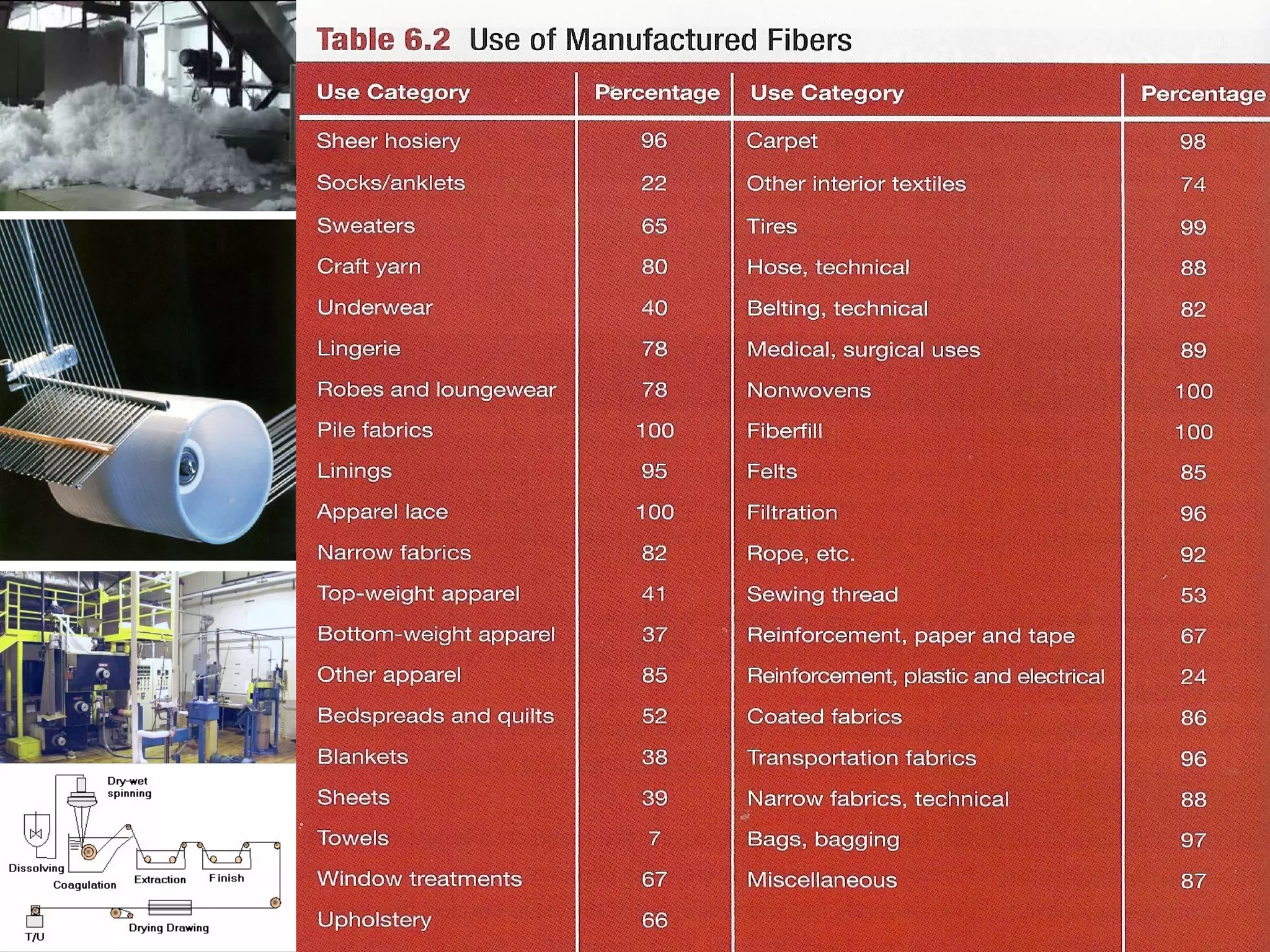

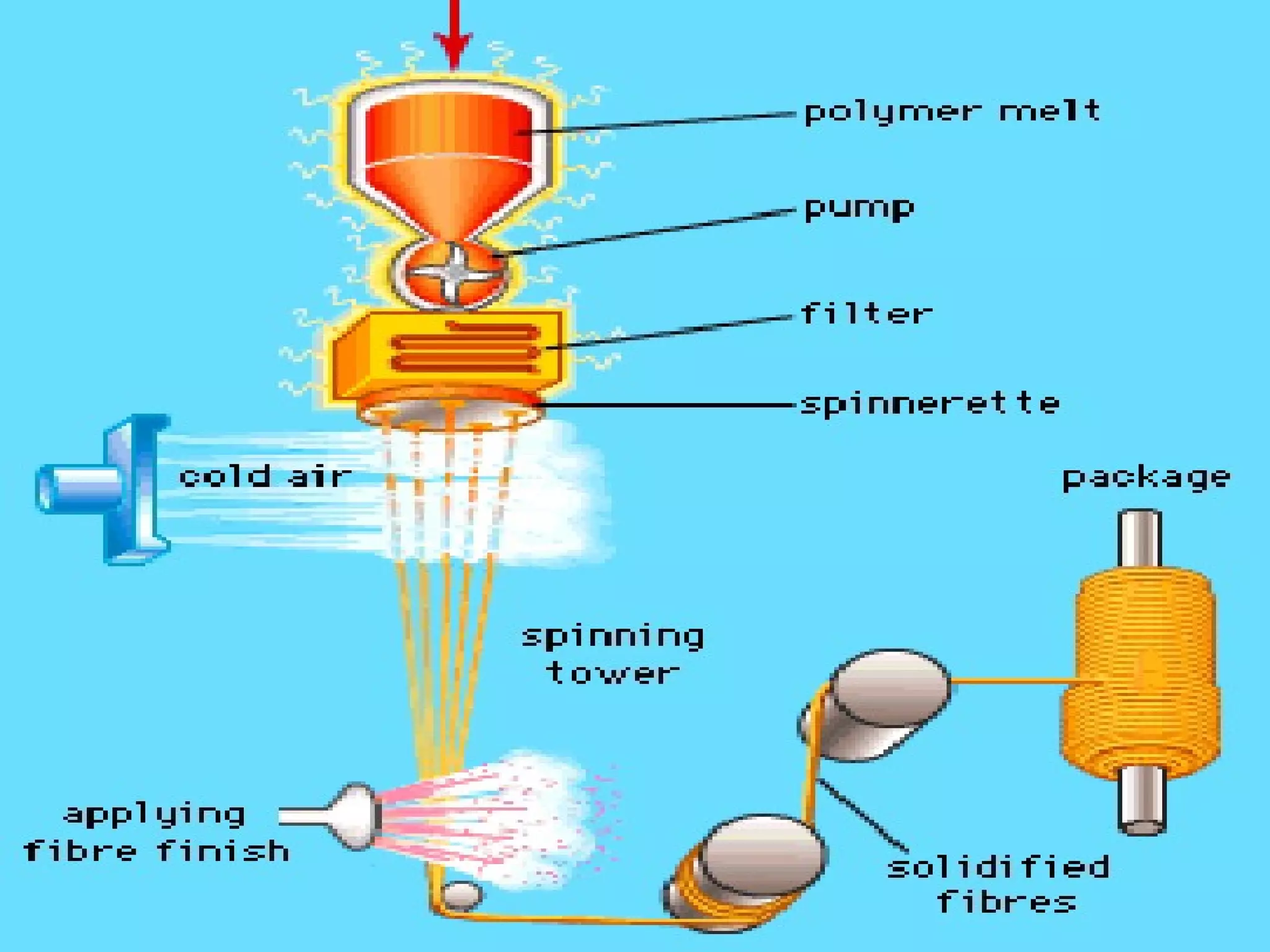

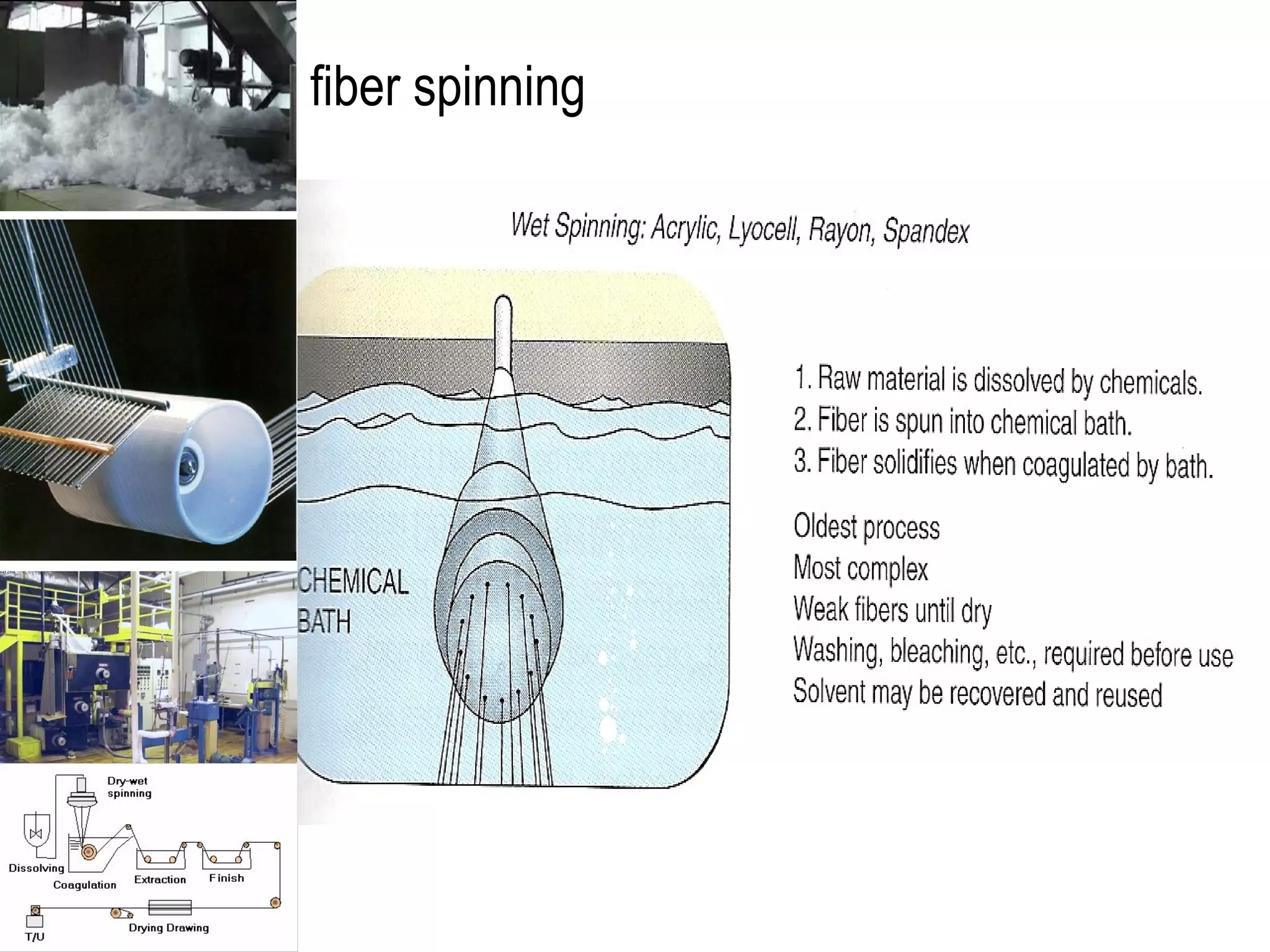

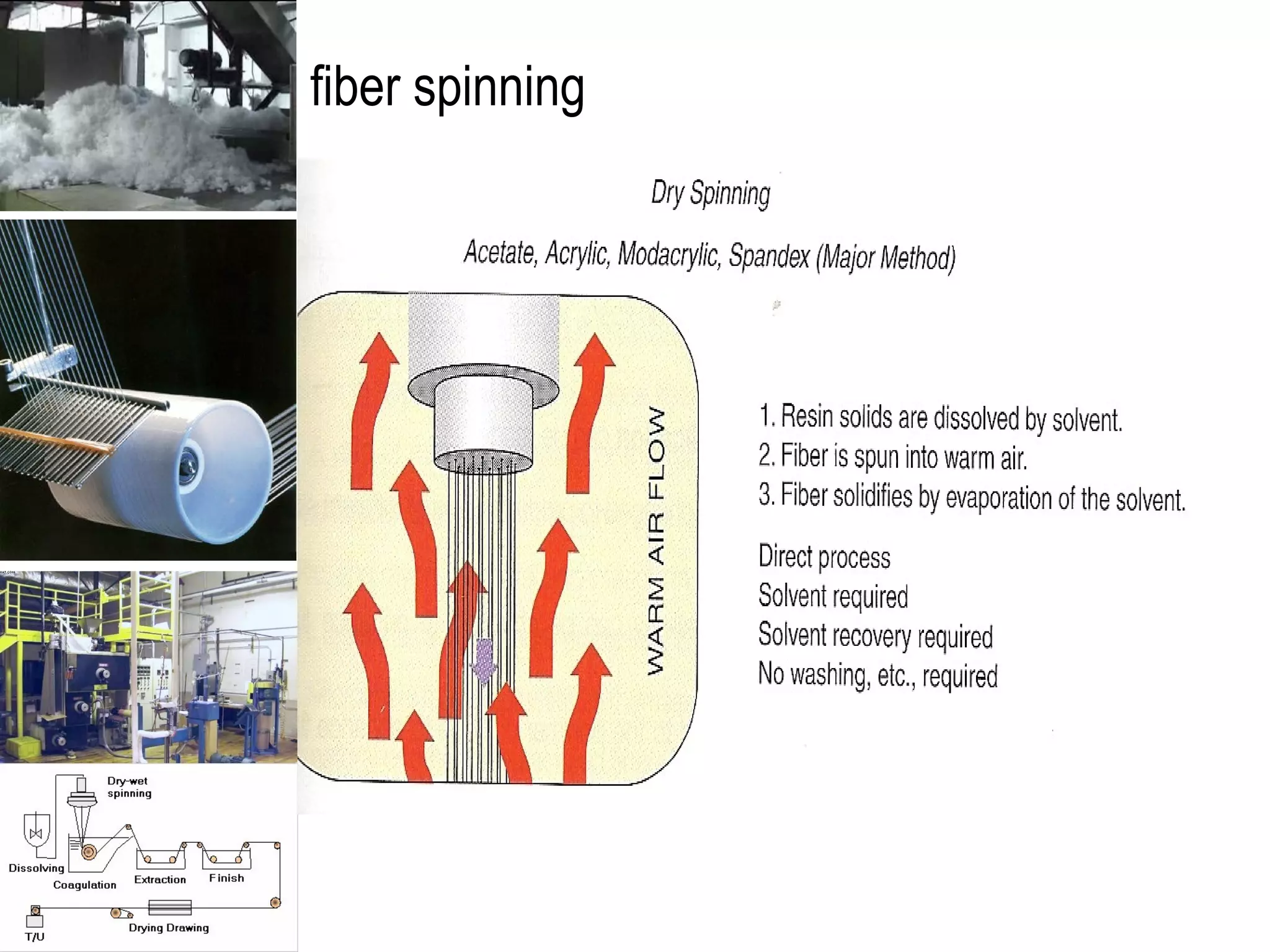

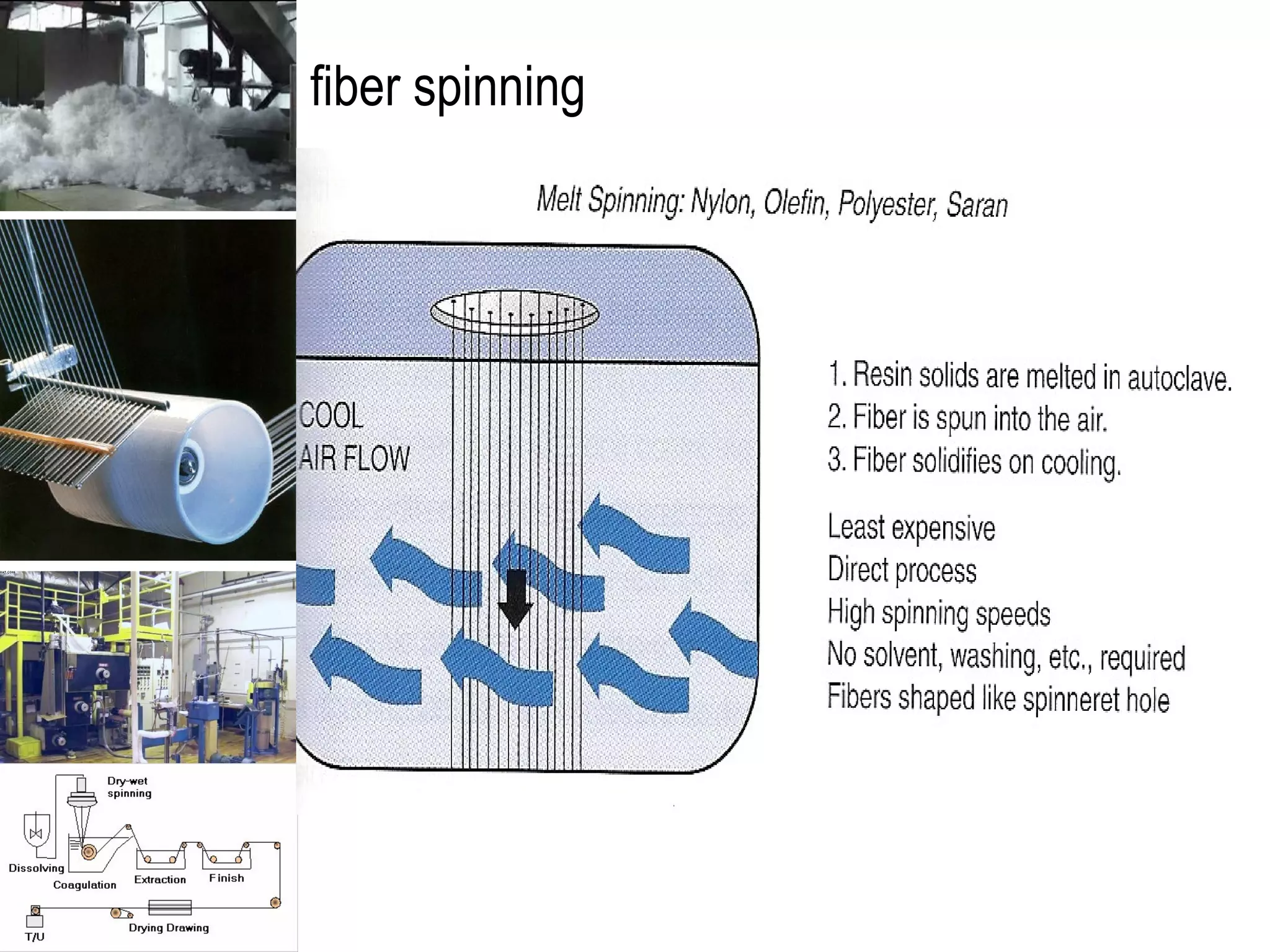

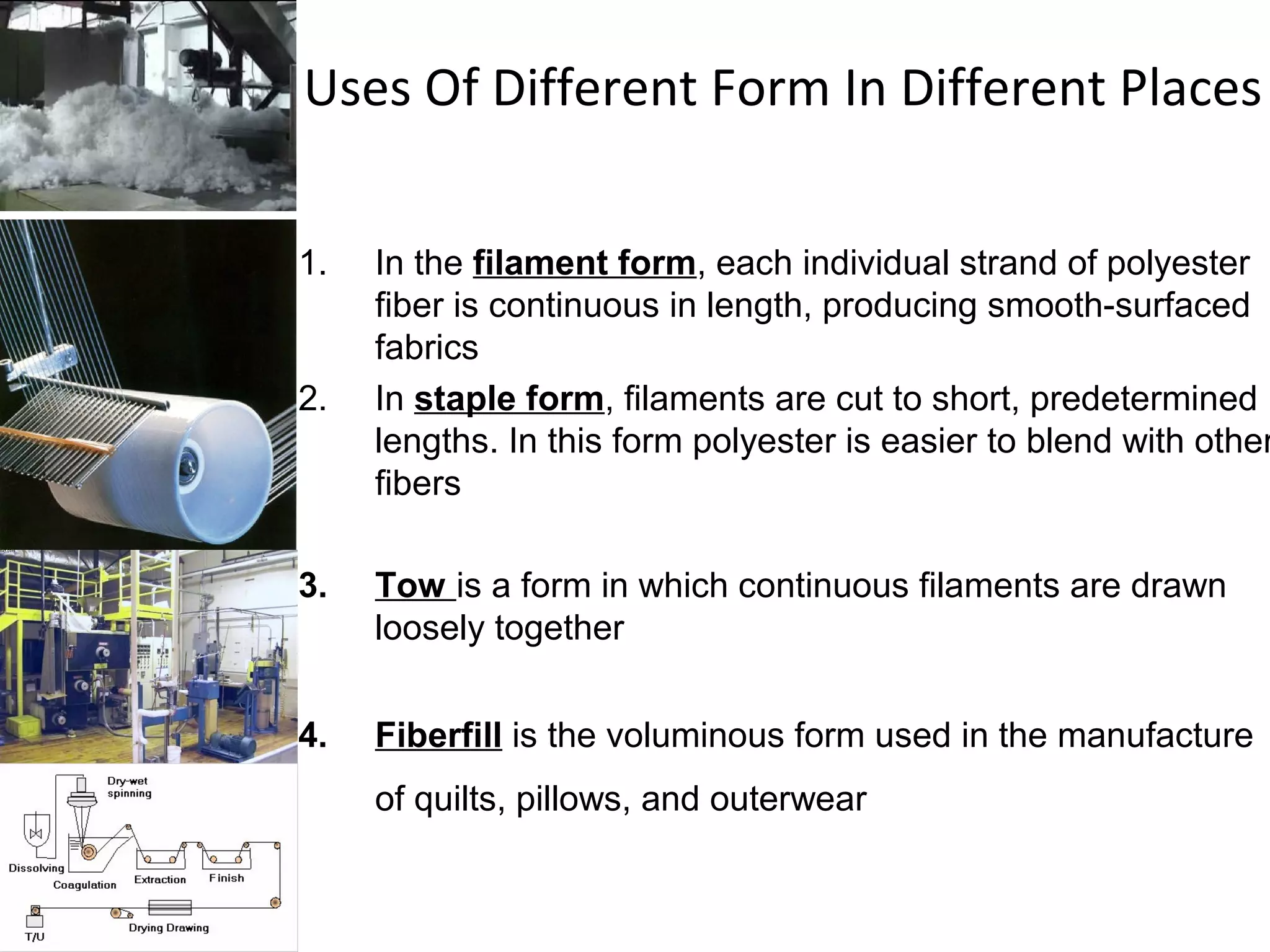

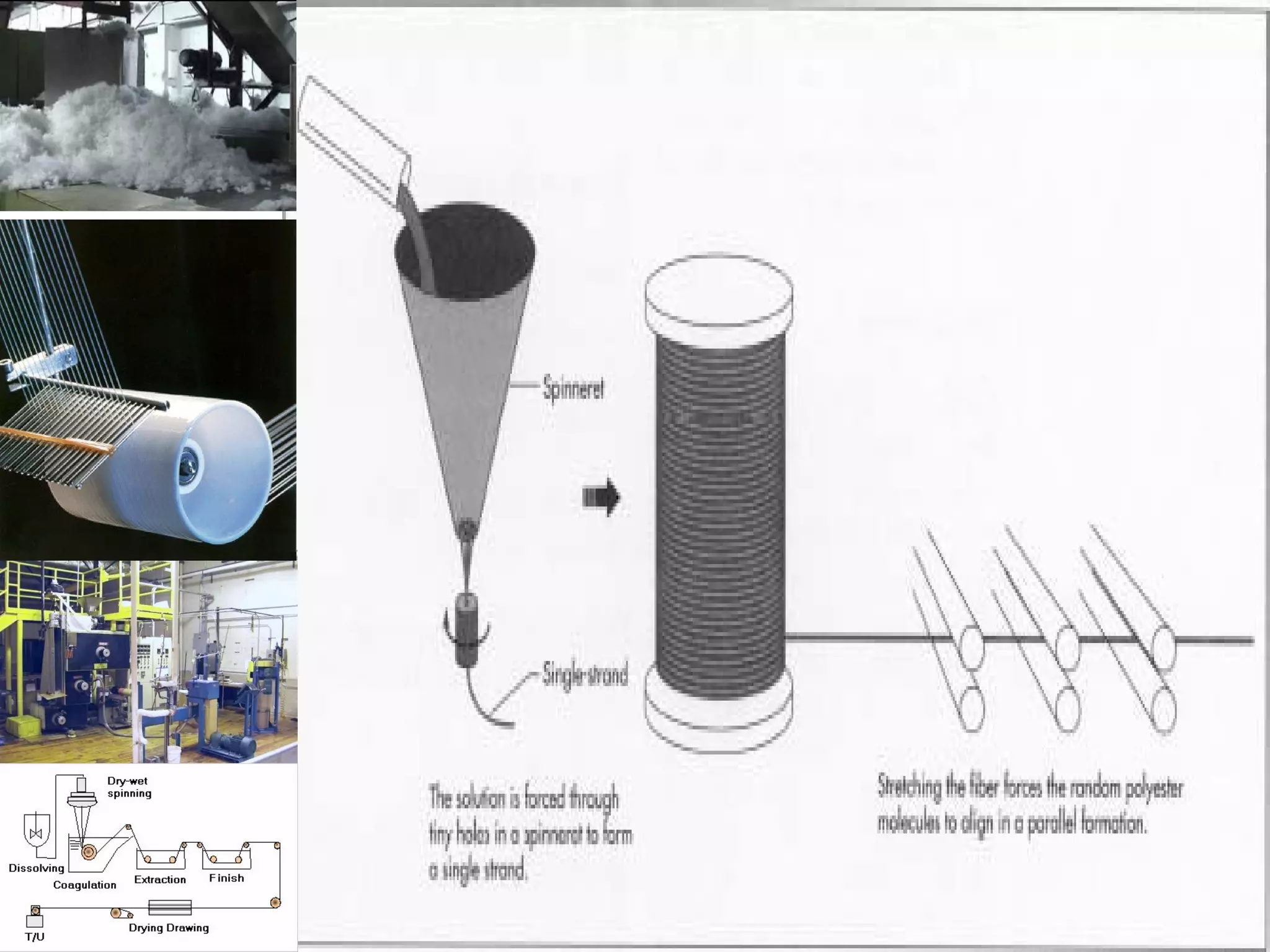

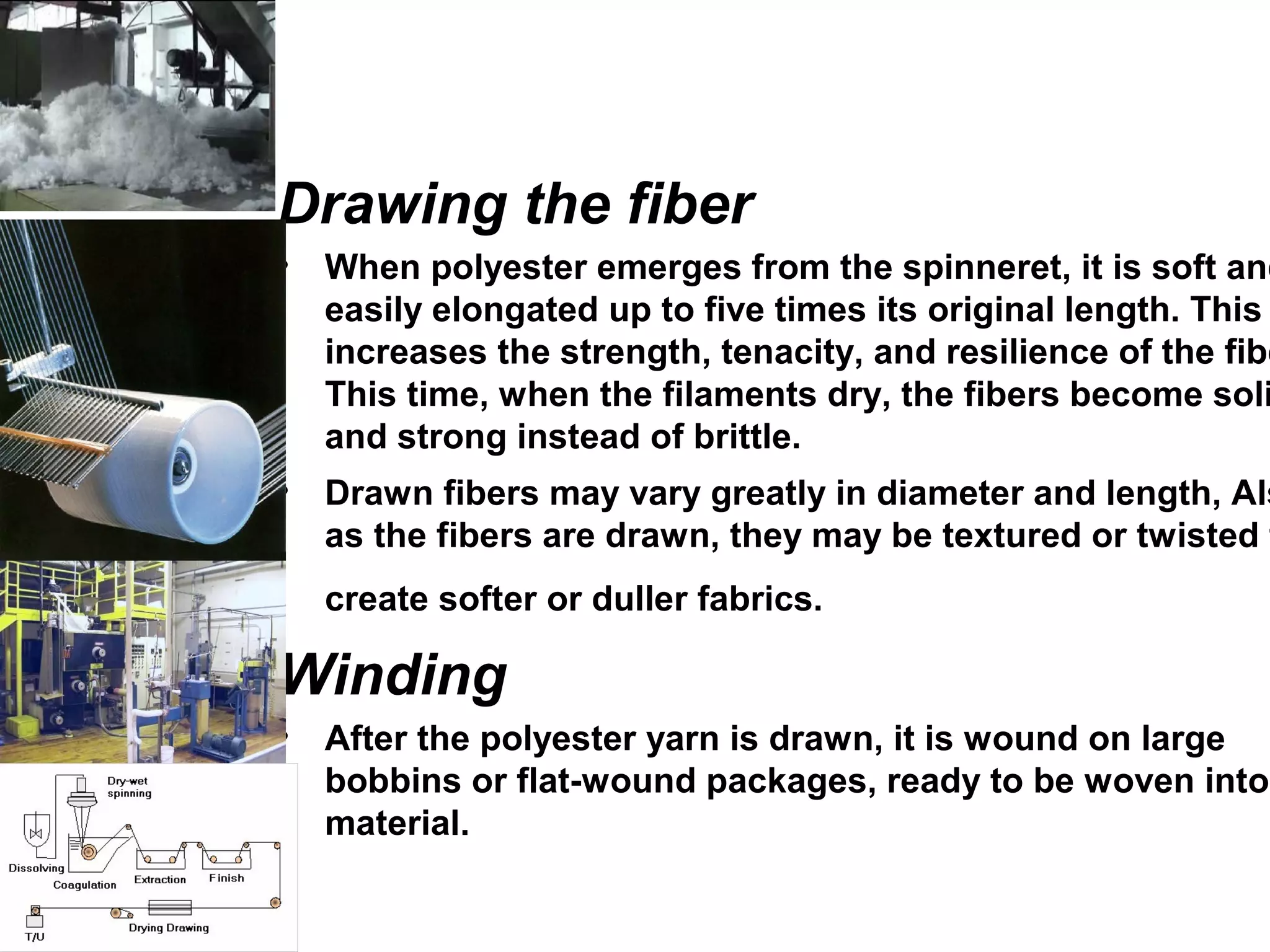

The document discusses the fiber manufacturing process. There are two types of manufactured fibers: regenerated and synthetic. The fiber spinning process involves three main steps: 1) preparing a viscous dope or melt, 2) forcing the dope or melt through a spinneret to form fibers, and 3) solidifying the fibers through coagulation, evaporation or cooling. Polyester is one of the most widely used synthetic fibers and is made through polymerization, drying, melt spinning, drawing the fibers, and winding. Its properties include durability, wrinkle resistance, and versatility.