The document provides information about:

1) The objectives of the aeronautical engineering project, which are to teach students how to analyze load-bearing structures and various analysis methods.

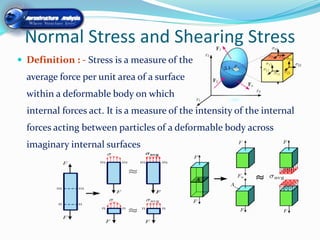

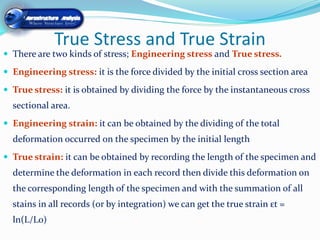

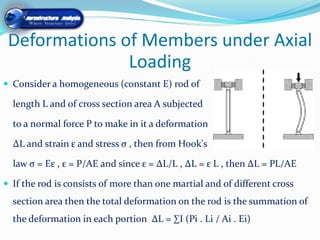

2) The different types of stresses acting on structures like normal stress, shearing stress, and how they relate to forces and deformations.

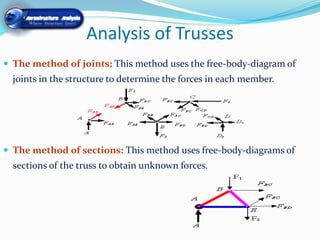

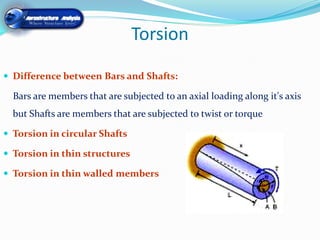

3) Additional structural analysis concepts covered include truss analysis methods, strains under axial loading, temperature effects, and torsion in circular and thin-walled members.