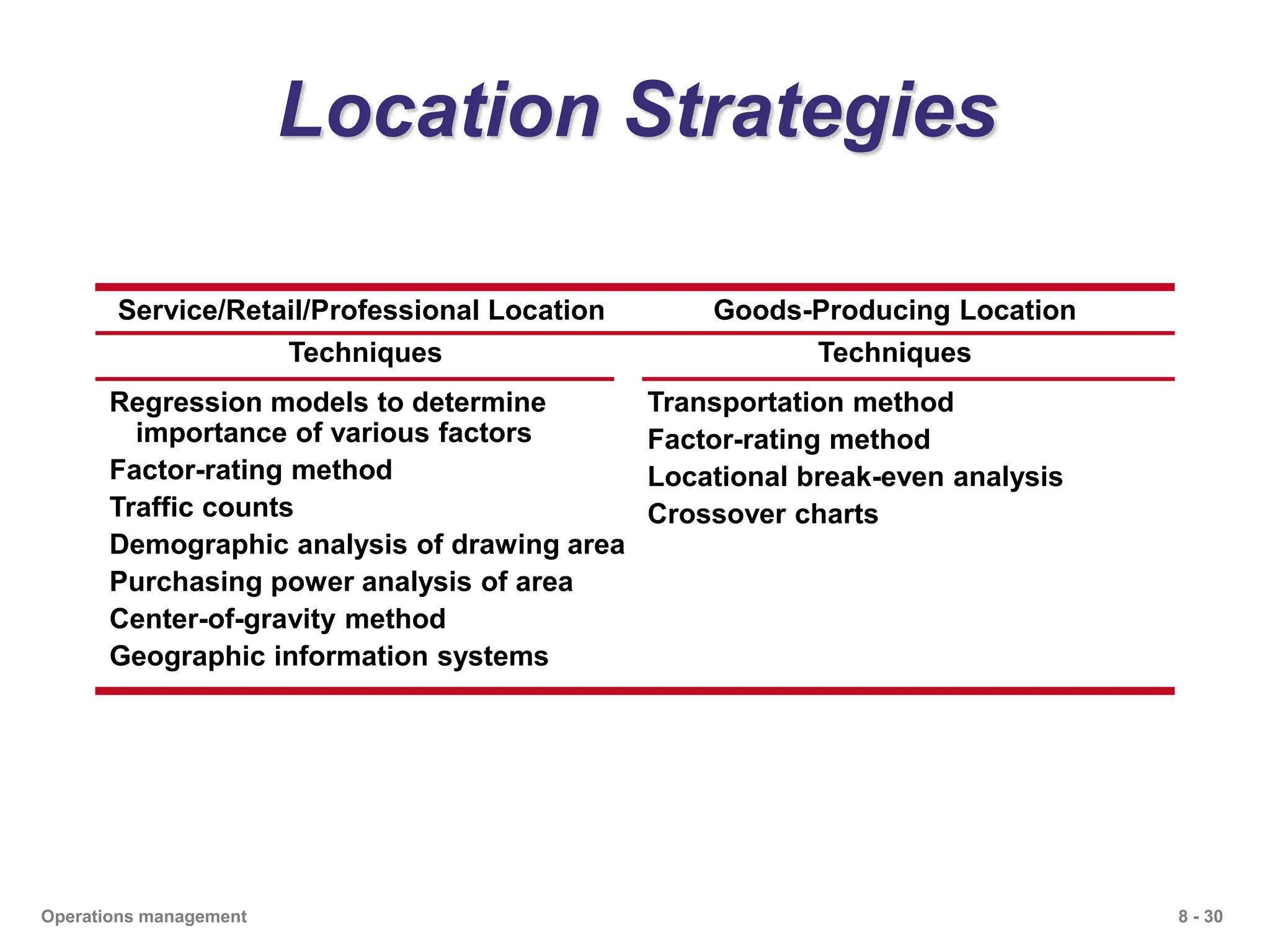

The document discusses factors that affect location decisions for facilities. It covers different strategies for location decisions depending on whether the focus is on costs for goods-producing locations or revenue for service/retail locations. Several methods for analyzing location options are presented, including factor-rating, locational break-even analysis, center-of-gravity, and transportation modeling. Intangible costs and future considerations are also important parts of the analysis. Geographic information systems can provide detailed data to inform the evaluation of potential locations.