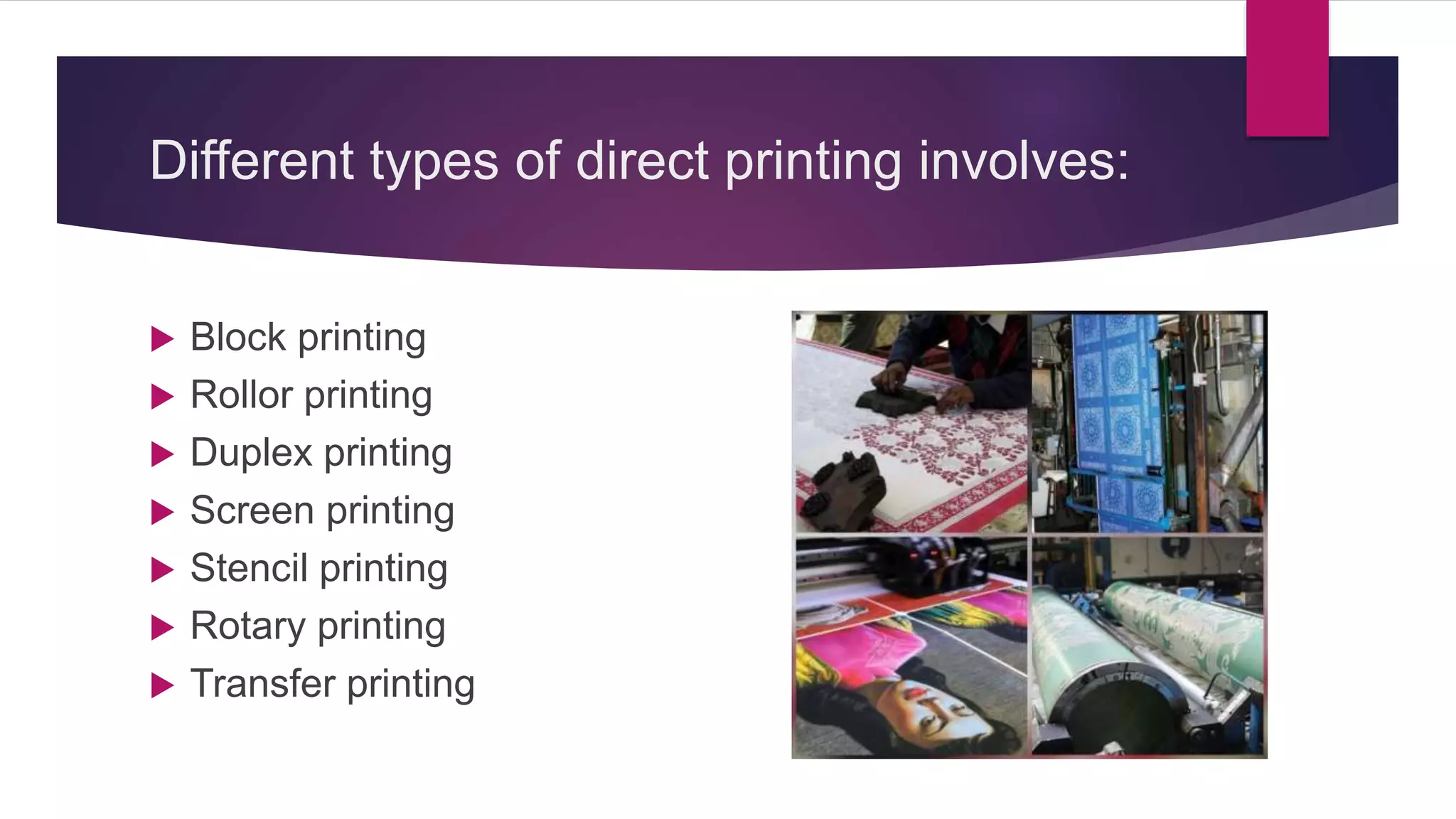

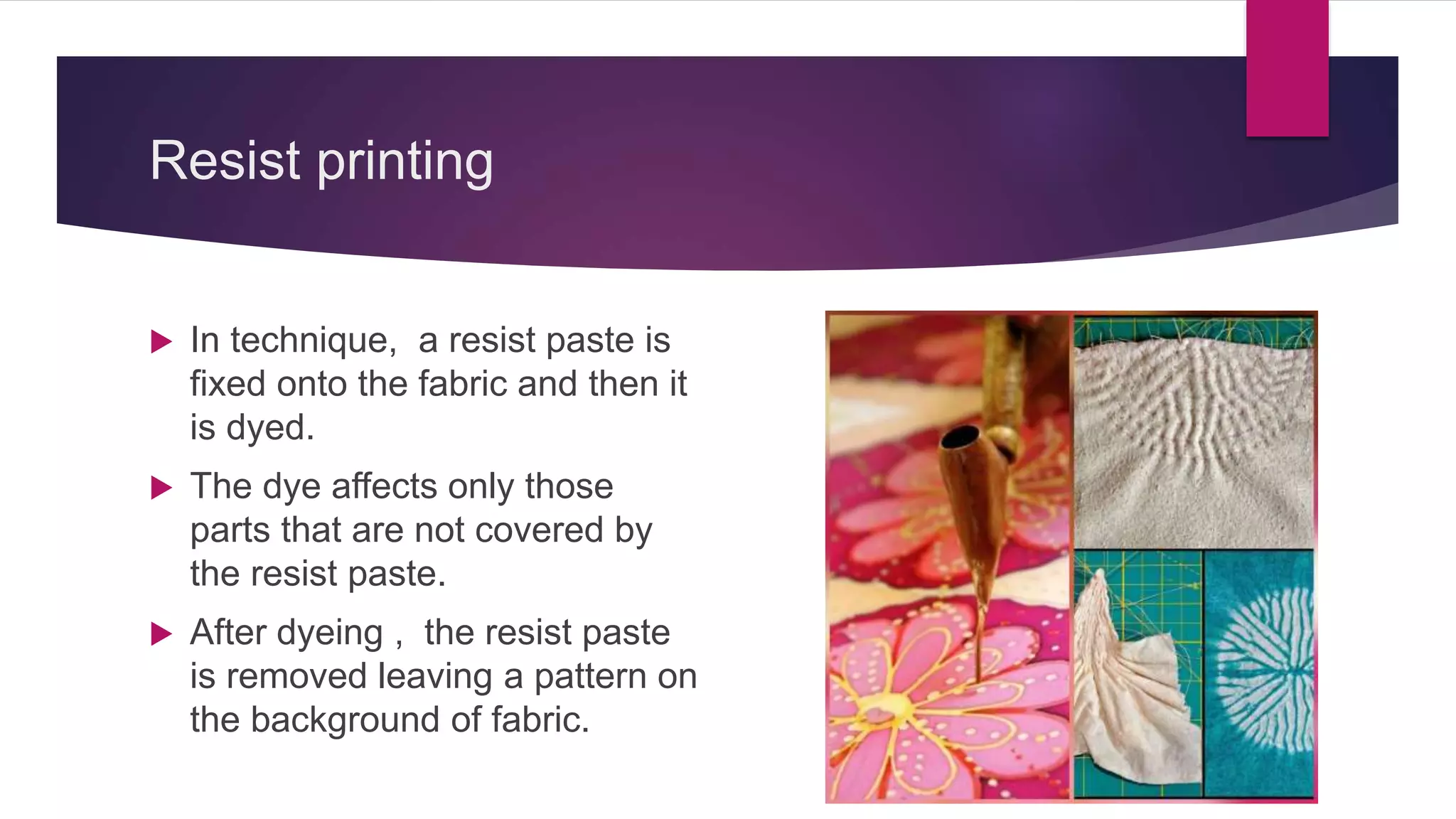

Direct printing is the most common method of applying color patterns to fabric. It involves applying dye directly to the fabric in paste form using block printing, screen printing, or roller printing. Discharge printing applies color to the entire fabric first and then removes color in certain areas to create a pattern. Resist printing involves applying a paste that resists dye to the fabric before dyeing it, so the pattern areas are not colored.