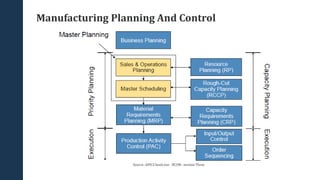

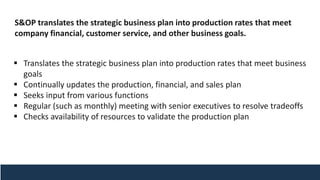

The document discusses master scheduling and related planning processes. It provides the following key points:

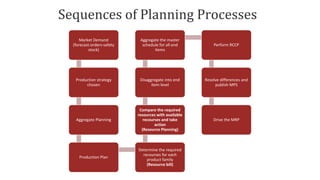

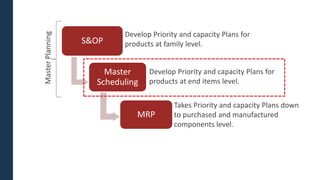

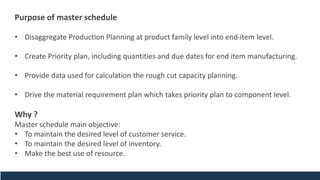

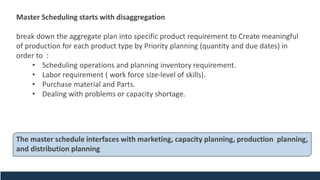

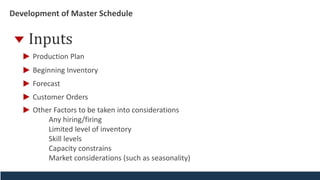

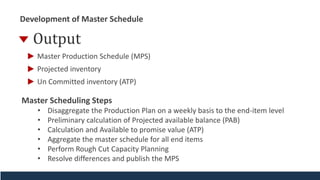

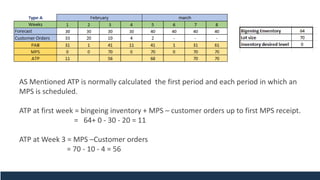

1. Master scheduling begins with disaggregating an aggregate production plan into specific product requirements and end-item level schedules. This includes assigning quantities and due dates.

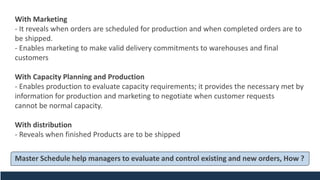

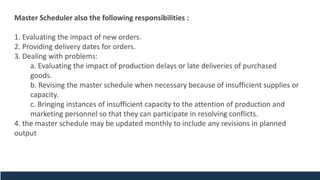

2. The master schedule coordinates production planning with other functions like marketing, capacity planning, and distribution. It shows the timing of end-item production and completed orders.

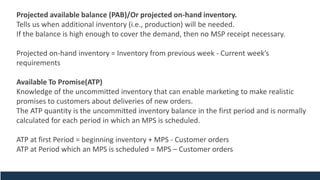

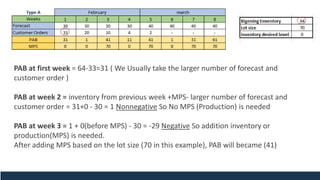

3. The process involves calculating projected inventory balances and available-to-promise values to evaluate order commitments and production needs. Rough cut capacity planning is also used to check resource feasibility.