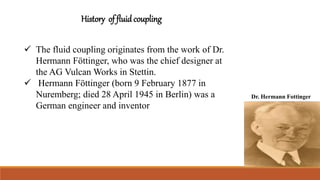

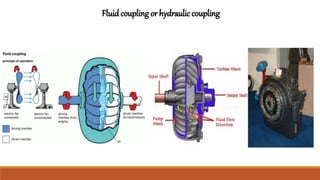

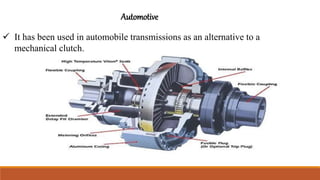

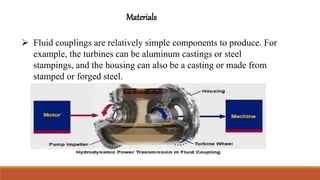

This document discusses fluid couplings. It begins by defining a fluid coupling as a hydrodynamic device that transmits rotating mechanical power without a direct mechanical connection between driving and driven shafts. It then provides a brief history, overview of components (housing, input and output turbines), working principle (how fluid moves between turbines to transfer torque), typical materials, and applications in industries like power plants, mines, refineries, automotive, and aviation. Advantages include soft starts and load sharing, while disadvantages include potential damage under stall conditions when power is dissipated as heat.