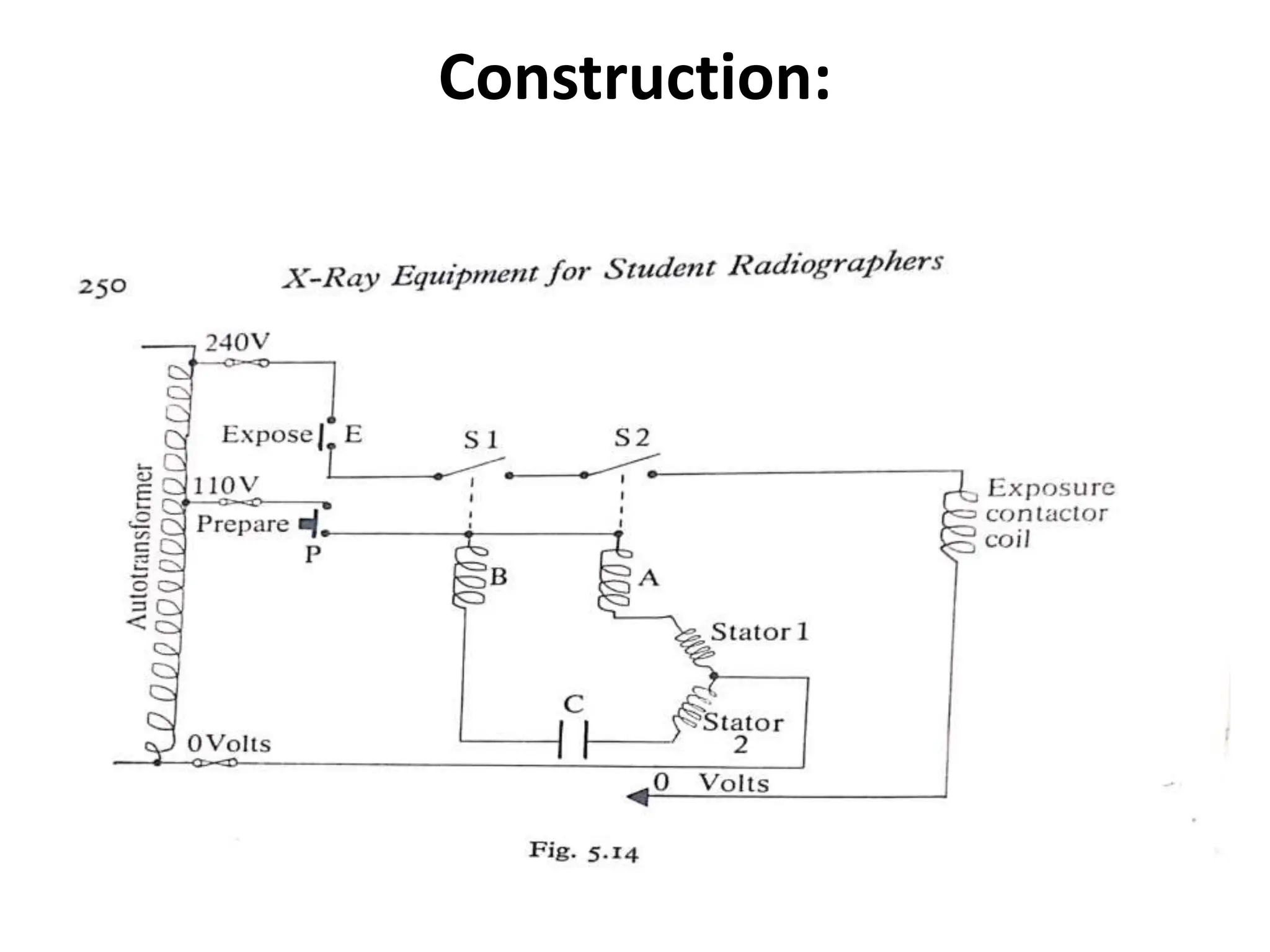

This document discusses factors that affect the useful life of an X-ray tube and how to extend it. It identifies key considerations like design, manufacturing quality, correct installation, careful handling, suitable tube selection for the intended use, and good radiographic practices like avoiding unnecessary high currents. It also describes common faults in X-ray tubes over time like changes to the glass envelope, anode wear, and filament failure. Finally, it explains the purpose and functioning of interlocking circuits to protect the tube from overloading.