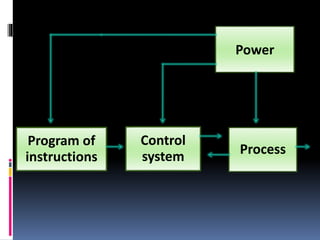

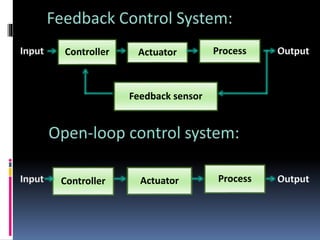

There are three basic elements of an automated system: a power source, a programmable command, and control systems. Electricity is commonly used as the power source to drive both the automated process and control systems. A programmable command consists of a set of instructions that specify the sequence and details of each step in the work cycle. Control systems execute the program of instructions and use feedback sensors to regulate the process via closed-loop control and ensure it carries out the intended manufacturing operation.