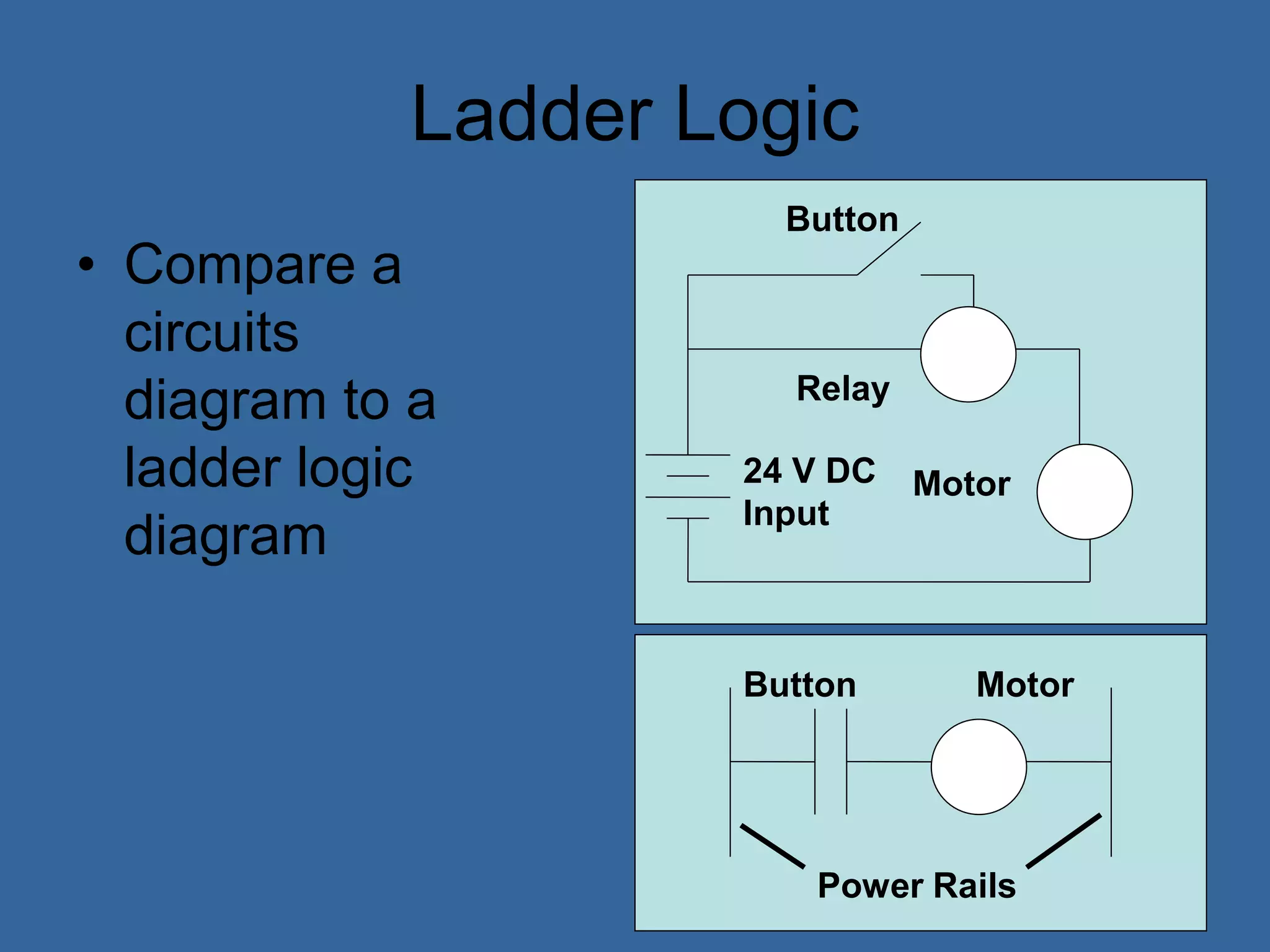

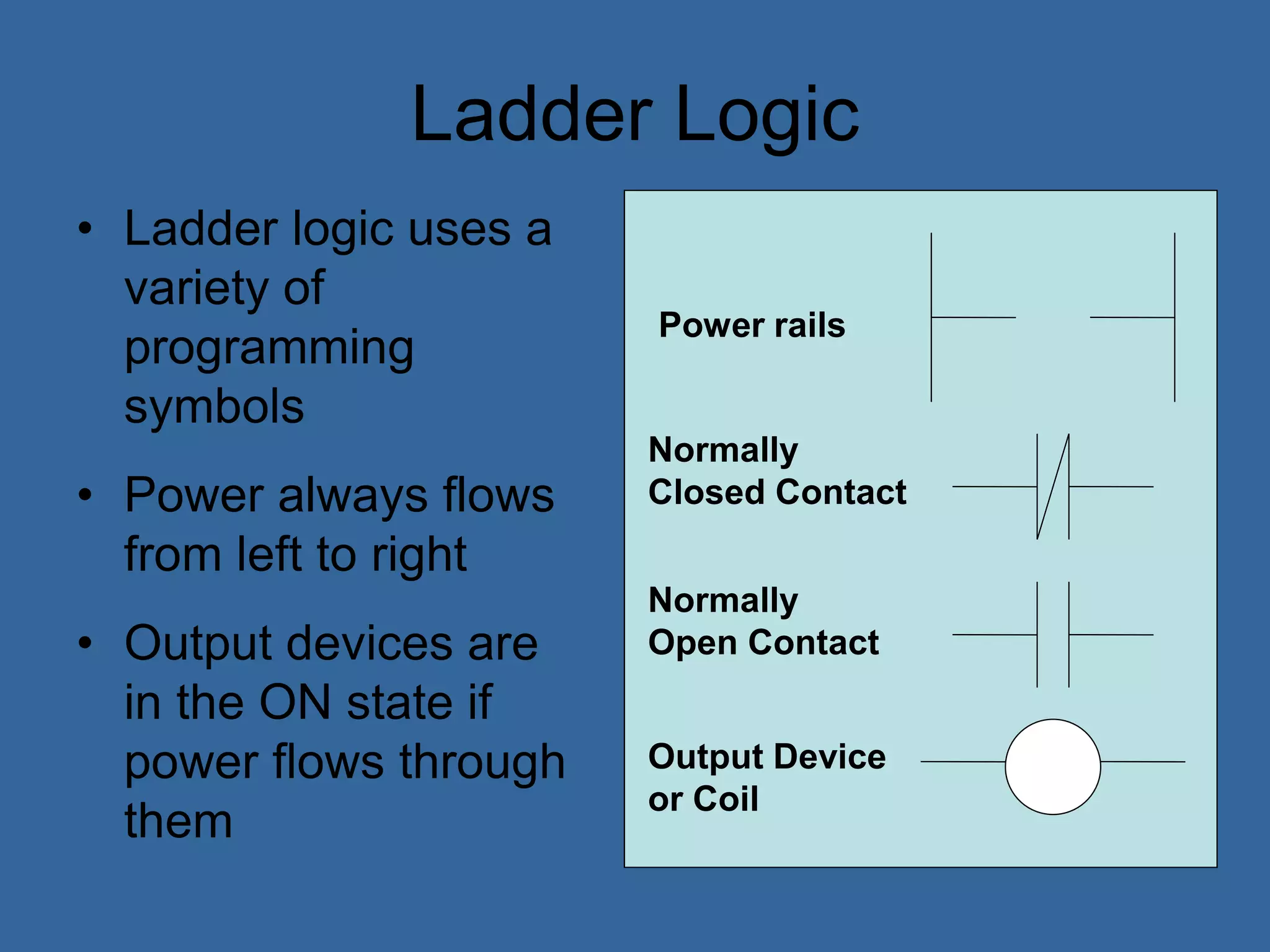

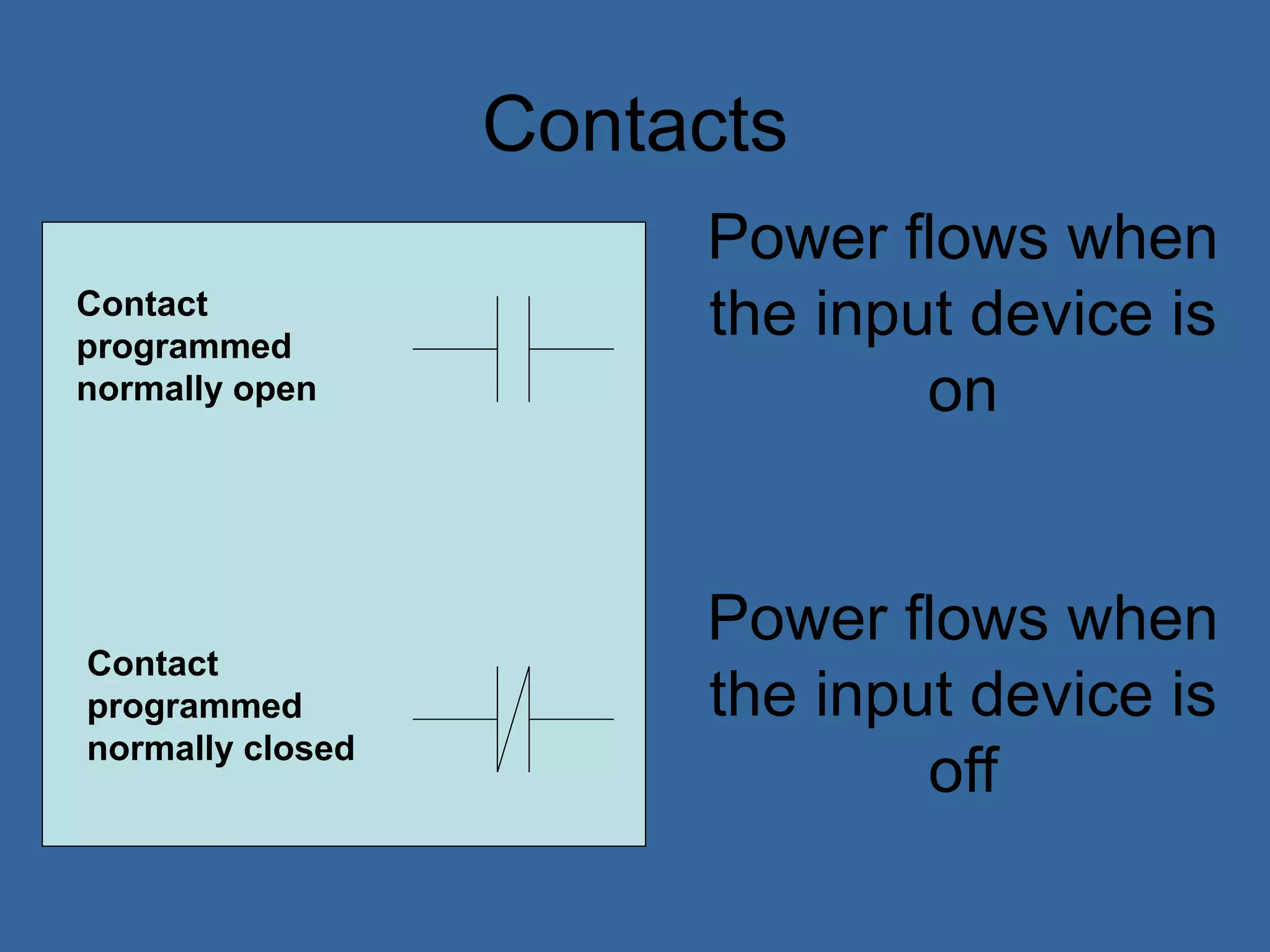

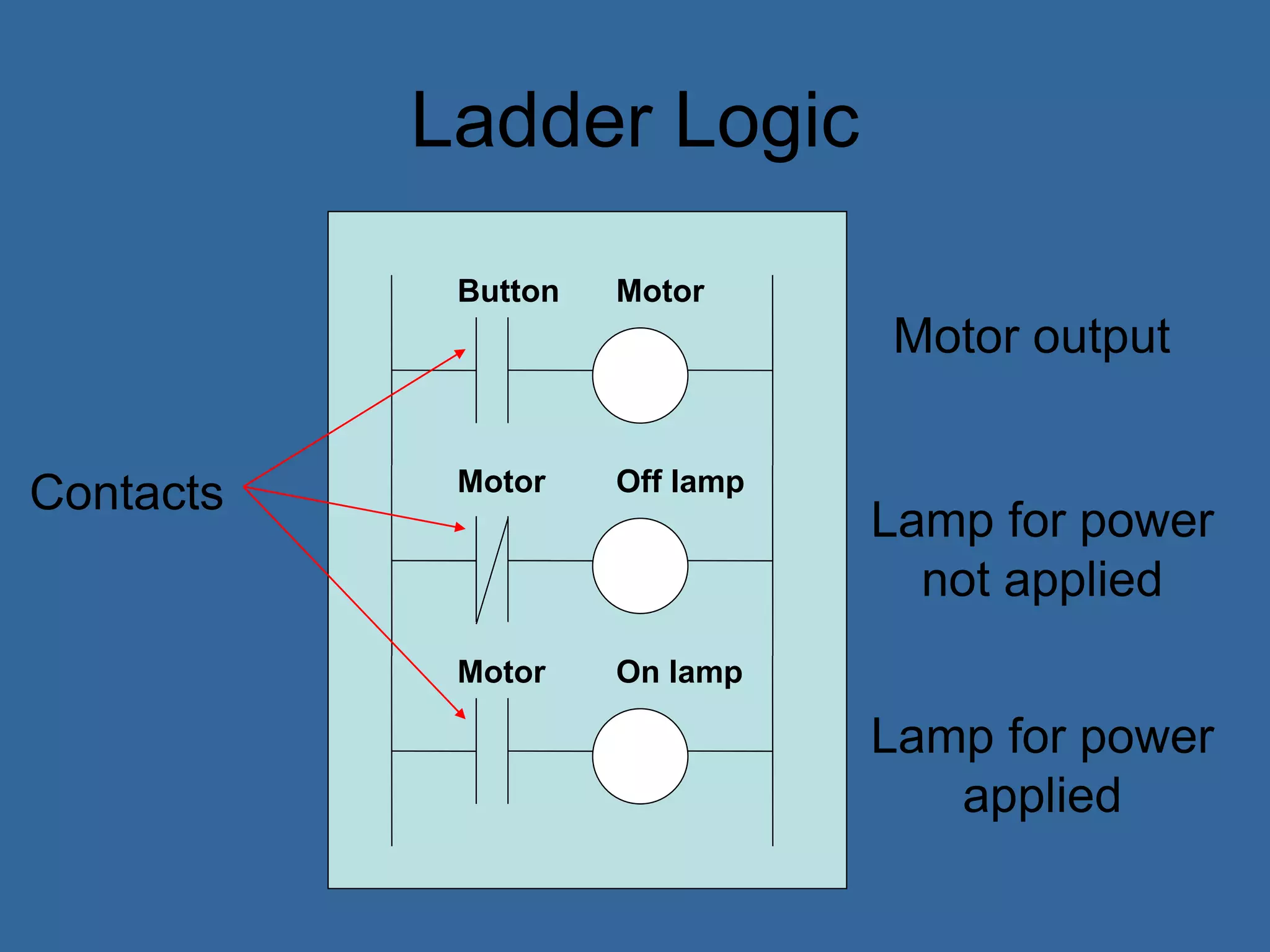

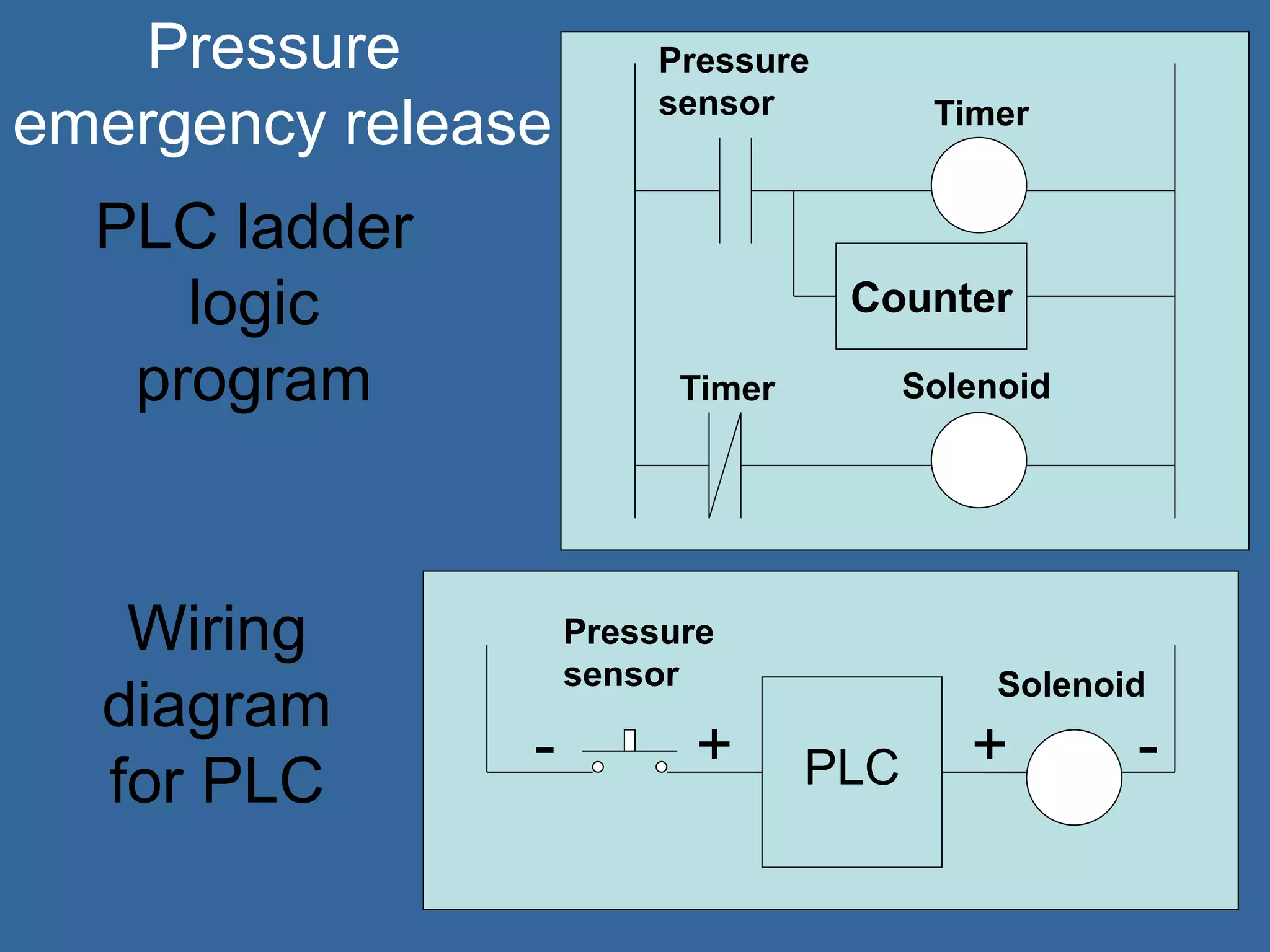

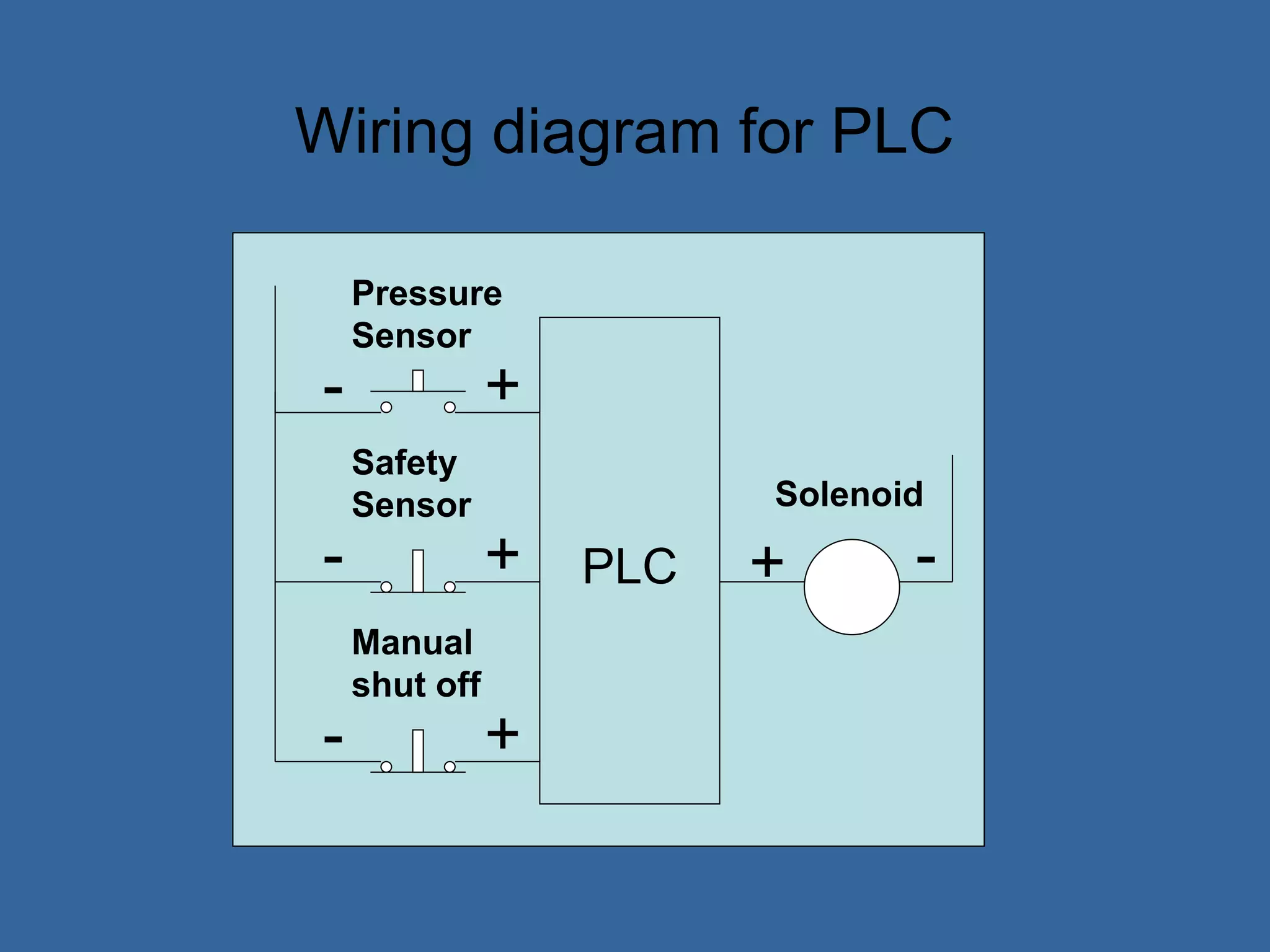

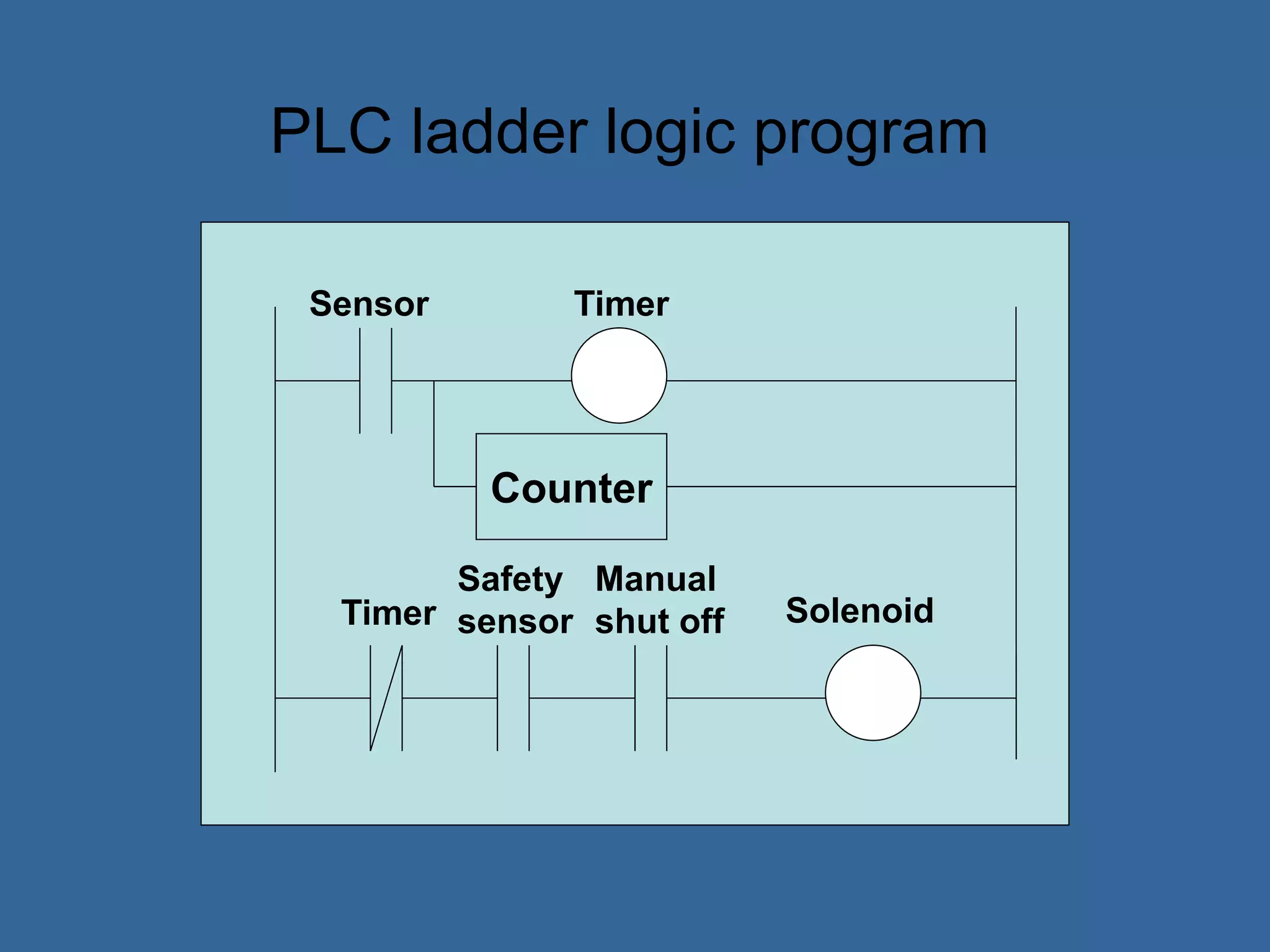

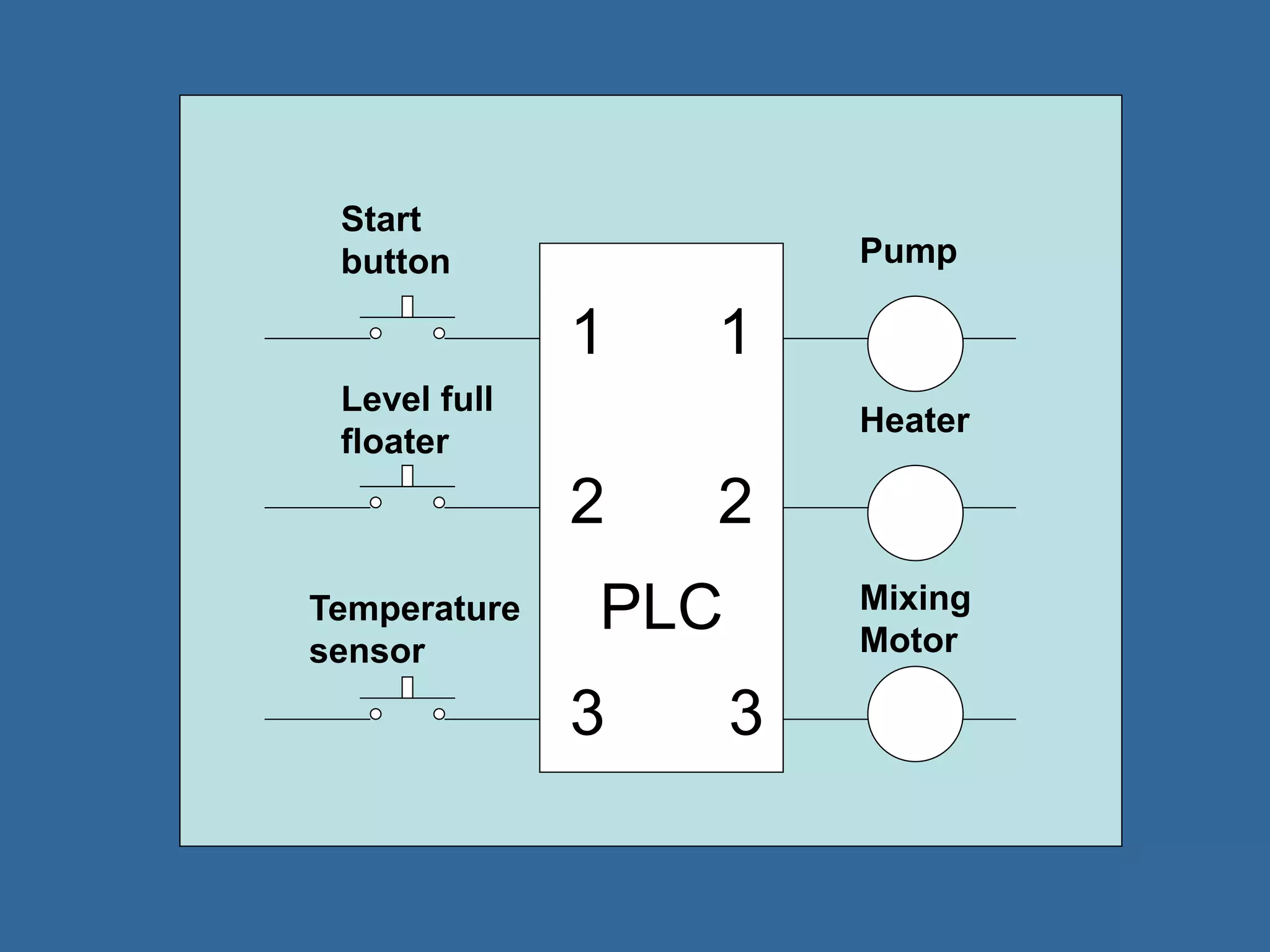

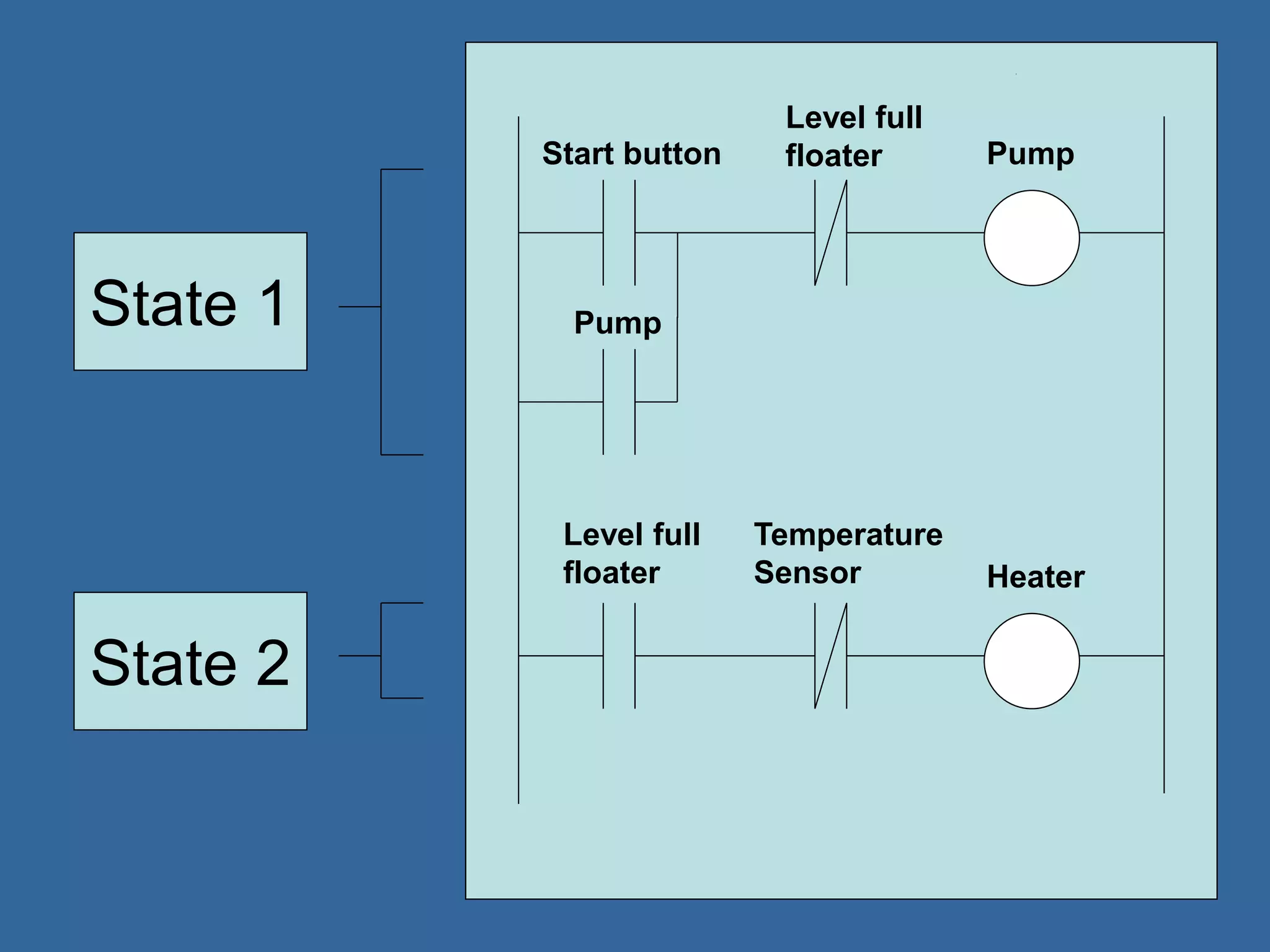

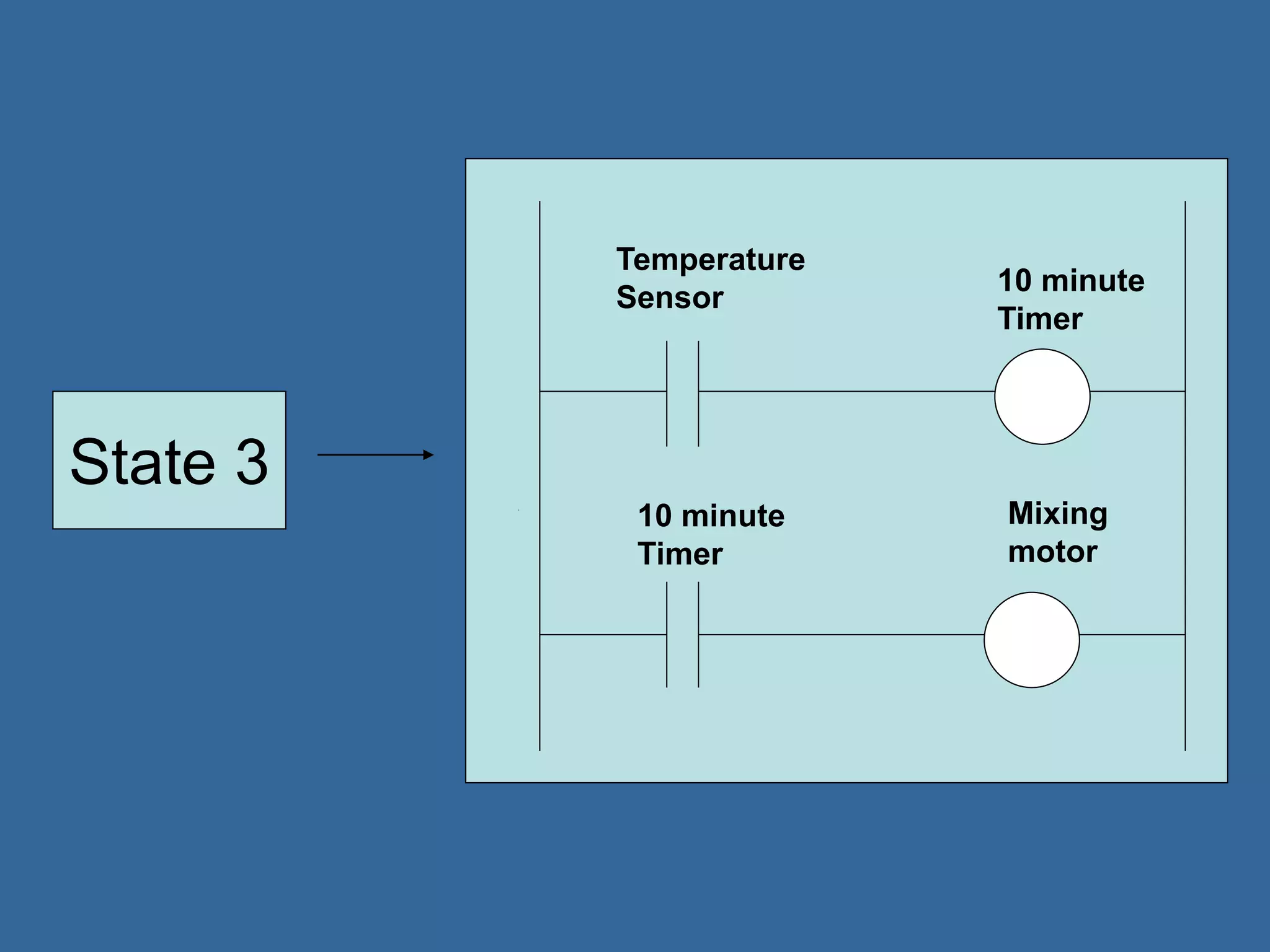

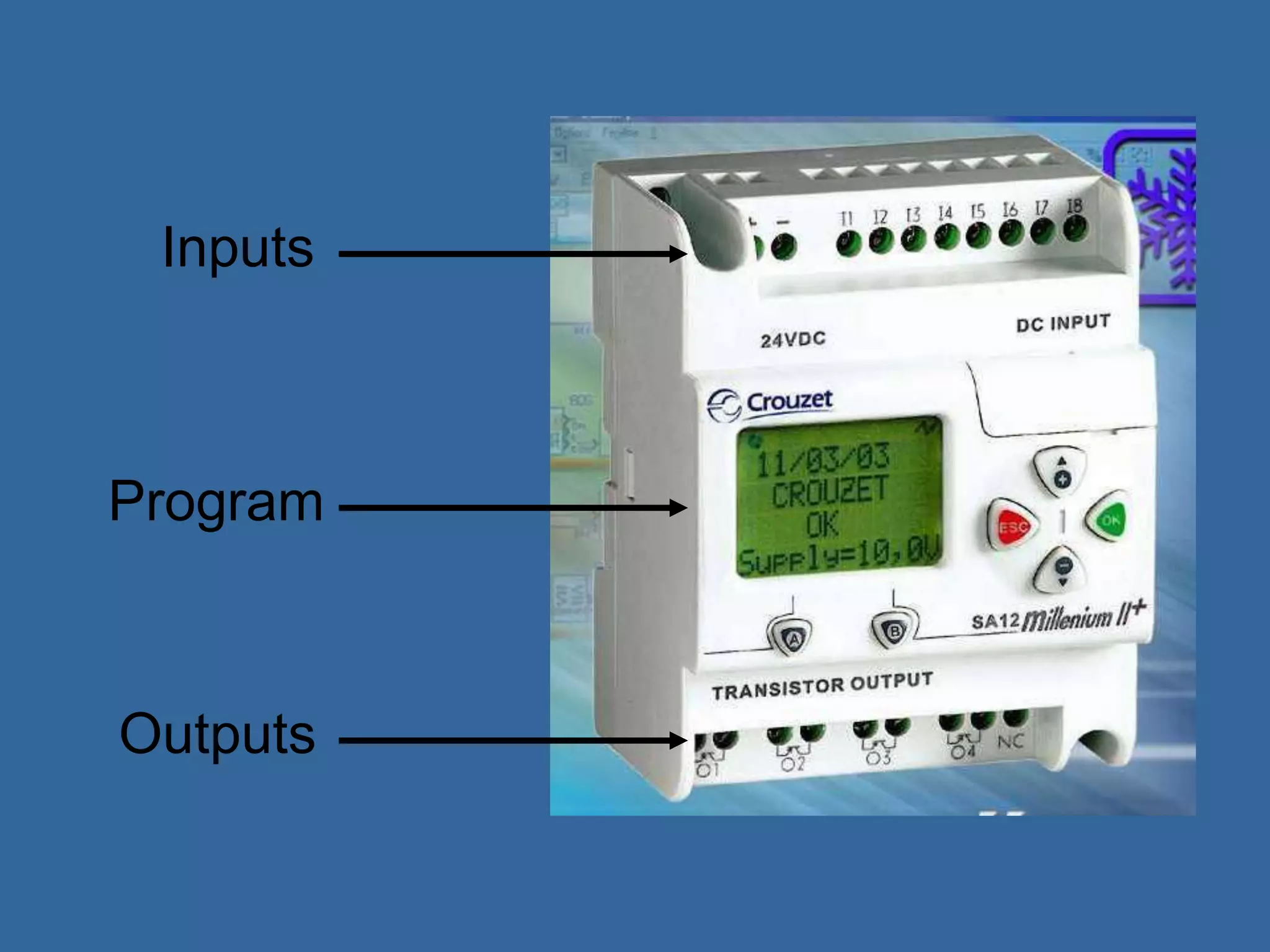

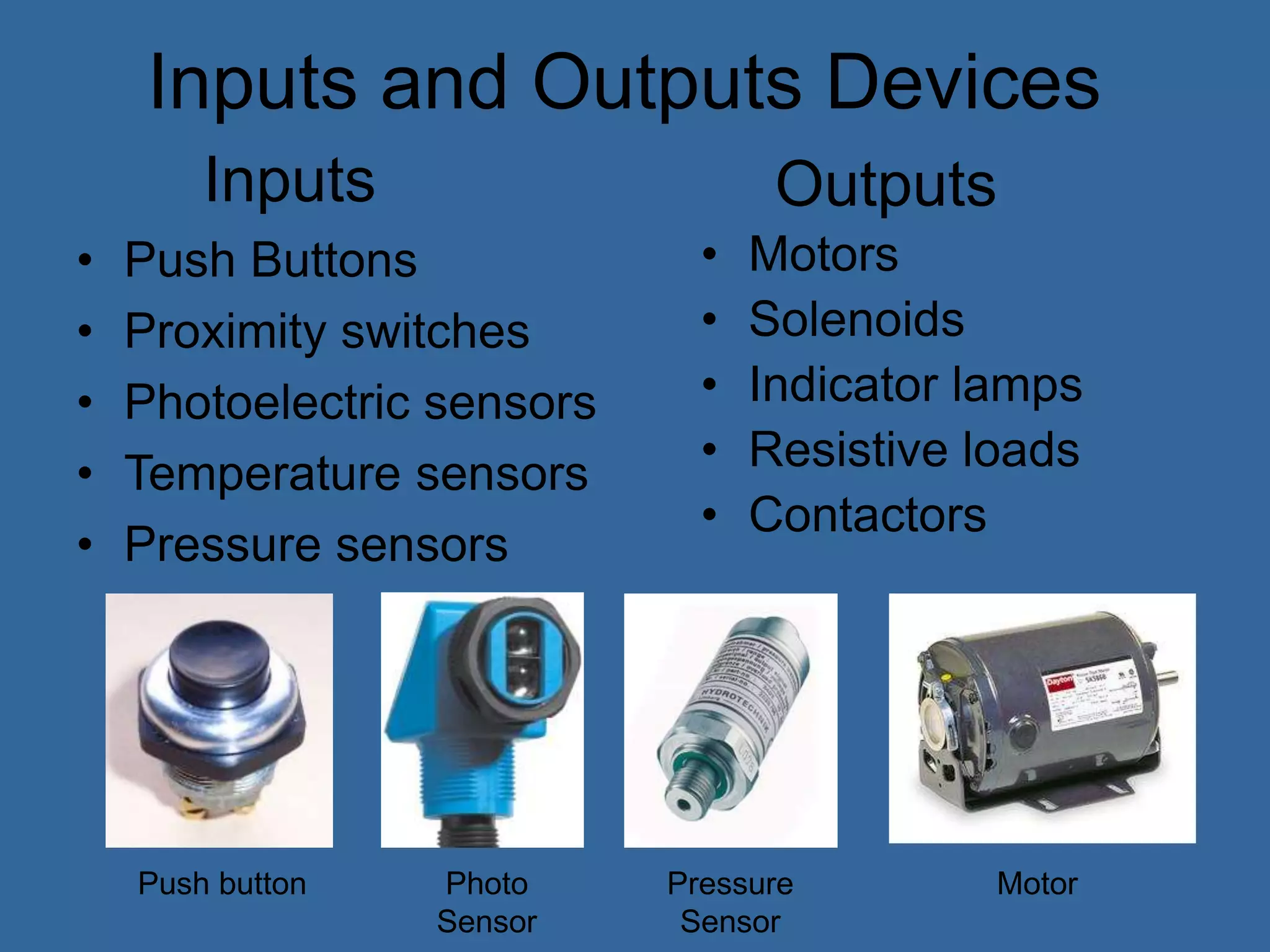

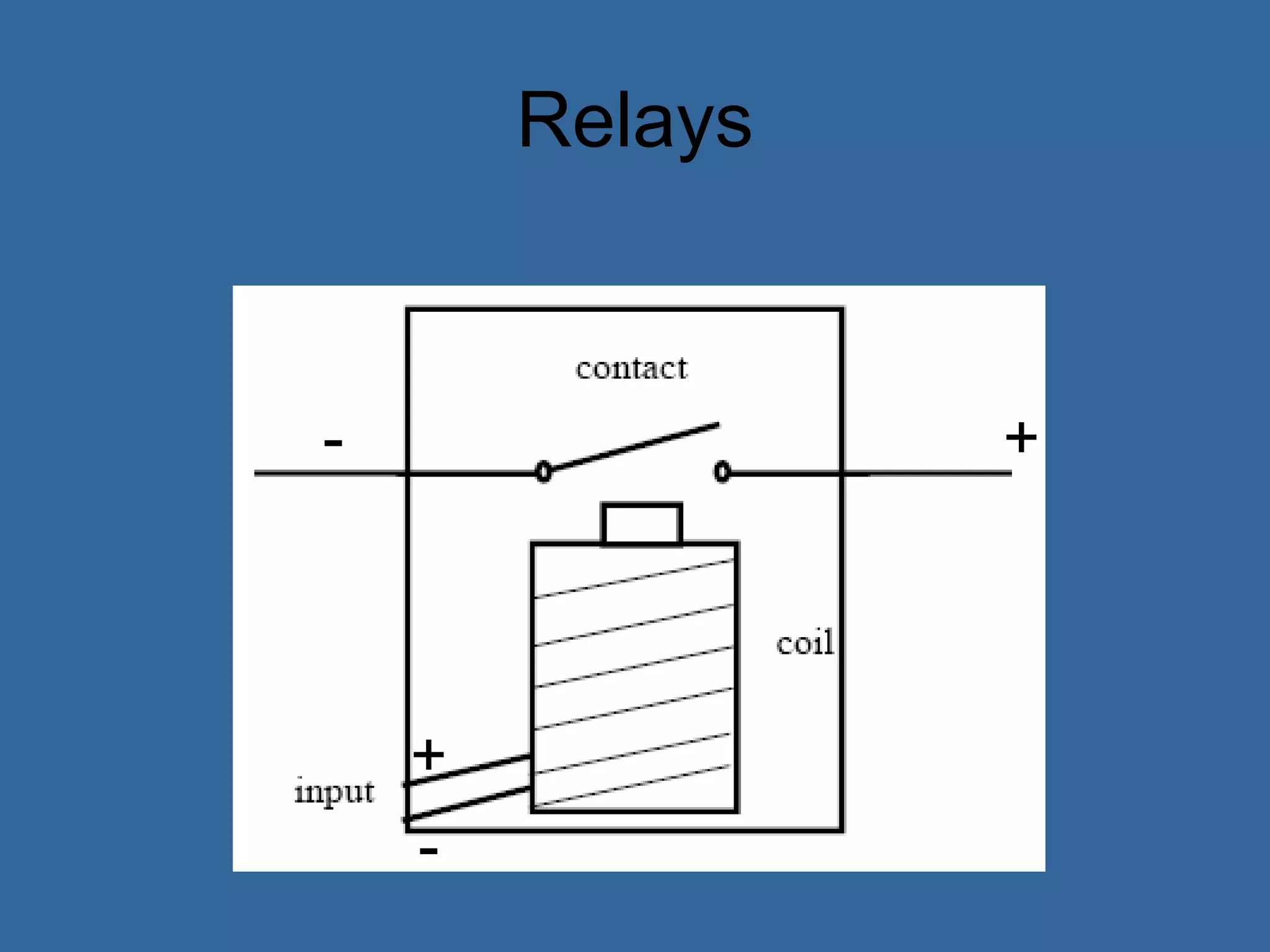

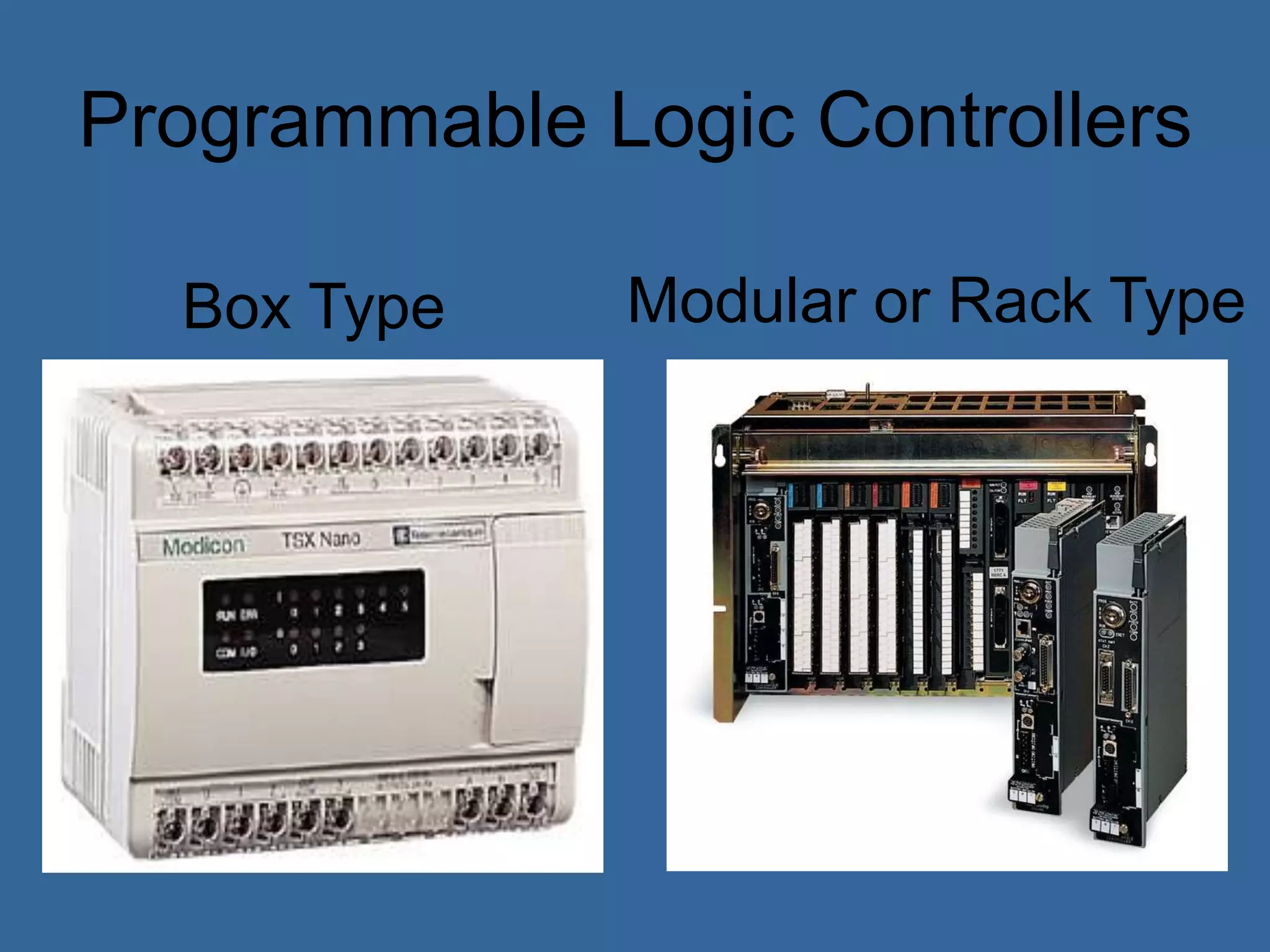

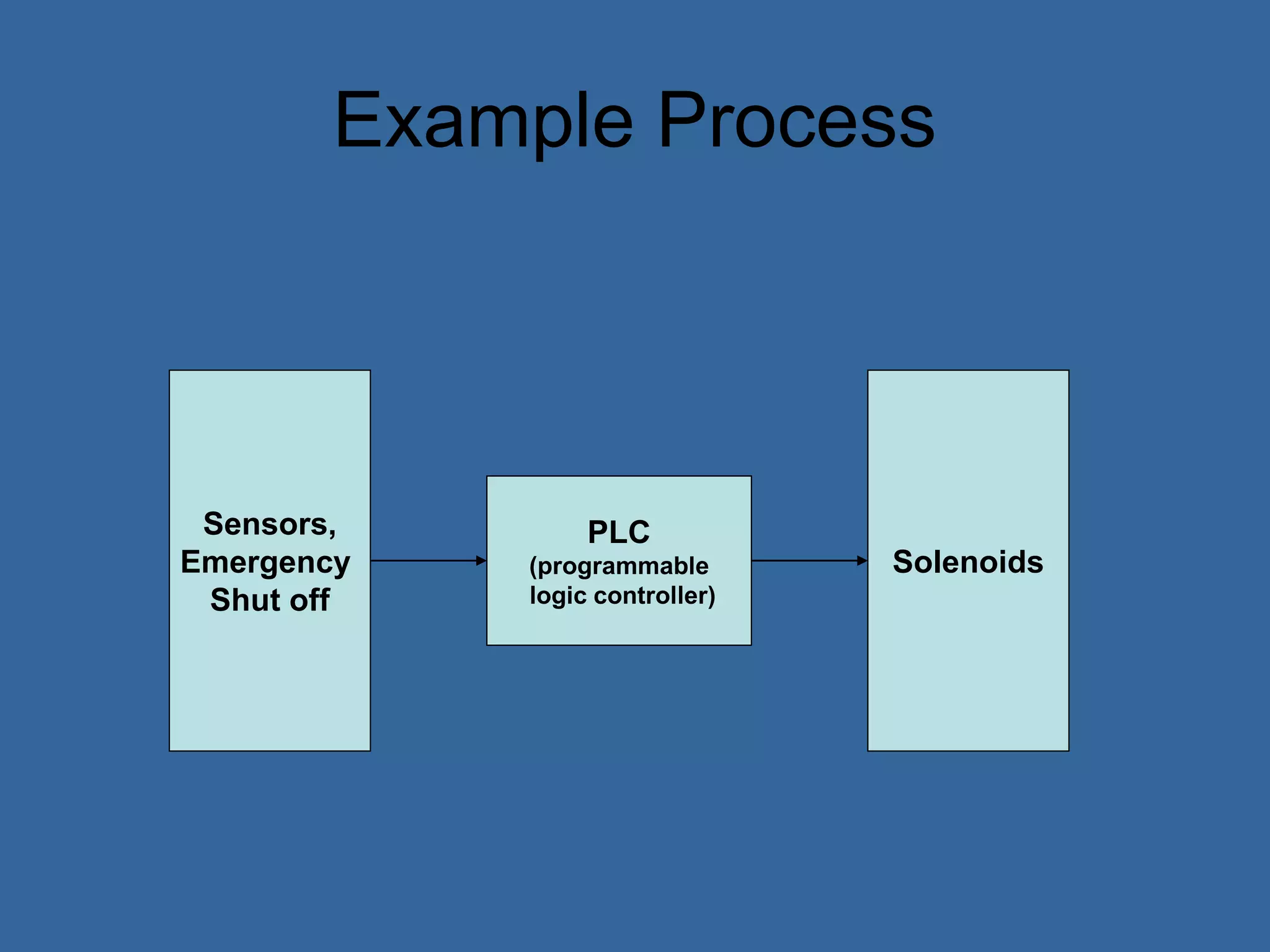

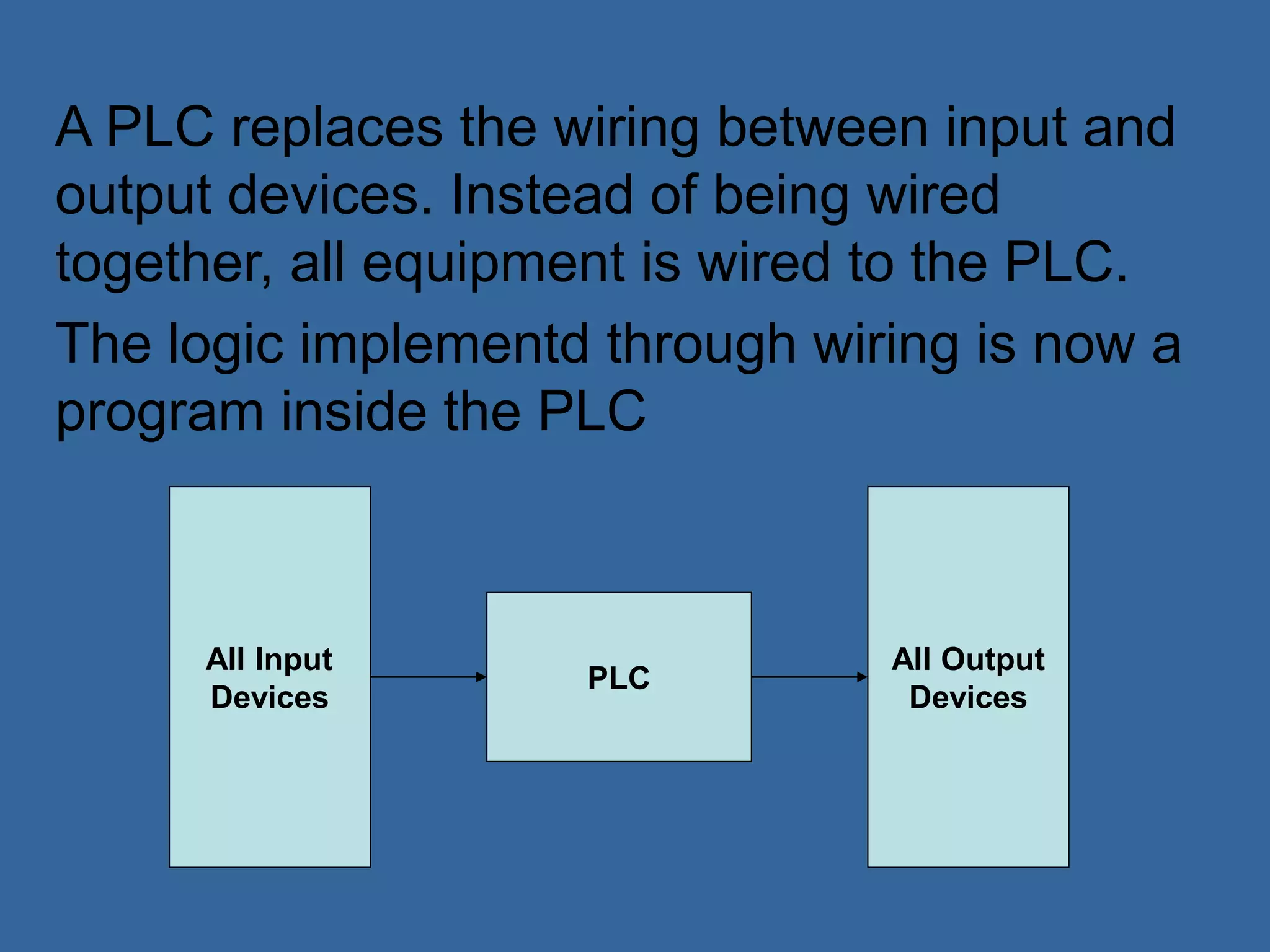

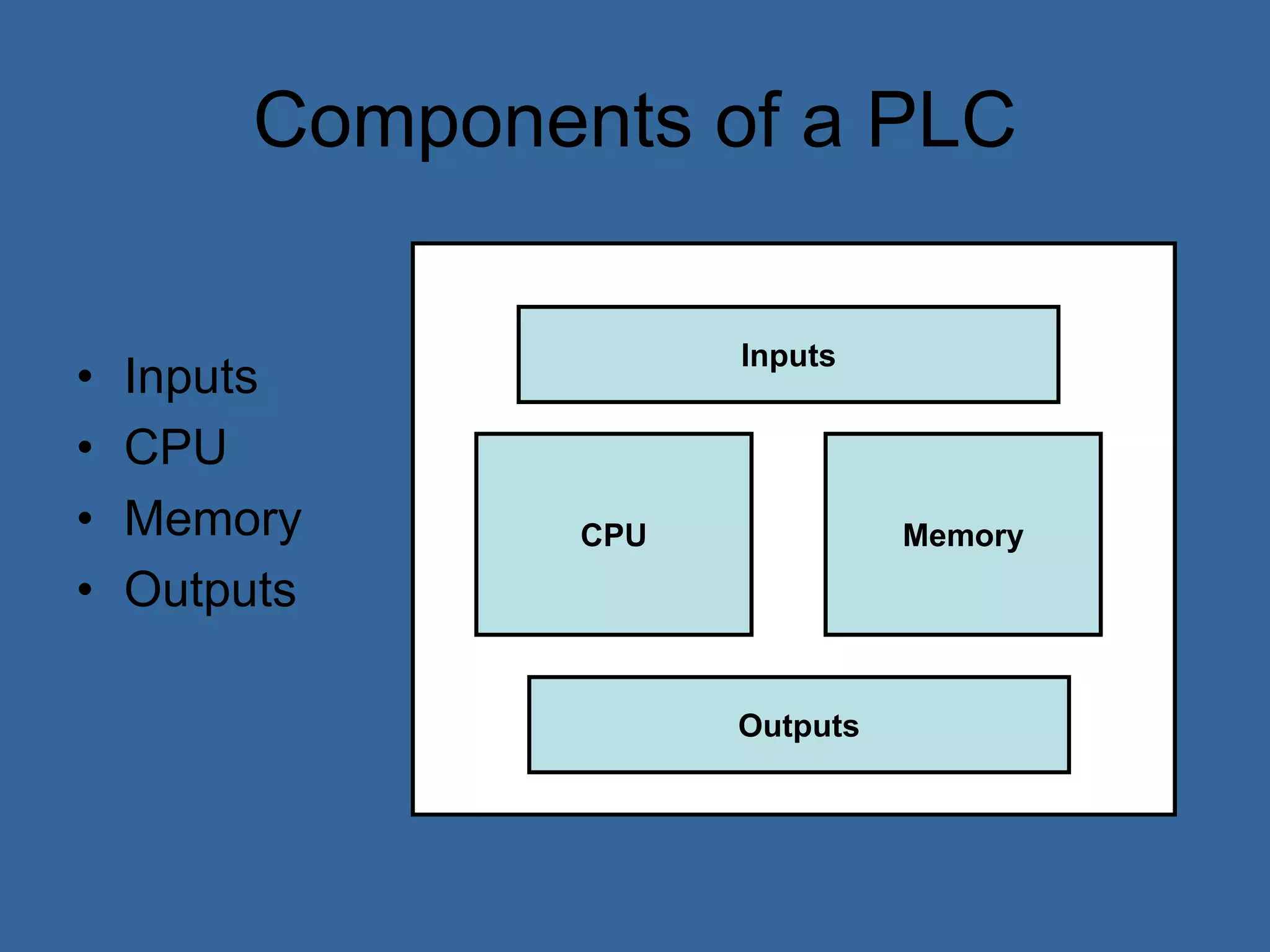

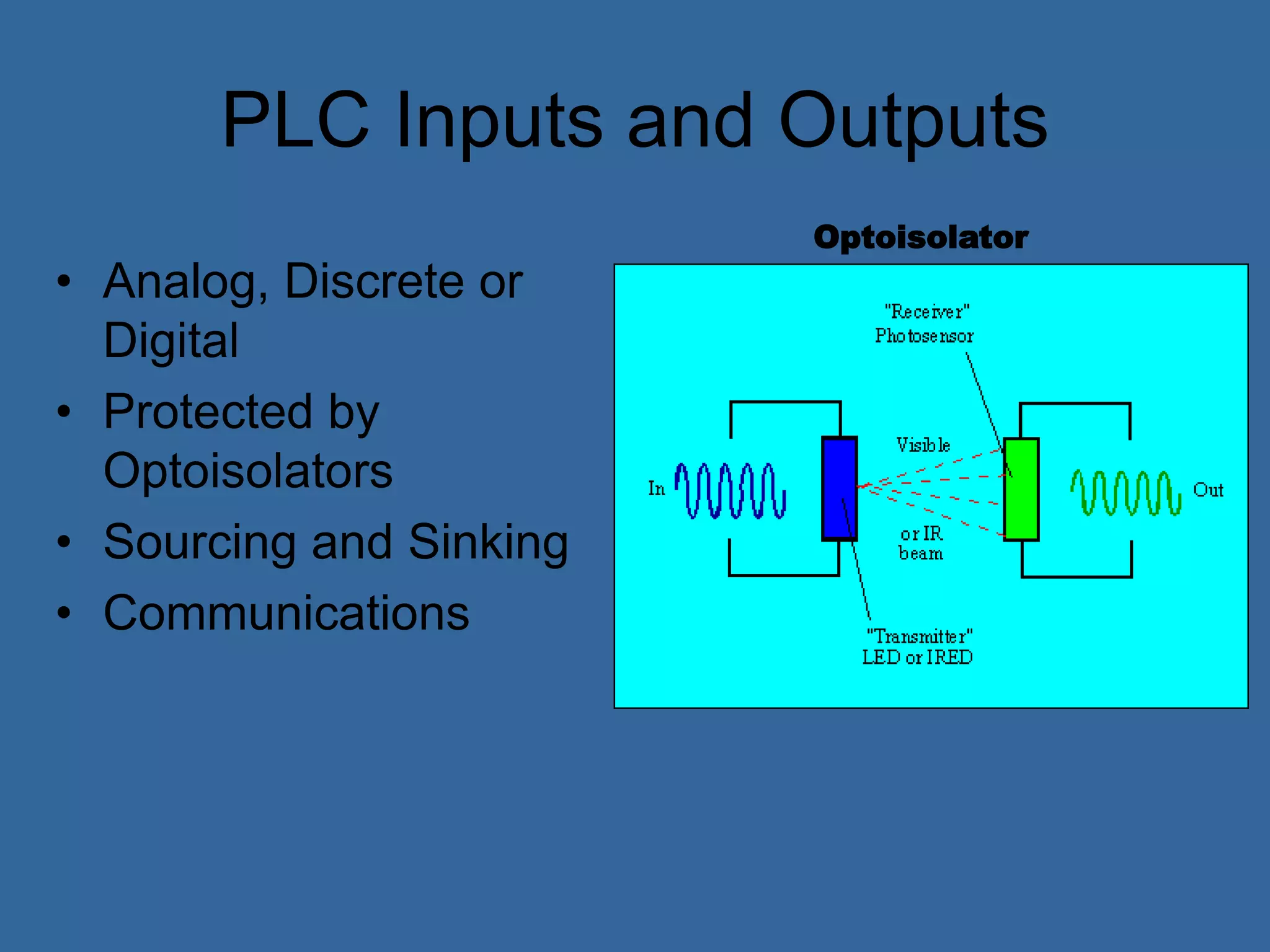

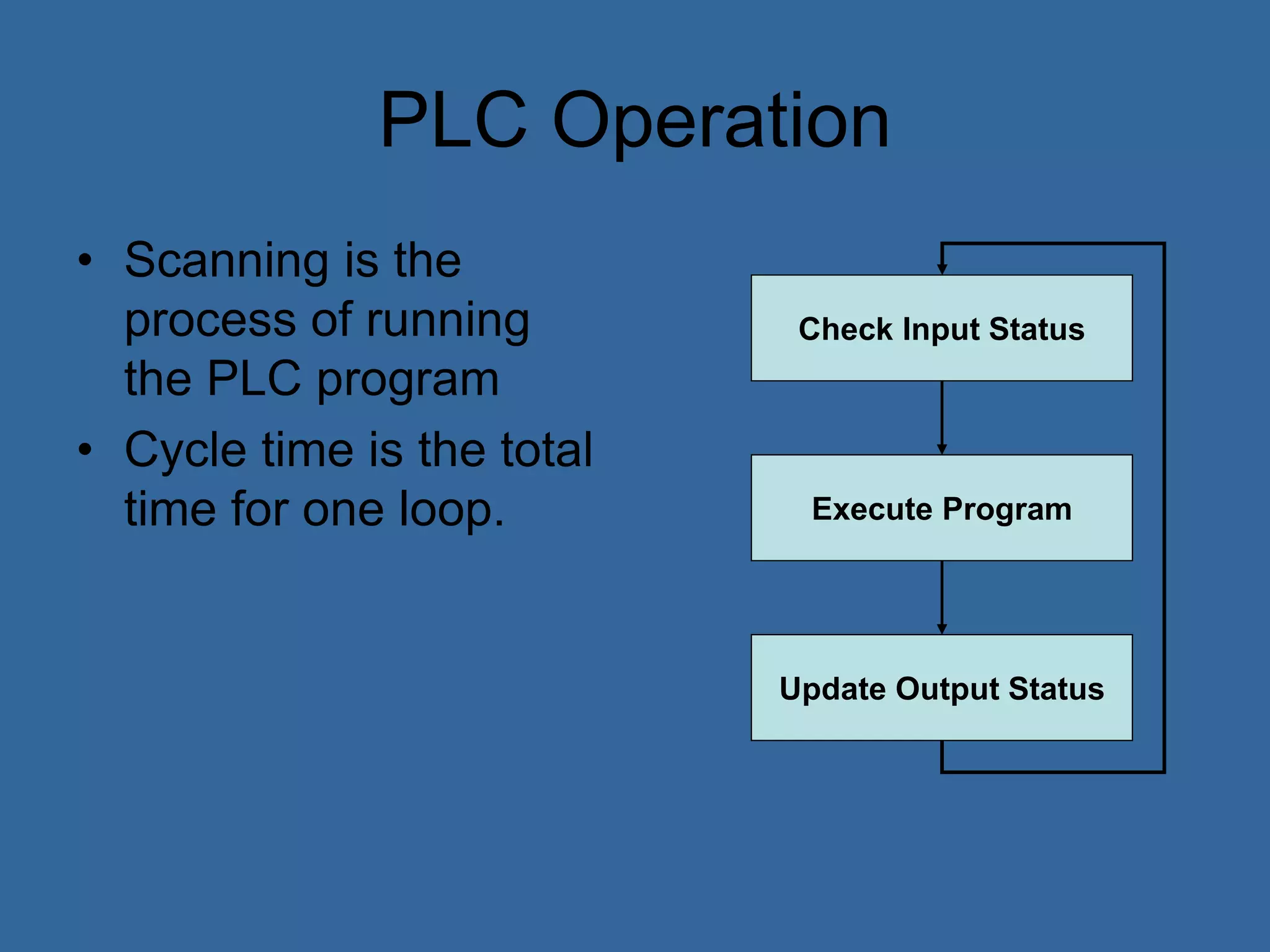

Programmable logic controllers (PLCs) are industrial computers used to monitor inputs and control outputs on automated machinery. PLCs read sensors as inputs, run user-written control programs, and activate outputs such as motors or valves. Ladder logic is the most common programming language for PLCs, resembling relay-run logic diagrams. PLCs scan inputs, execute programs, and update outputs continuously to automate industrial processes.

![Programmable Logic Controllers

• PLCs (Programmable Logic Controllers) is

a miniature industrial computer performs

control functions [4]

• The first PLCs can be traced back to 1968

and became popular in the 1980’s [4]

• PLCs are rugged and designed to

withstand the industrial environment.](https://image.slidesharecdn.com/anintroductiontoplcs-200115170620/75/An-introduction-to-pl-cs-16-2048.jpg)

![PLC Programming

• Ladder logic is the main programming

method used for PLCs [39]

• It is a visual and symbolic programming

language that resembles relays logic

diagrams

• Ladder logic has been developed to mimic

relay logic to reduce amount of retraining

needed for engineers and trades people

[39]](https://image.slidesharecdn.com/anintroductiontoplcs-200115170620/75/An-introduction-to-pl-cs-20-2048.jpg)