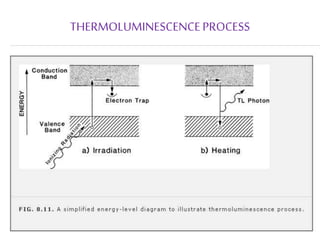

A thermoluminescent dosimeter (TLD) uses crystals that emit light when heated to measure radiation exposure. TLDs contain crystals, like calcium sulfate, that trap electrons when exposed to radiation. When the TLD is heated, the trapped electrons are released and emit light. The amount of light emitted corresponds to the amount of radiation absorbed. TLDs are commonly used as personal radiation badges to monitor worker exposure over time.