits for faster decomposition over 6-7 months. The Chinese pit method alternates layers in circular or rectangular pits with turnings after 1-2 months for compost in 3 months. Anaerobic composting eliminates pathogens and weeds but results in lower nutrient content than aerobic methods.