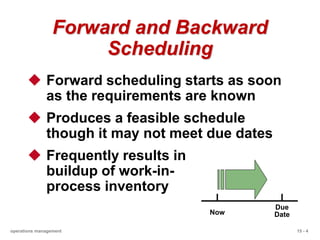

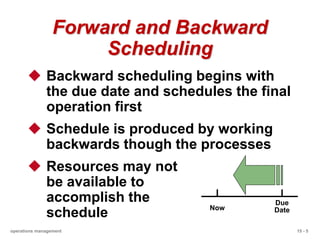

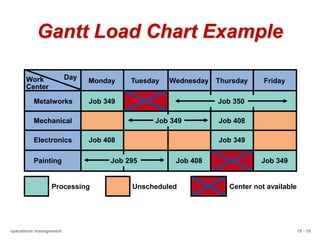

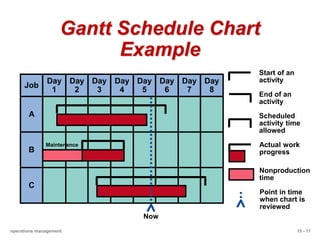

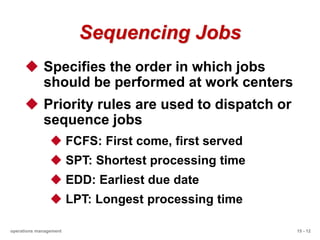

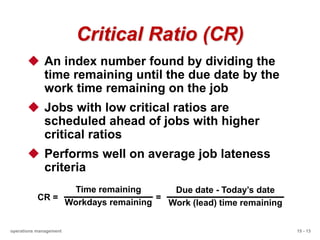

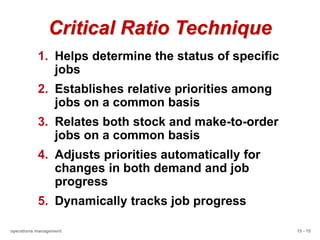

The document discusses short-term scheduling techniques in operations management. It describes forward and backward scheduling, and notes their advantages and disadvantages. Different criteria for scheduling are presented, including minimizing completion time and inventory. Gantt charts are introduced as a way to visualize scheduling and loading of jobs over time. Finally, sequencing rules like critical ratio are explained, which prioritize jobs based on factors like due date and processing time remaining.