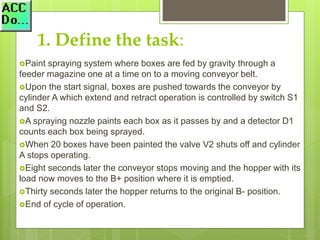

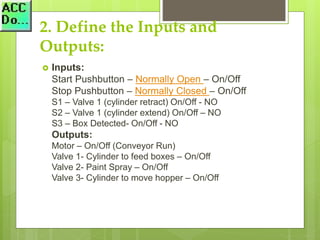

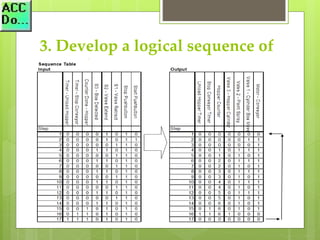

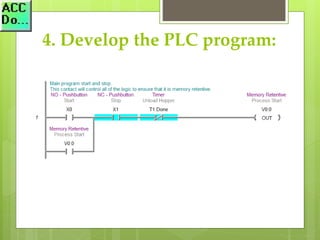

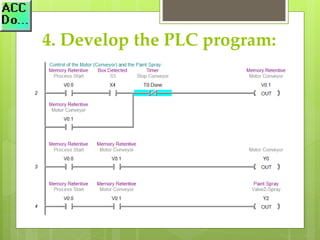

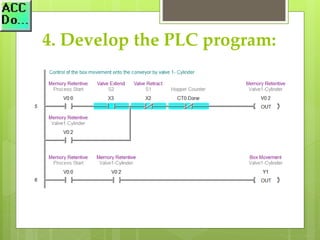

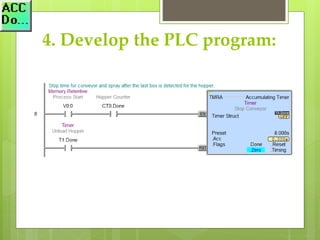

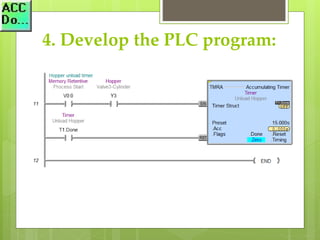

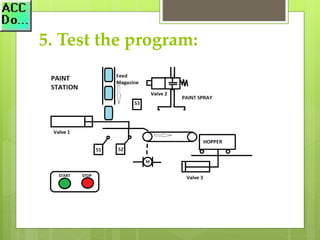

The document outlines a 5-step process for developing a PLC program for a paint spray application system. The steps are: 1) define the task, 2) define inputs and outputs, 3) develop a logical sequence of operation using a flowchart, 4) develop the PLC program, and 5) test the program. It then provides details for each step as applied to a conveyor system that feeds boxes through a spray nozzle, with inputs like start/stop buttons and outputs like conveyor motor and spray valve control.