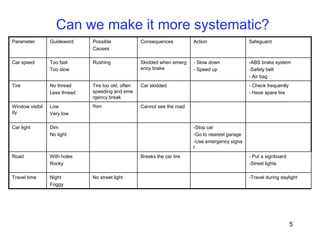

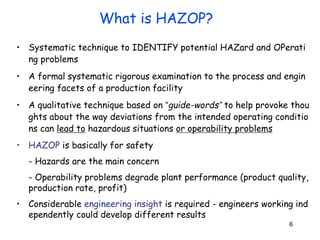

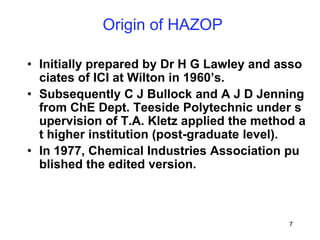

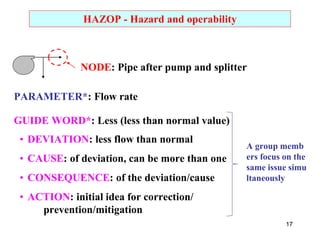

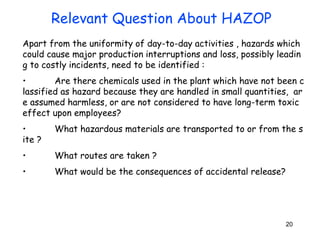

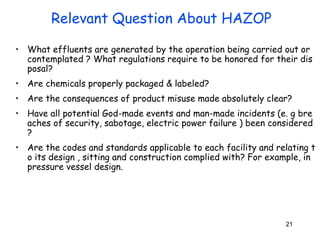

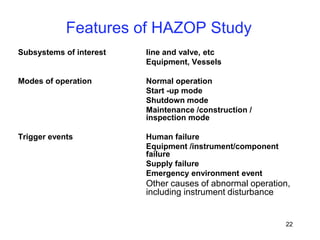

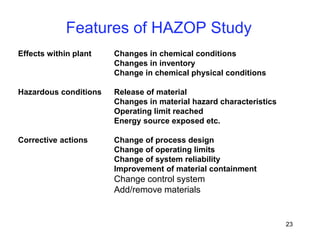

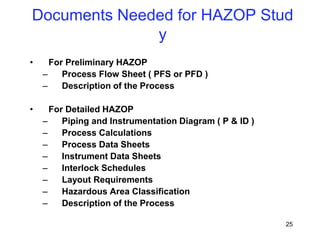

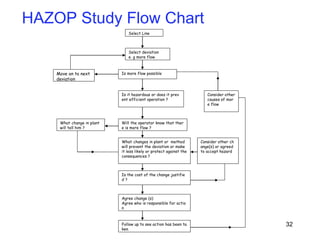

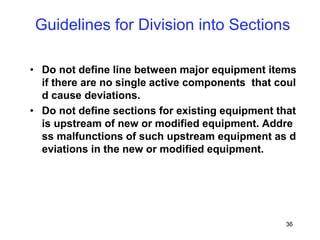

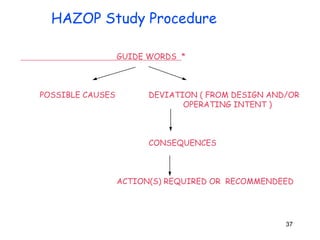

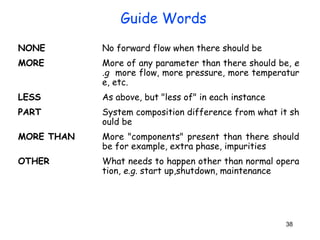

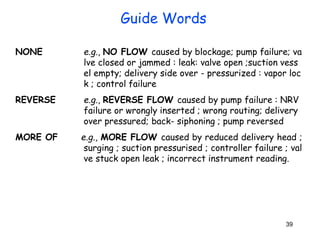

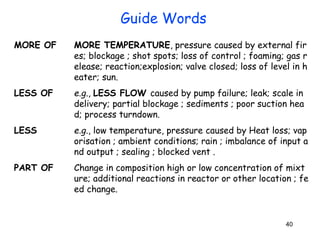

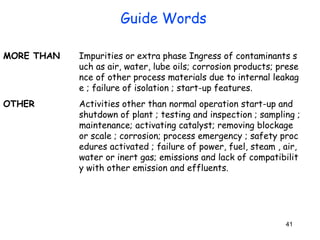

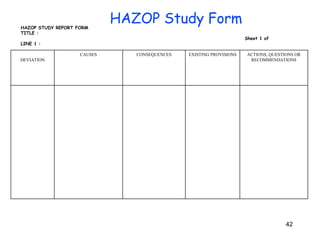

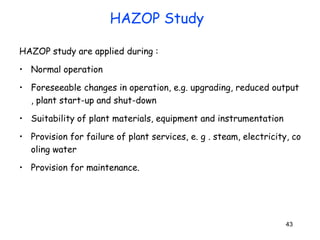

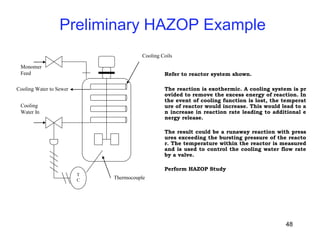

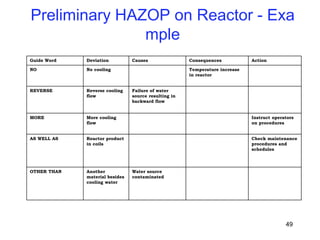

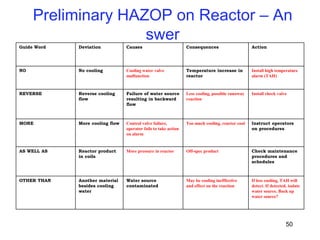

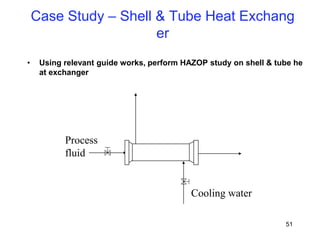

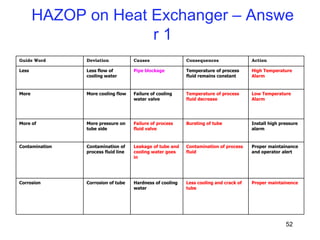

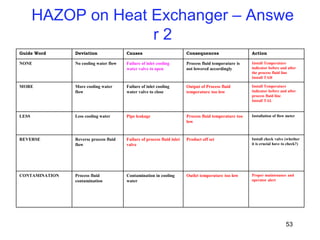

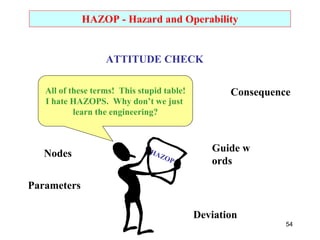

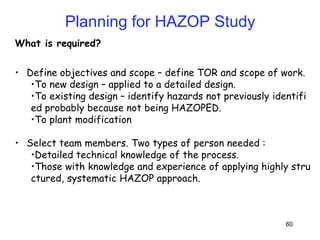

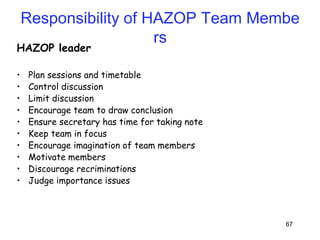

This document provides an overview of Hazard and Operability (HAZOP) studies. It begins with defining what a HAZOP study is, which is a systematic technique used to identify potential hazards and operating problems in industrial processes. The document then discusses the origins and development of HAZOP methodology. It provides details on the objectives, procedures, guidelines and key aspects of conducting a HAZOP study, including dividing the process into sections, using guide words to identify possible deviations, and documenting causes, consequences and recommended actions. Overall, the document serves as an introduction to HAZOP studies, covering their fundamental principles and approaches.