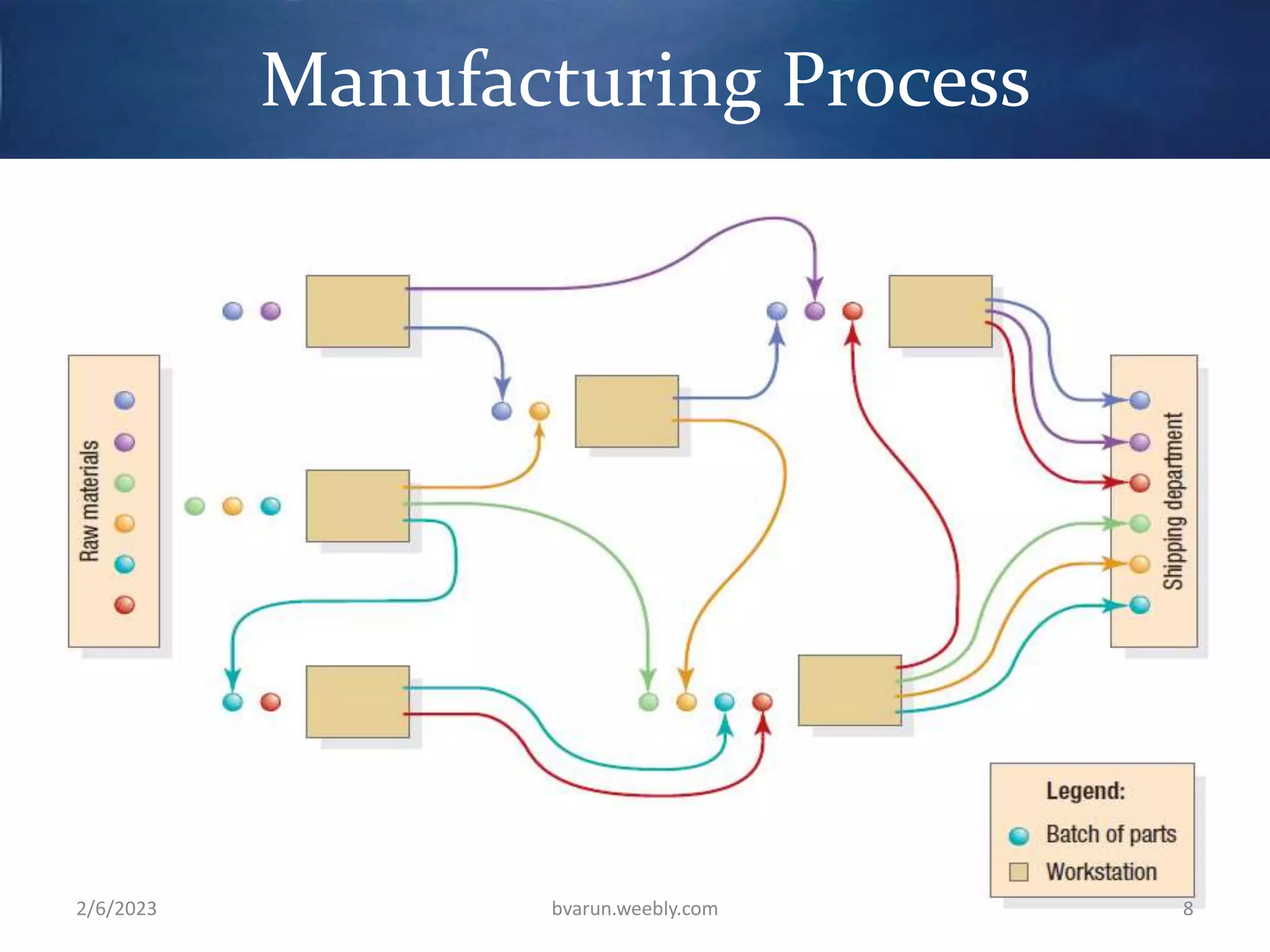

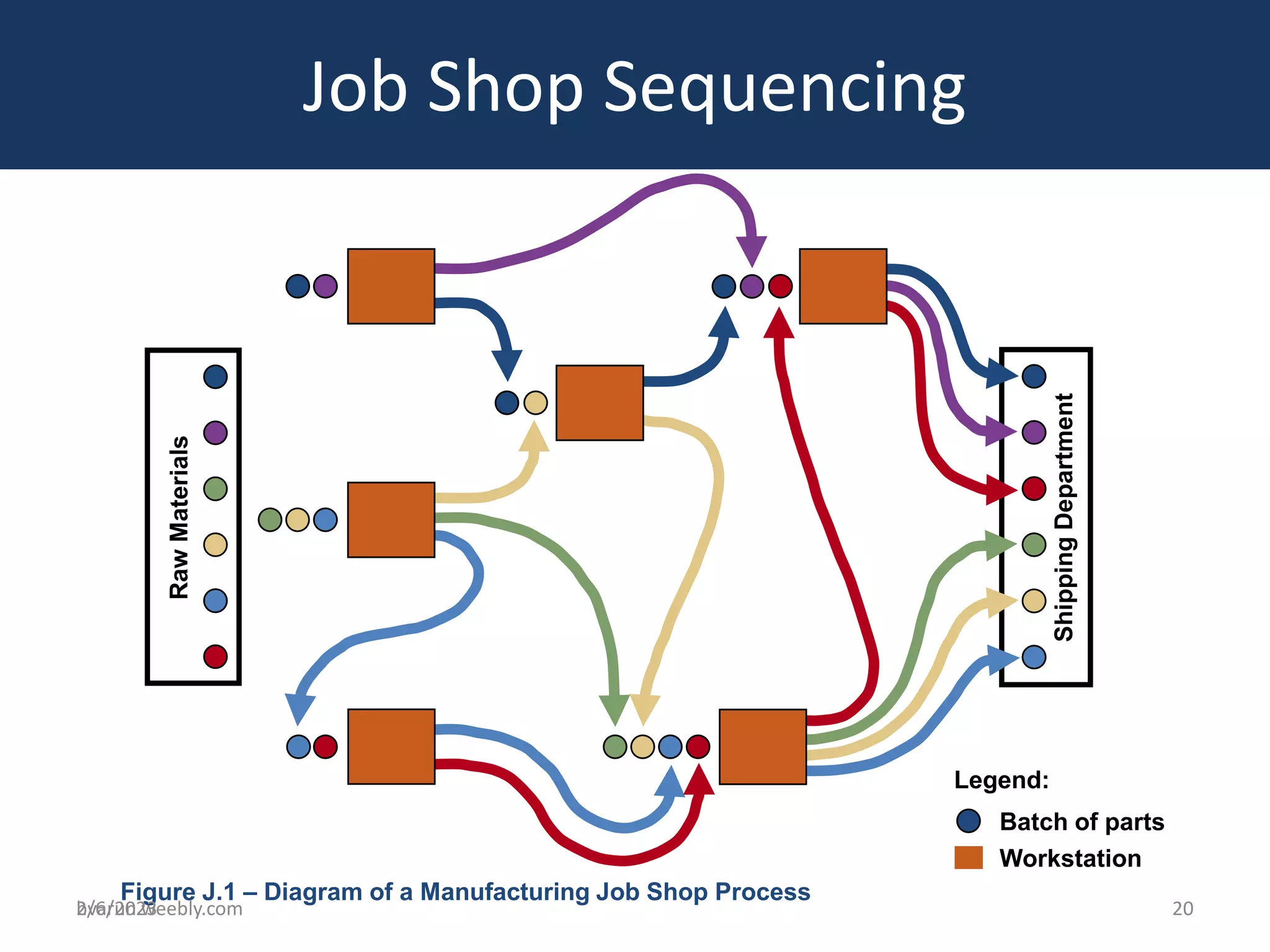

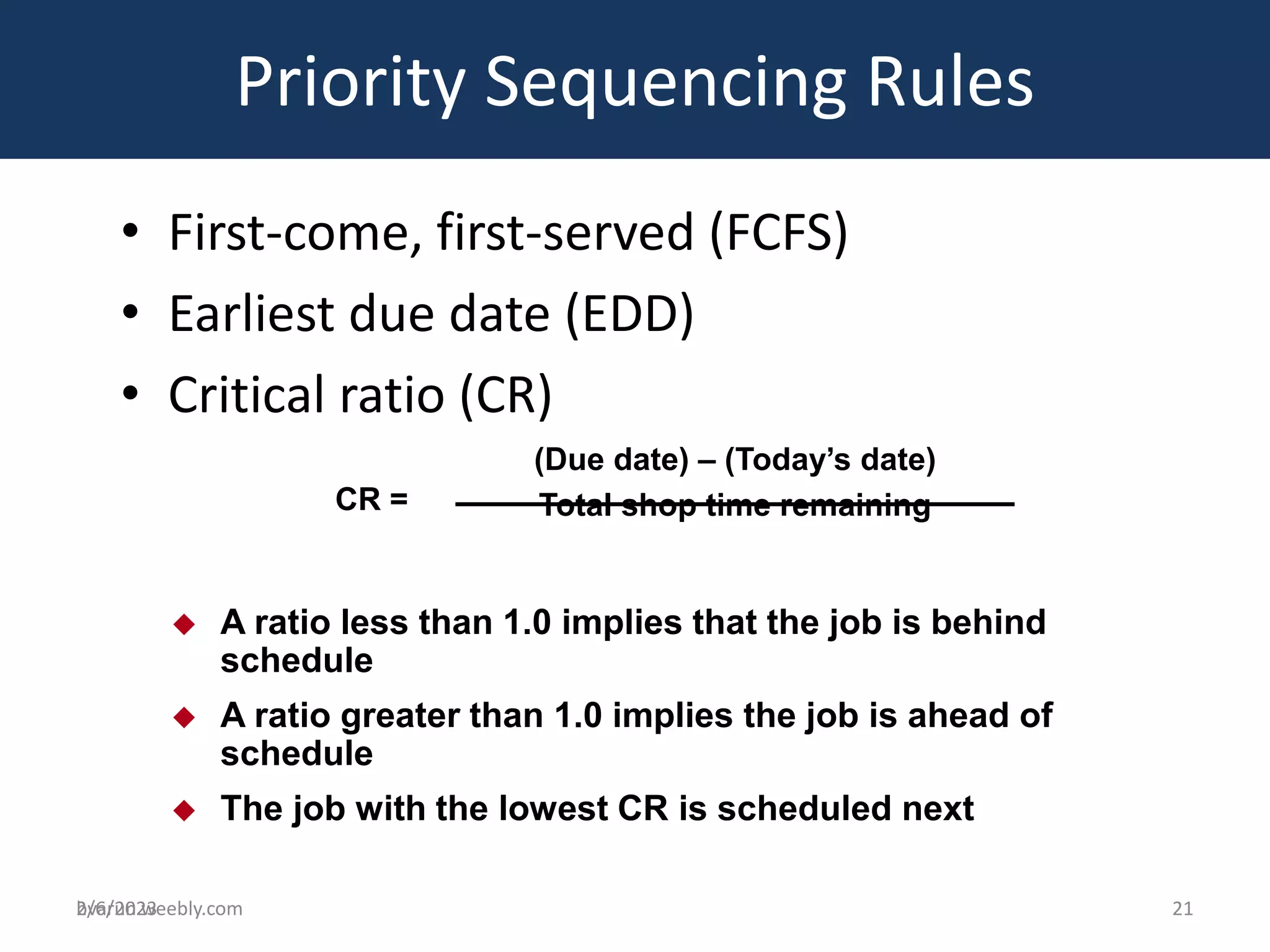

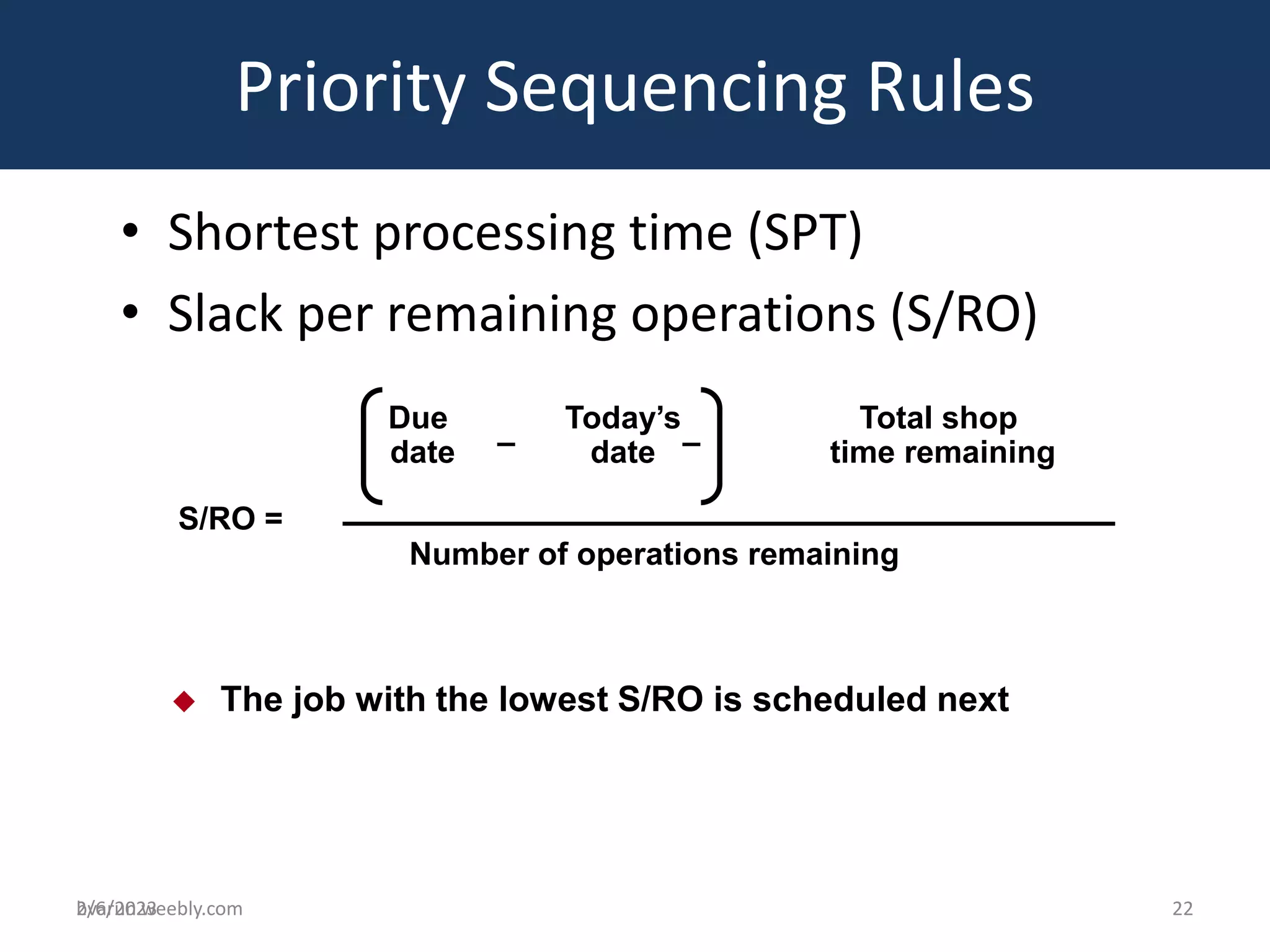

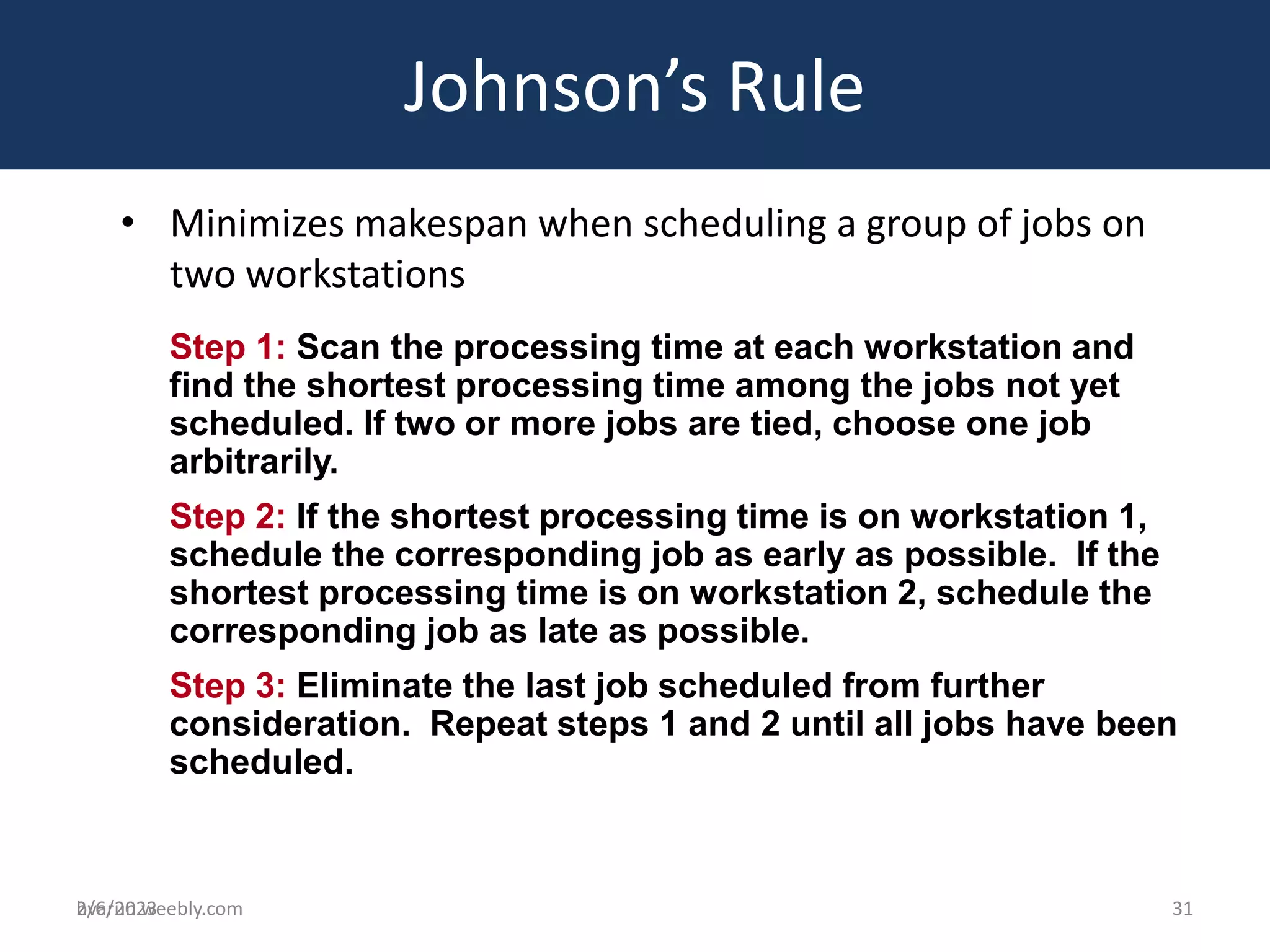

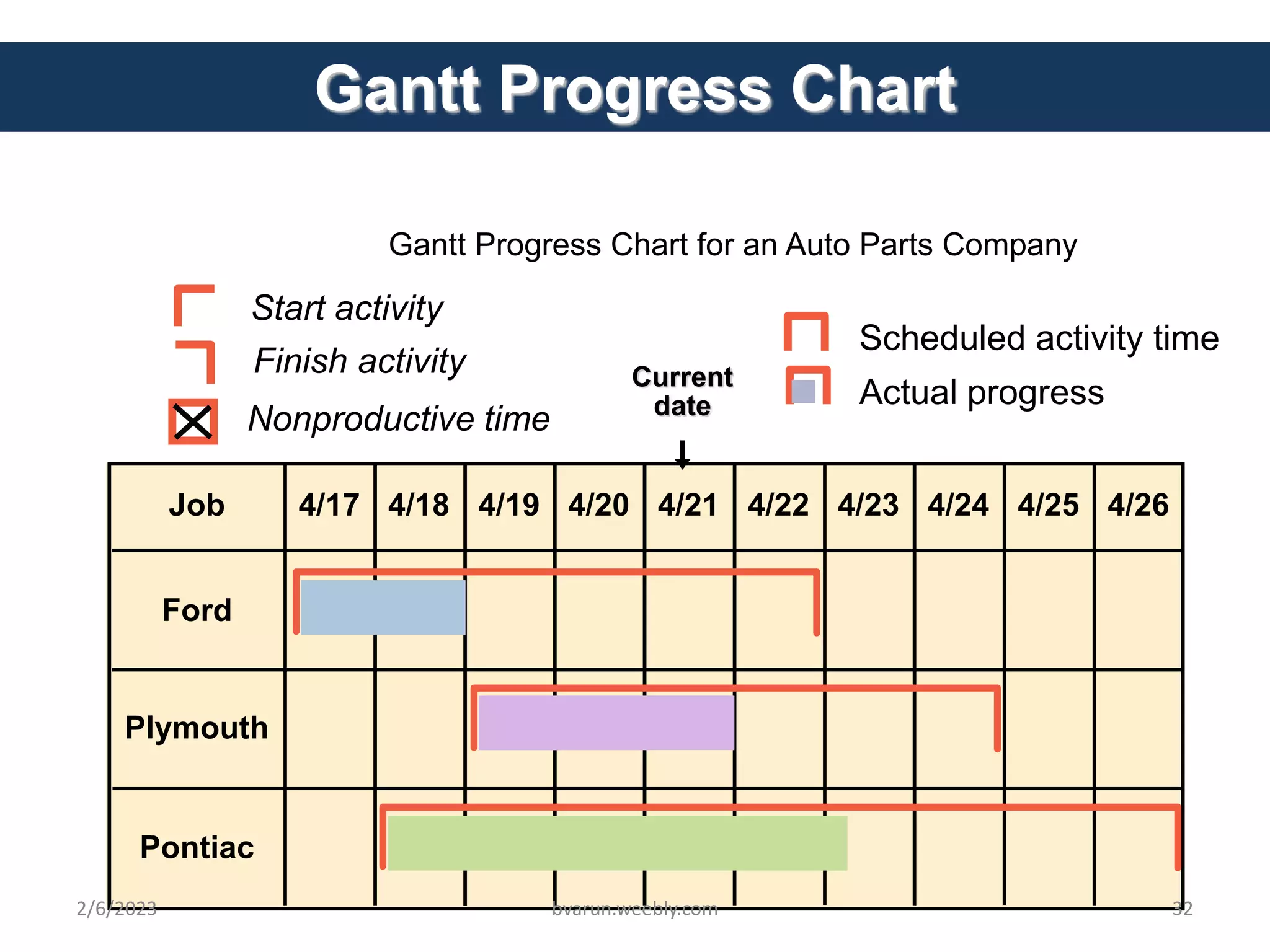

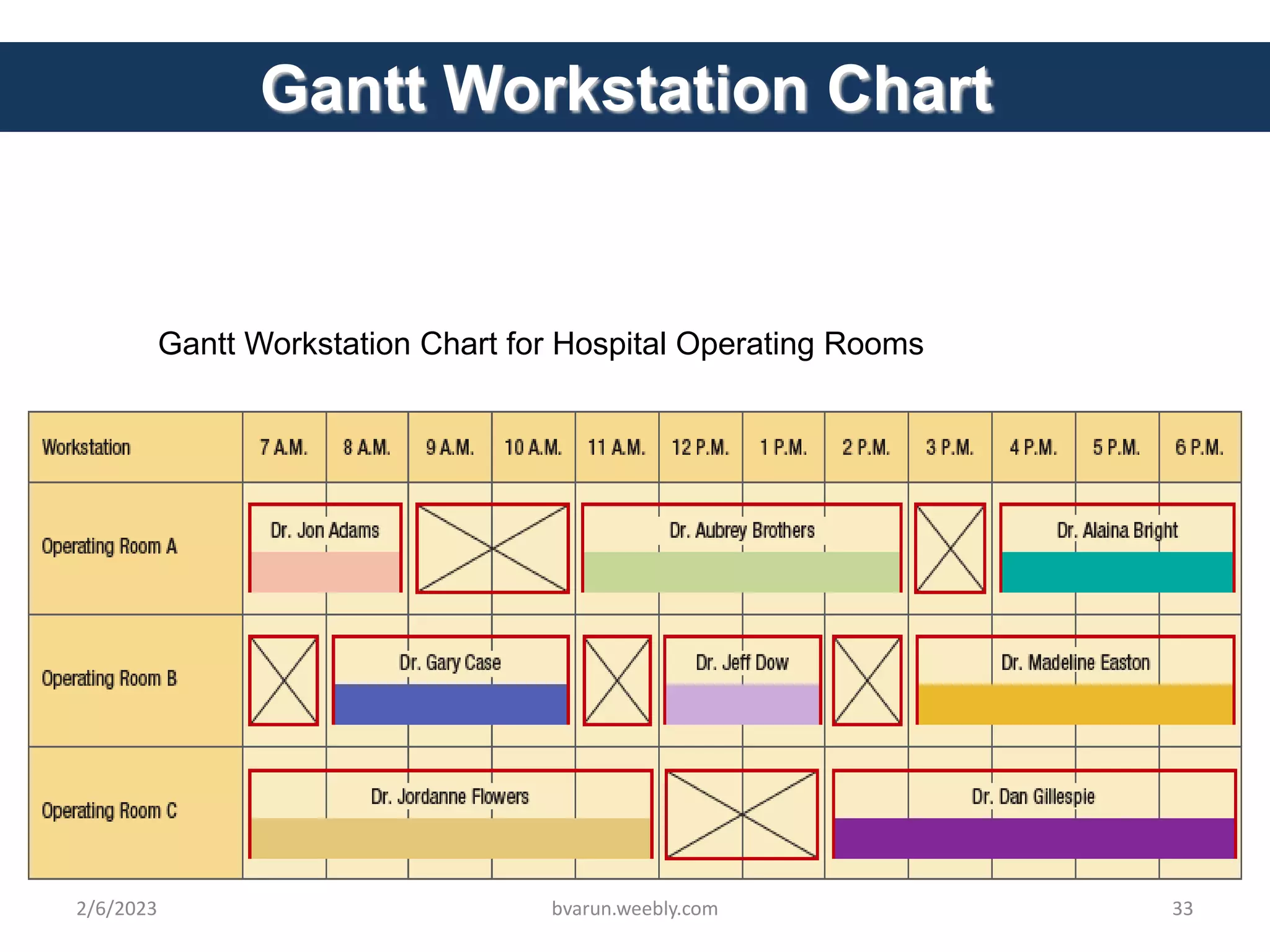

Operations scheduling is critical for meeting customer demands and inventory targets. It involves assigning jobs to work centers, determining start and completion times, allocating resources, and establishing task sequences. Effective scheduling balances performance metrics like flow time, inventory levels, and machine utilization. Priority rules are used to sequence jobs at multiple workstations, though determining the best rule can be complex due to interactions between processes. Gantt charts are useful tools for scheduling and tracking job and workstation progress.