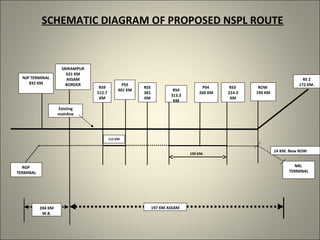

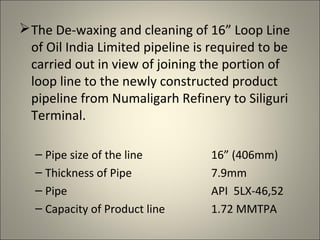

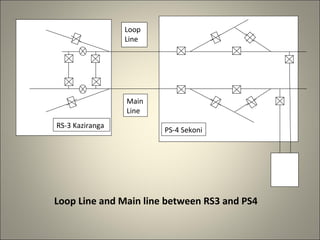

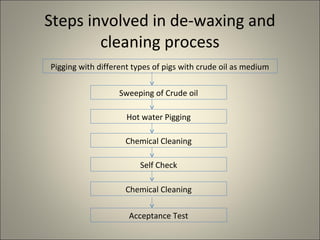

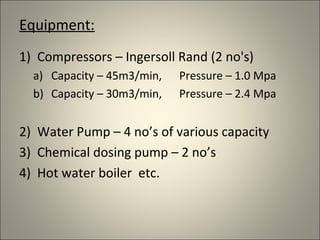

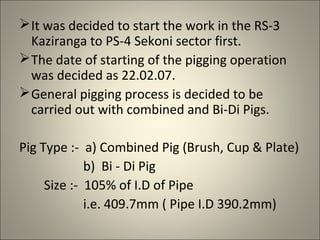

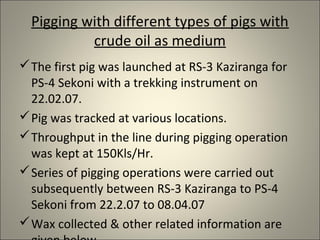

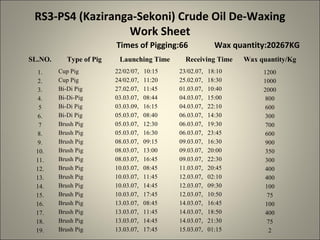

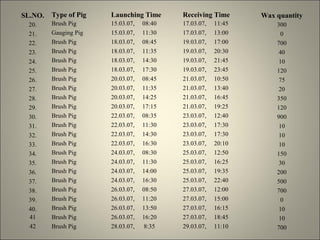

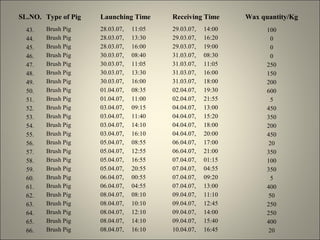

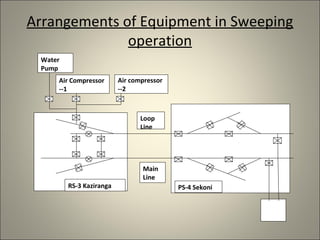

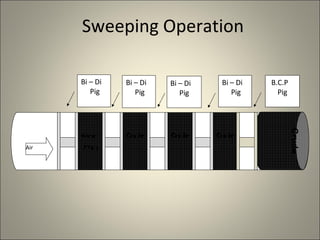

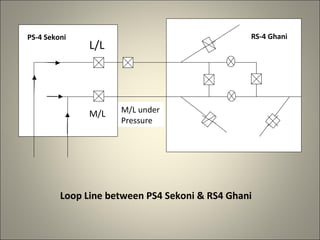

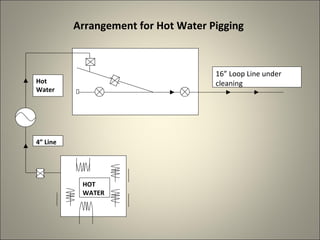

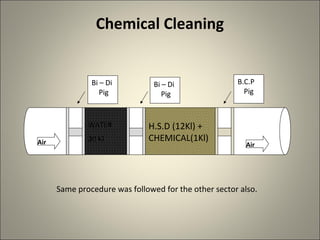

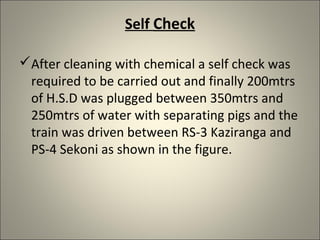

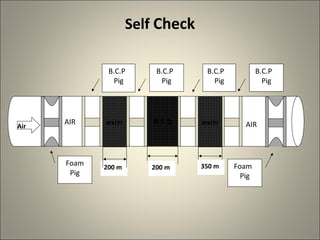

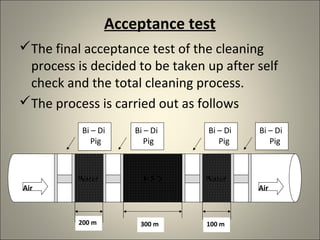

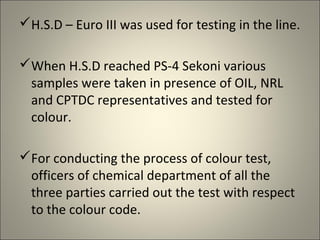

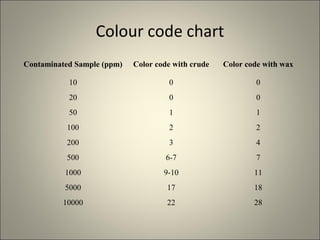

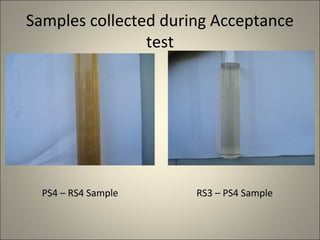

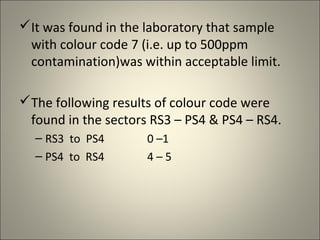

The document describes the de-waxing and cleaning process of a 212km long 16" loop line to prepare it for pumping products. A piece of land was rented and equipment like compressors, pumps, and boilers were used. The process involved pigging the line with different pigs using crude oil, then sweeping crude oil out with compressed air and water, followed by hot water pigging and chemical cleaning. Over 66 pigging operations were conducted removing over 20,000kg of wax from the Kaziranga to Sekoni sector. A similar process was then conducted from Sekoni to Ghani removing less wax.