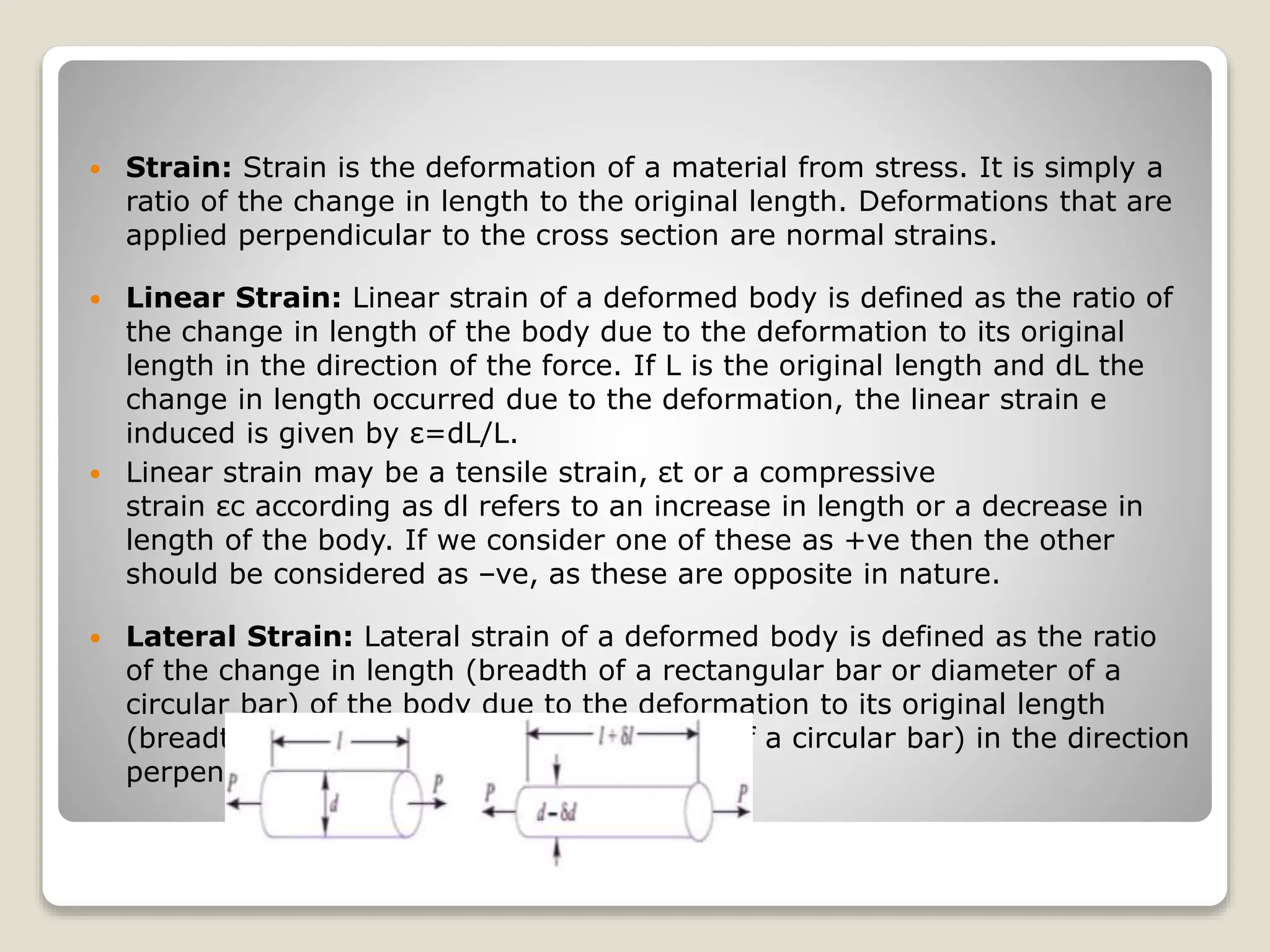

The document discusses the mechanics of materials, focusing on stress and strain, defining stress as the force per unit area and differentiating between types of stress such as normal, shear, and bearing stress. It also explains various strains including linear, lateral, and volumetric strains, alongside Hooke’s Law that relates stress and strain within the elastic limit. Additionally, it covers elastic constants like modulus of elasticity, modulus of rigidity, and bulk modulus, and introduces key material properties including elasticity, plasticity, ductility, and toughness.