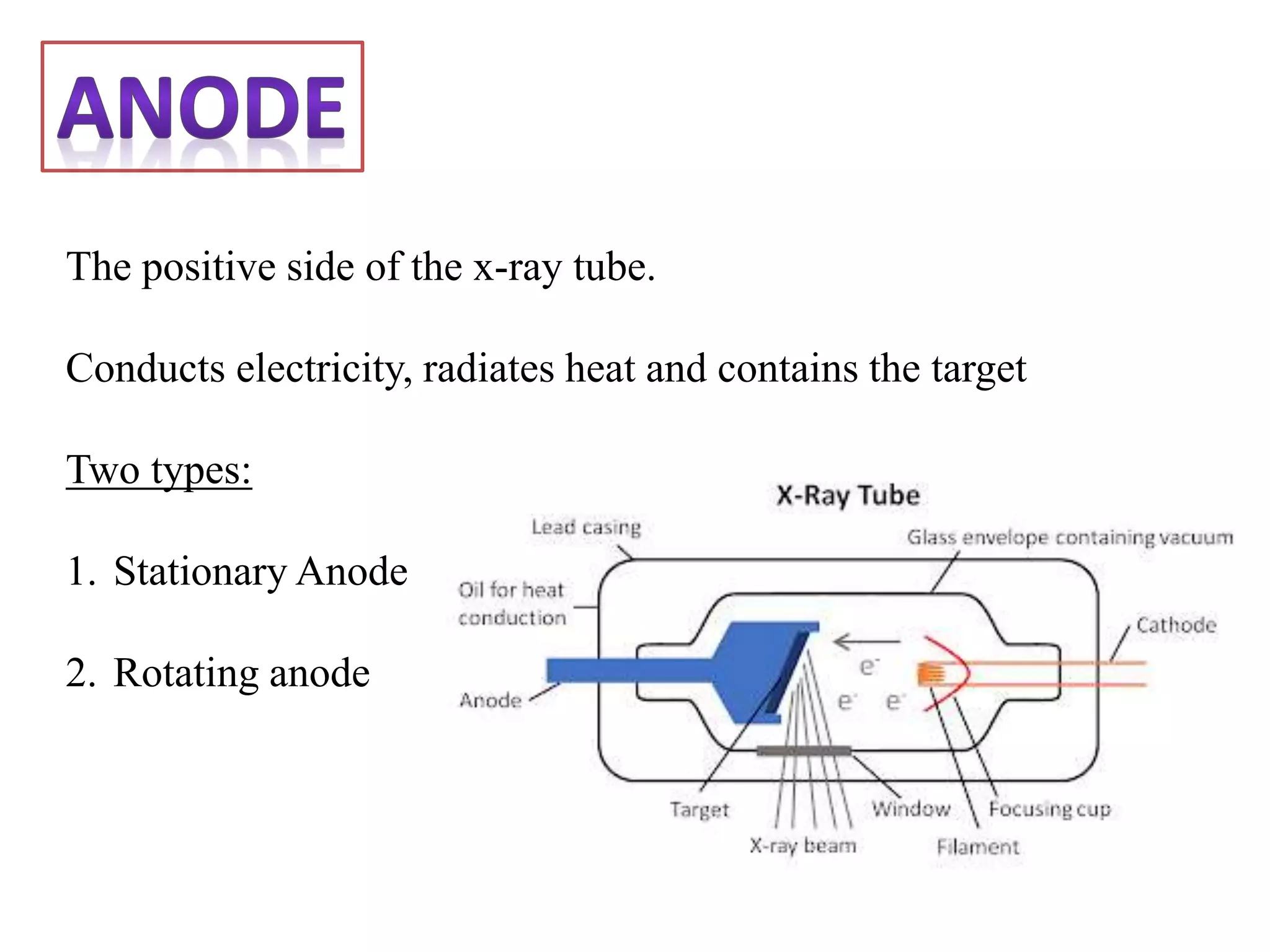

1. An x-ray tube converts electrical energy into x-radiation and heat through a process where electrons from the cathode target the anode, releasing photons.

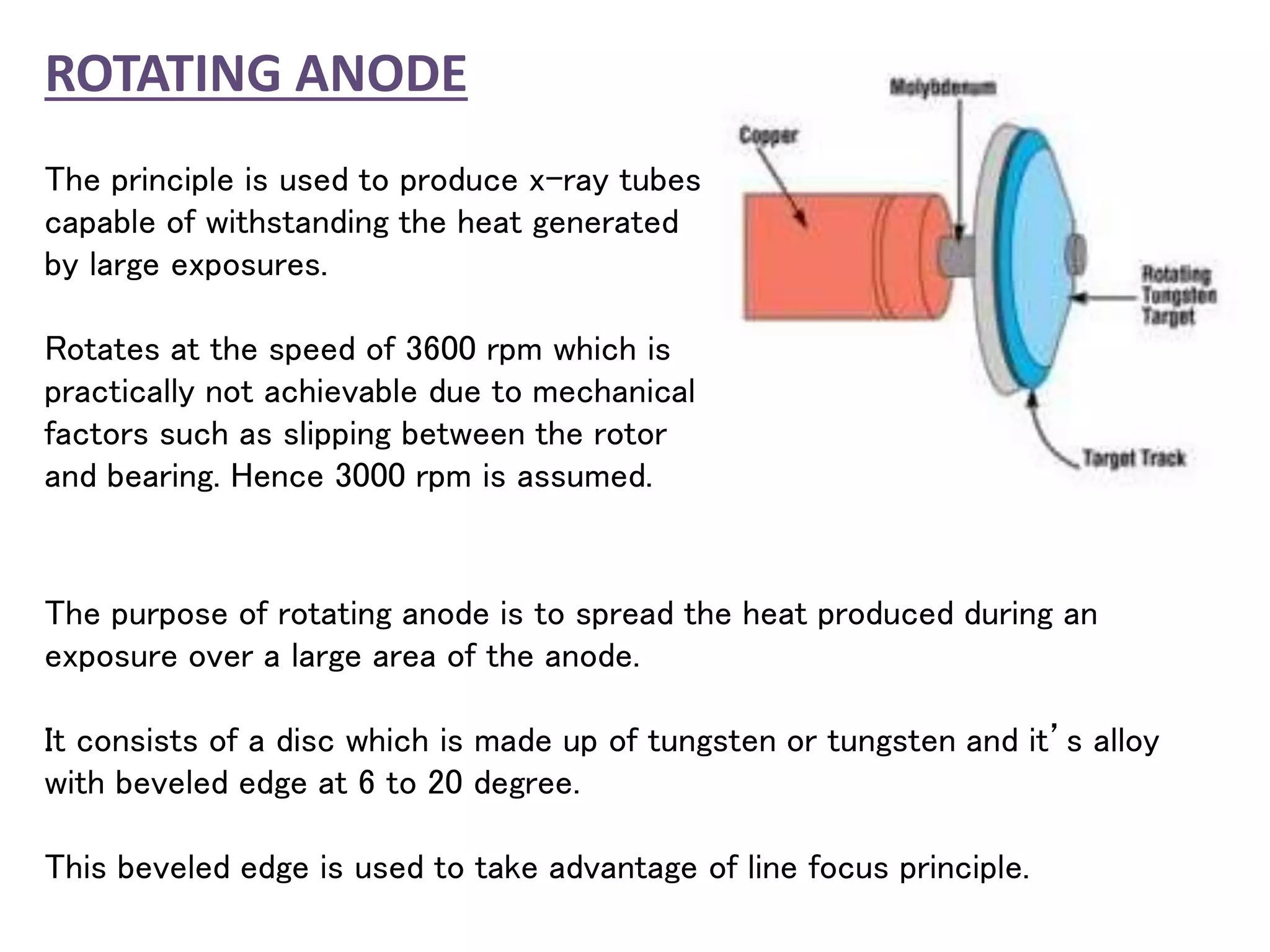

2. The principal components of an x-ray tube are the cathode, which emits electrons, and the anode, which acts as the target. In rotating anode tubes, the anode rotates to dissipate heat during exposures.

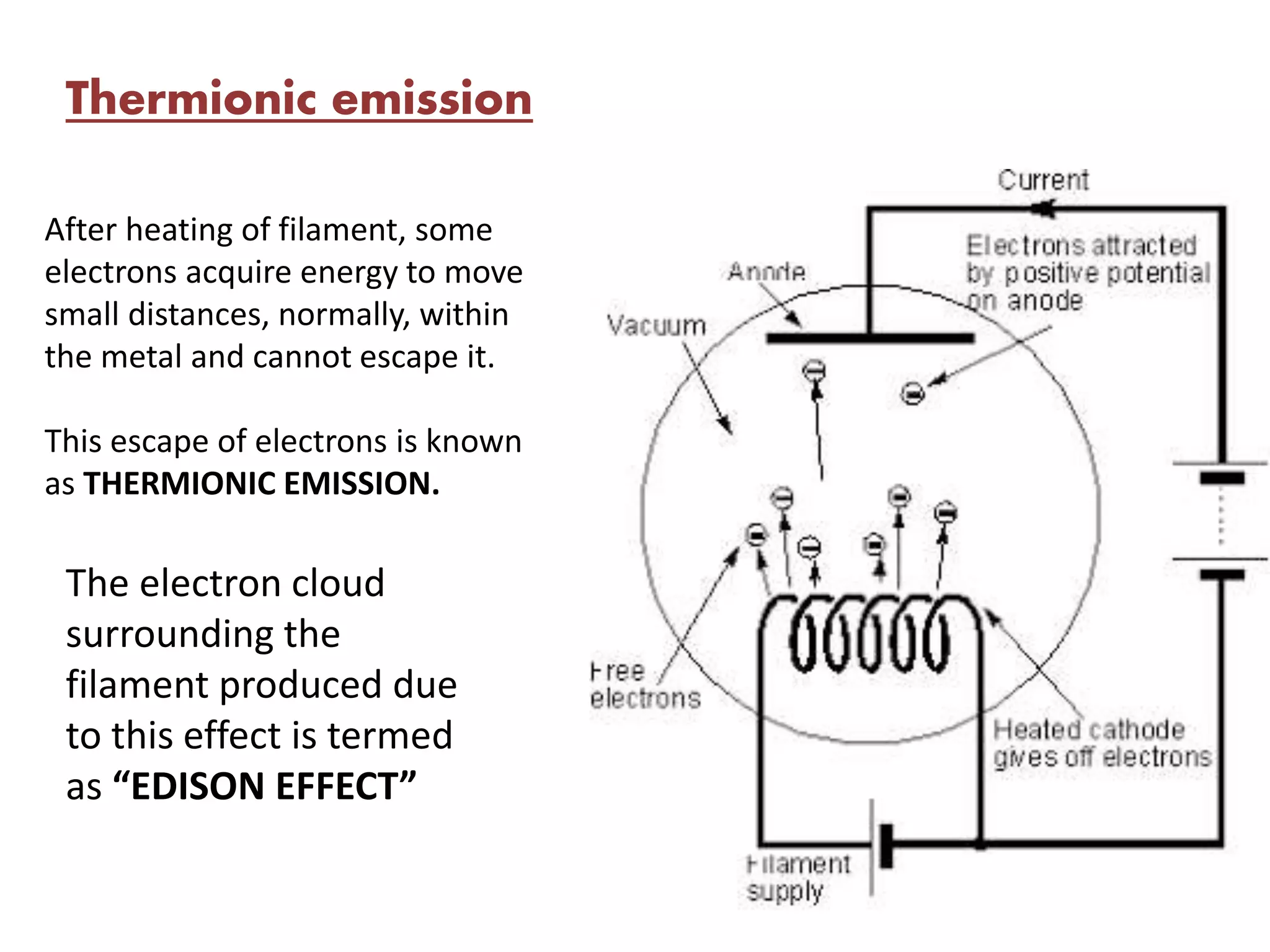

3. Tungsten is commonly used for the filament and target due to its high melting point and ability to efficiently produce x-rays. The filament is heated through thermionic emission to release electrons, while the target converts their impact into x-radiation.