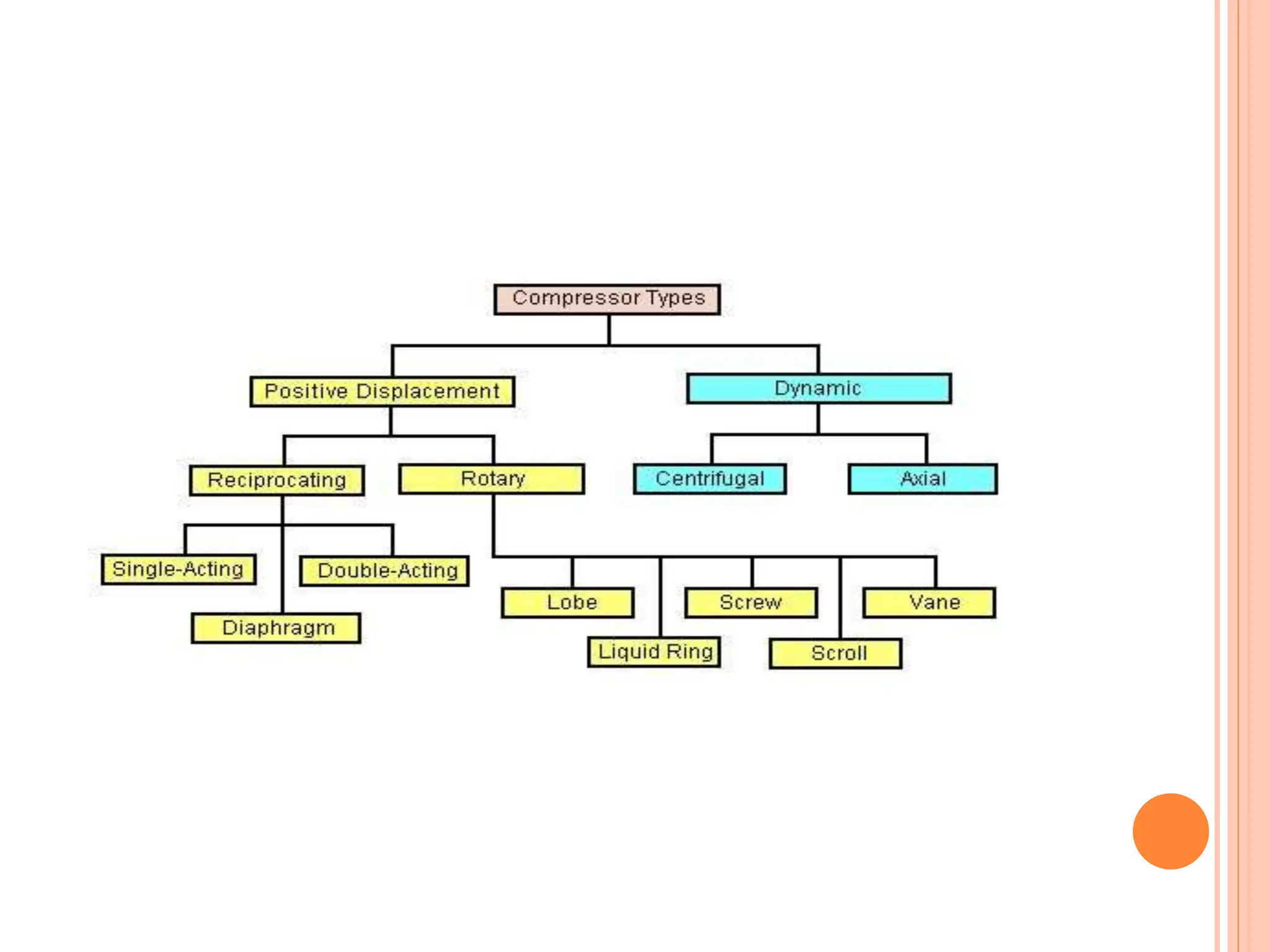

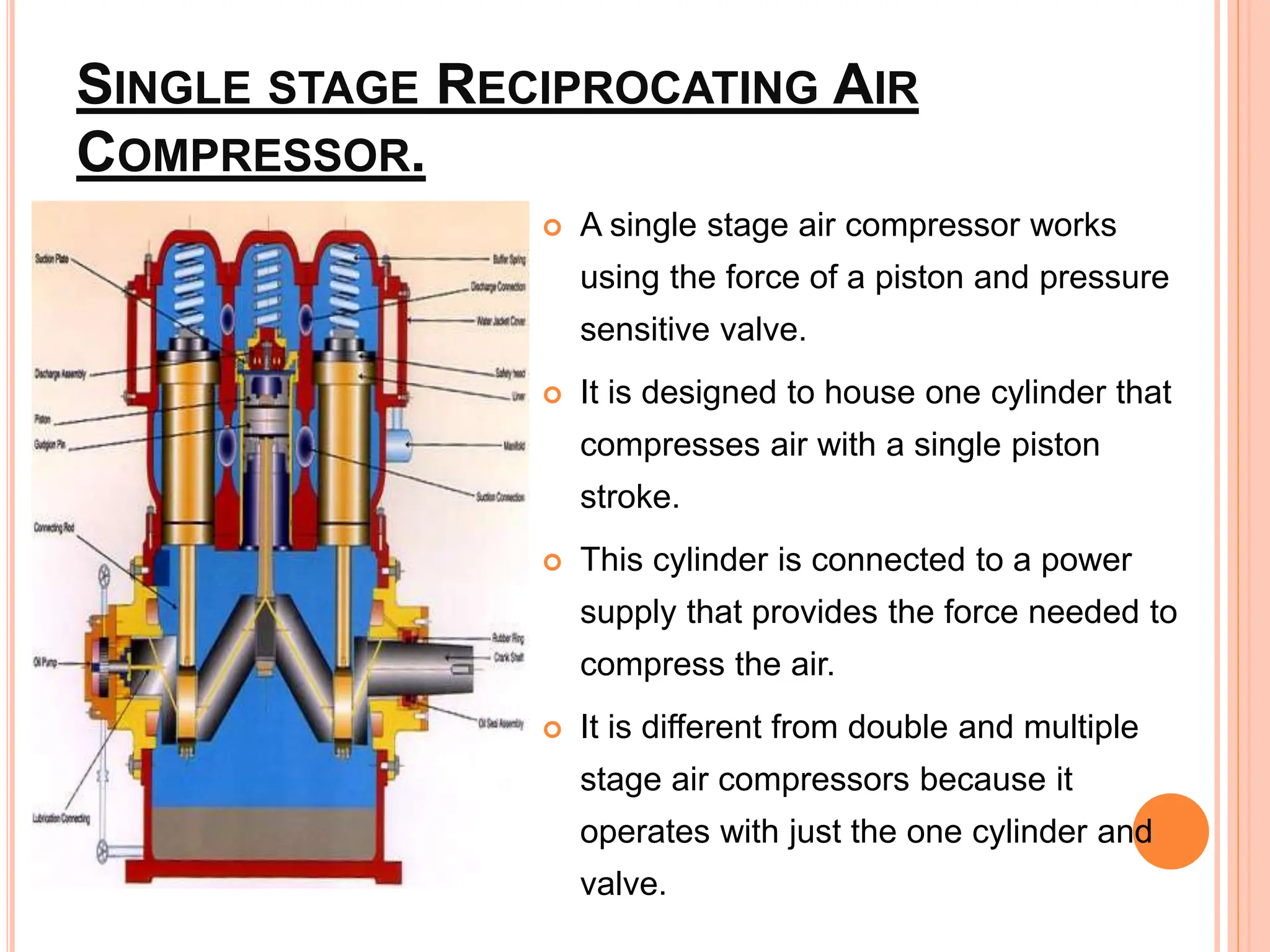

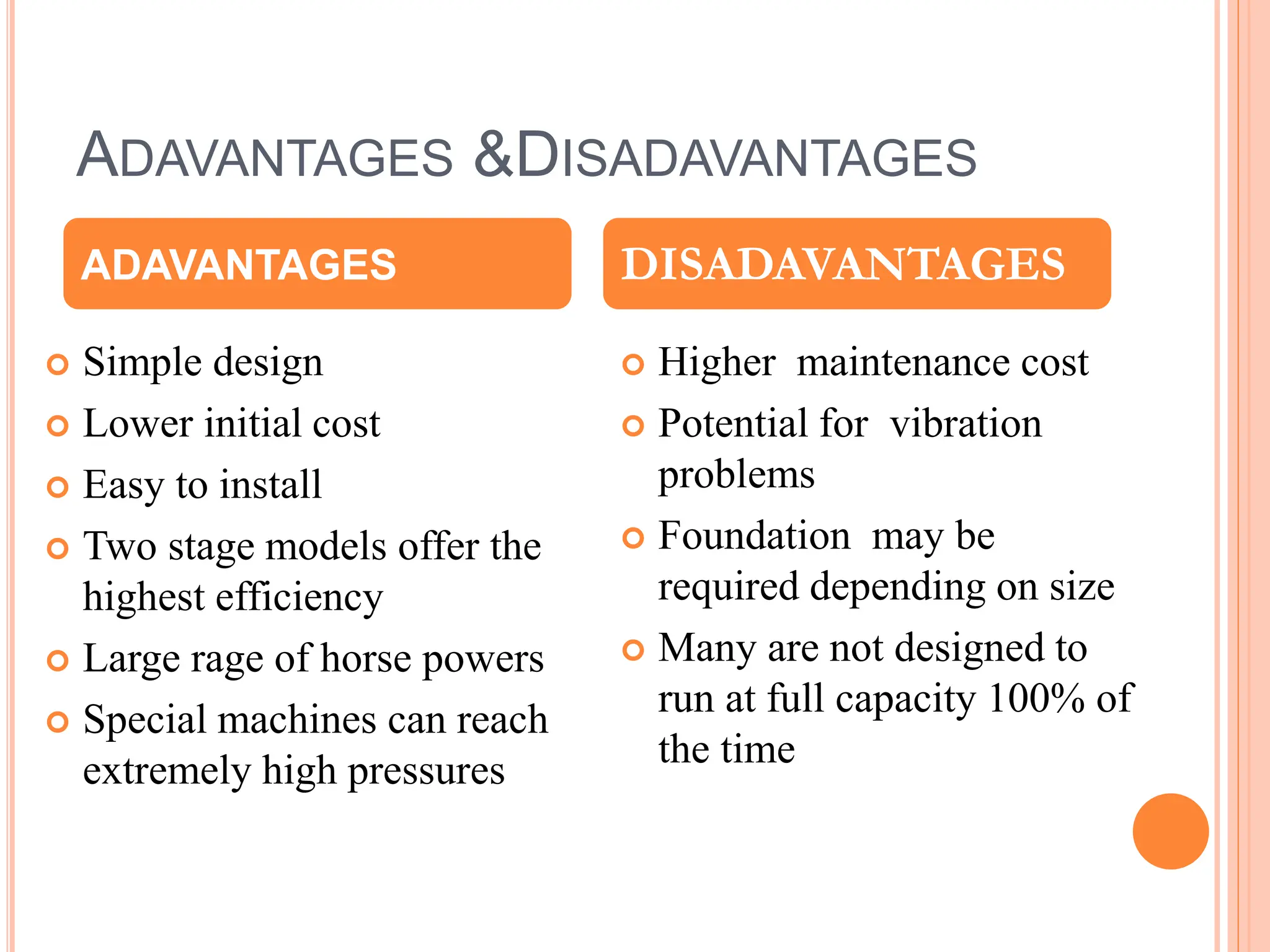

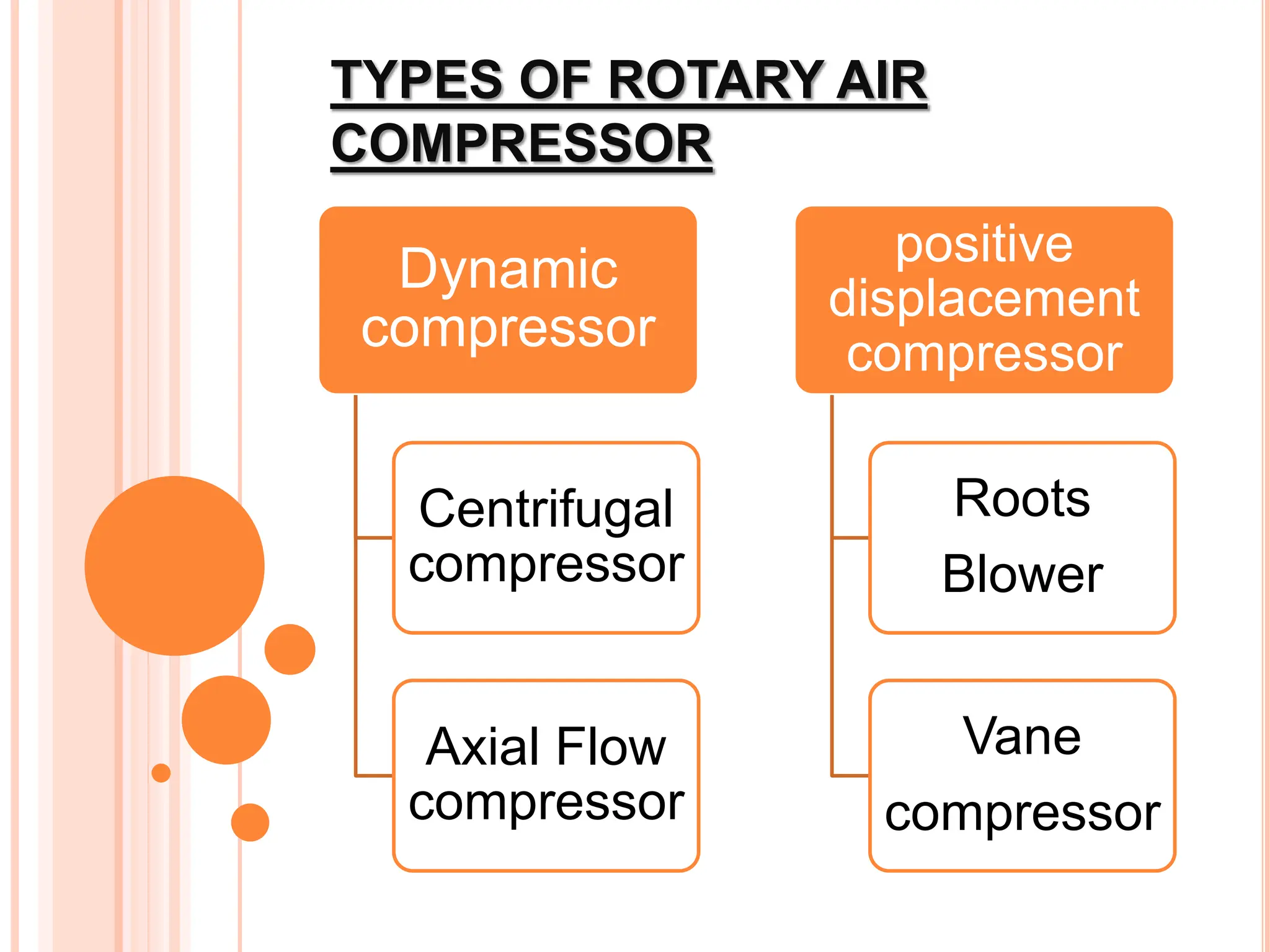

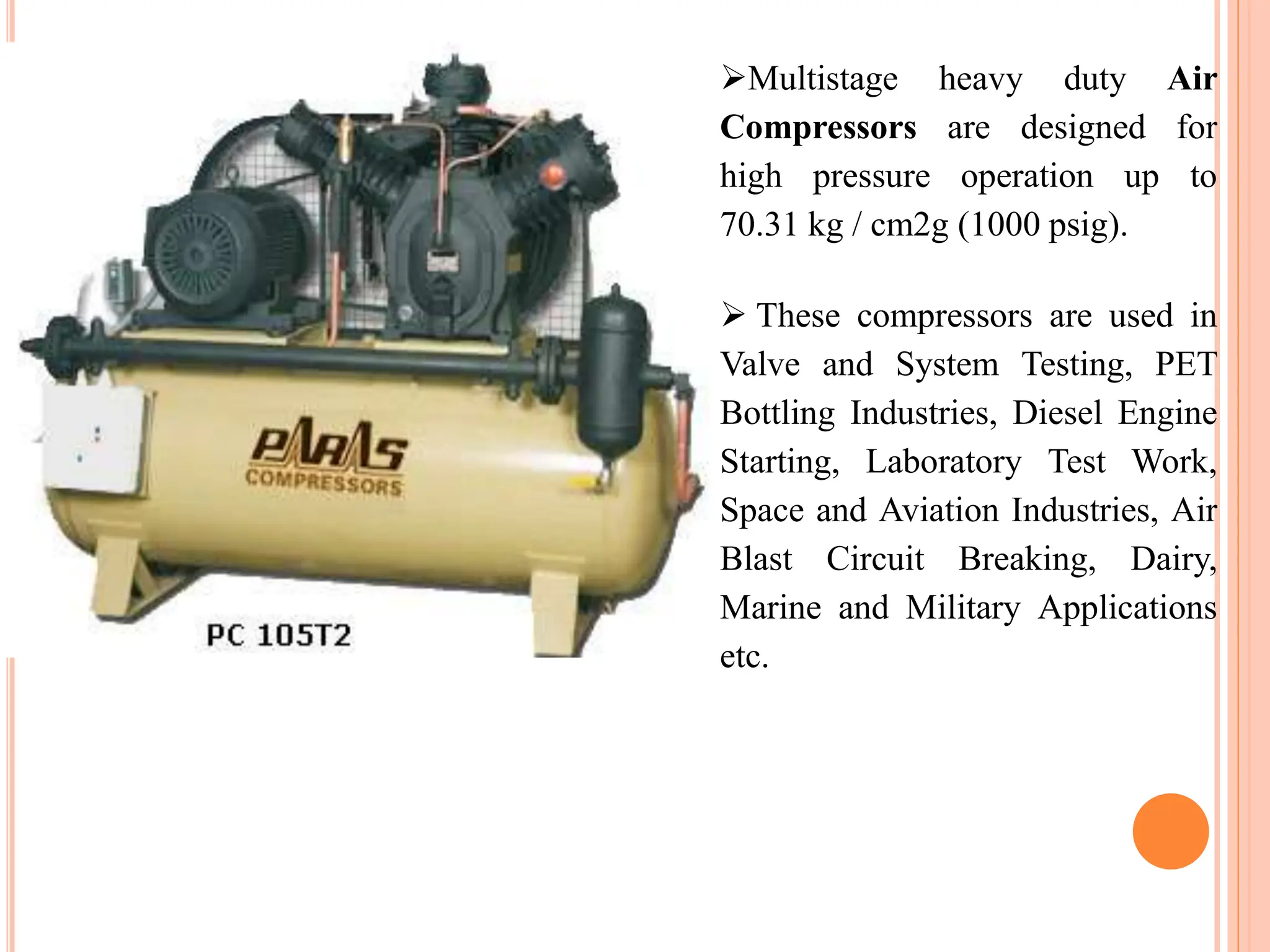

The document discusses air compressors, detailing their function of converting power into kinetic energy through the compression and pressurization of air. It covers various types of compressors, including single-stage and multi-stage reciprocating compressors, and rotary compressors, highlighting their applications, advantages, and disadvantages. It also compares the performance and efficiency of single-stage versus multi-stage systems and elaborates on the importance of multi-stage compression in specific industries.