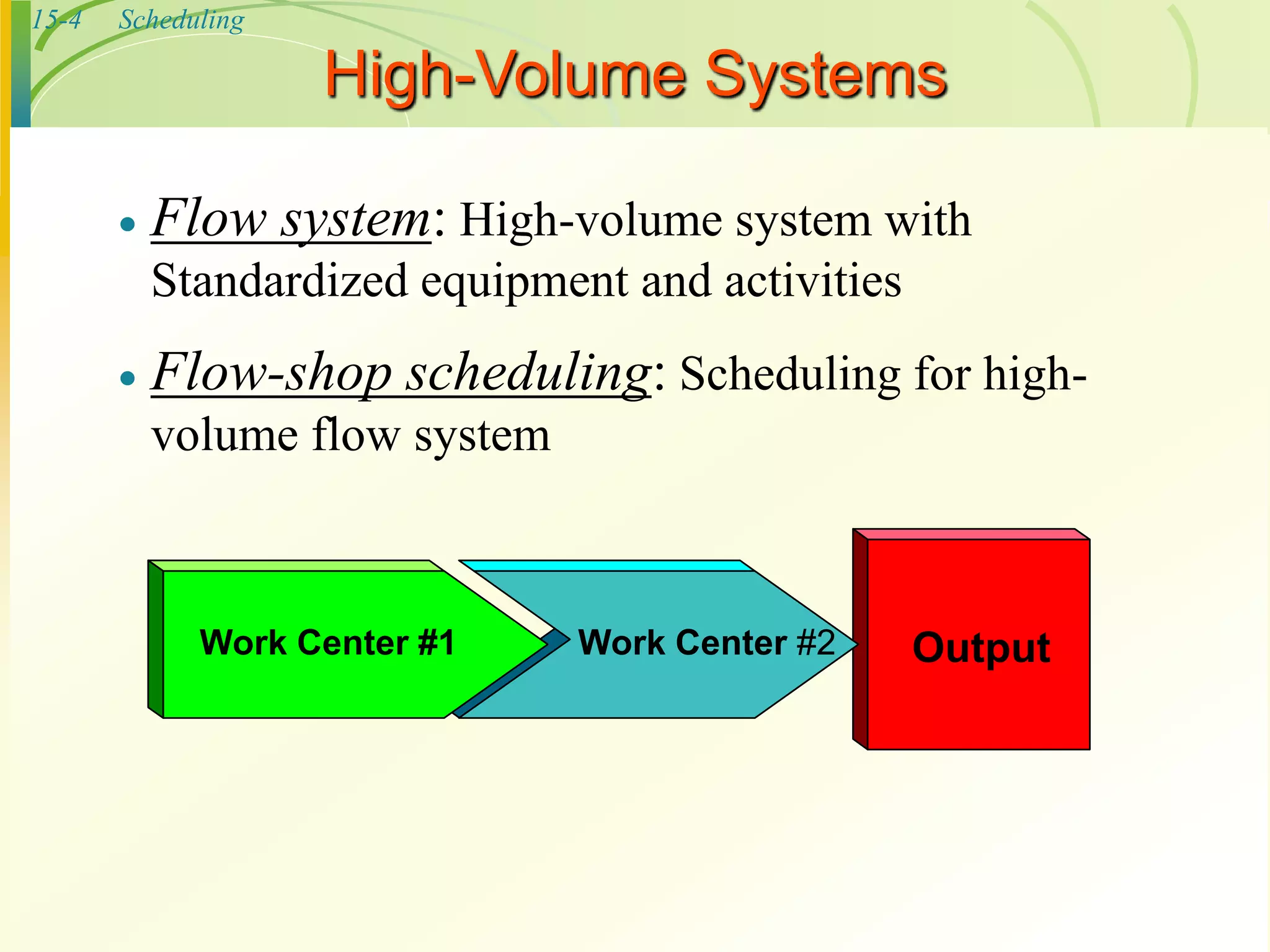

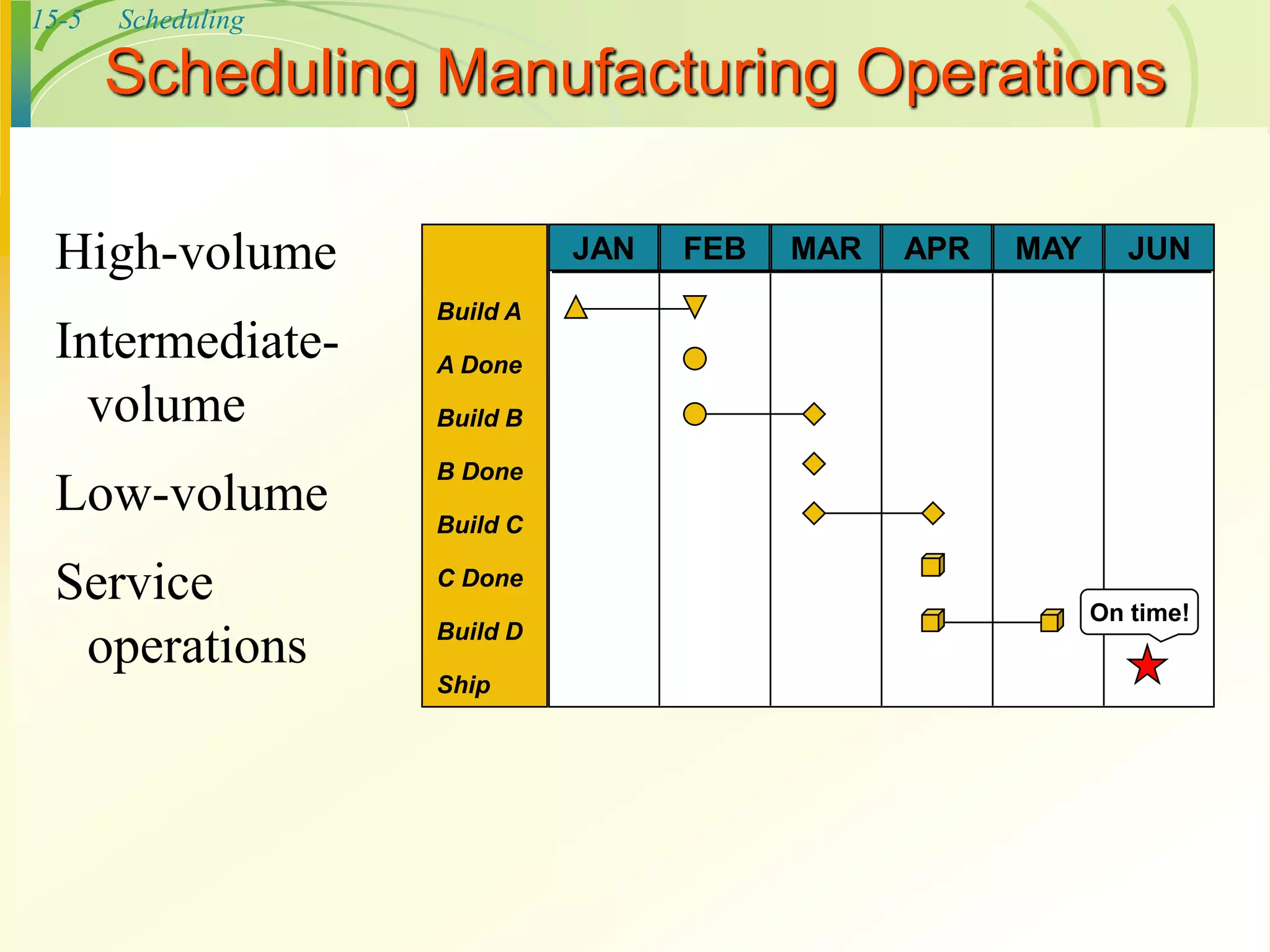

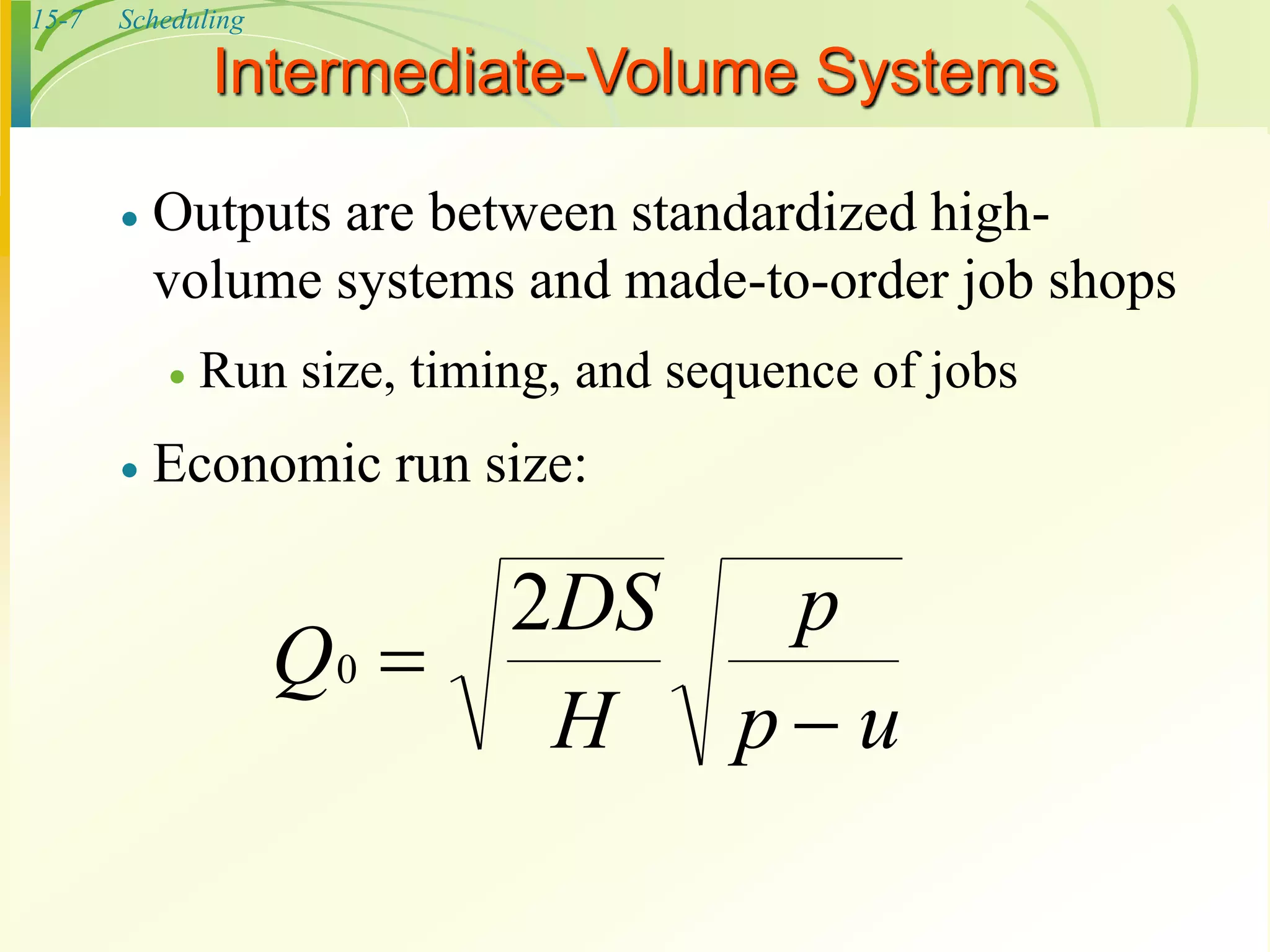

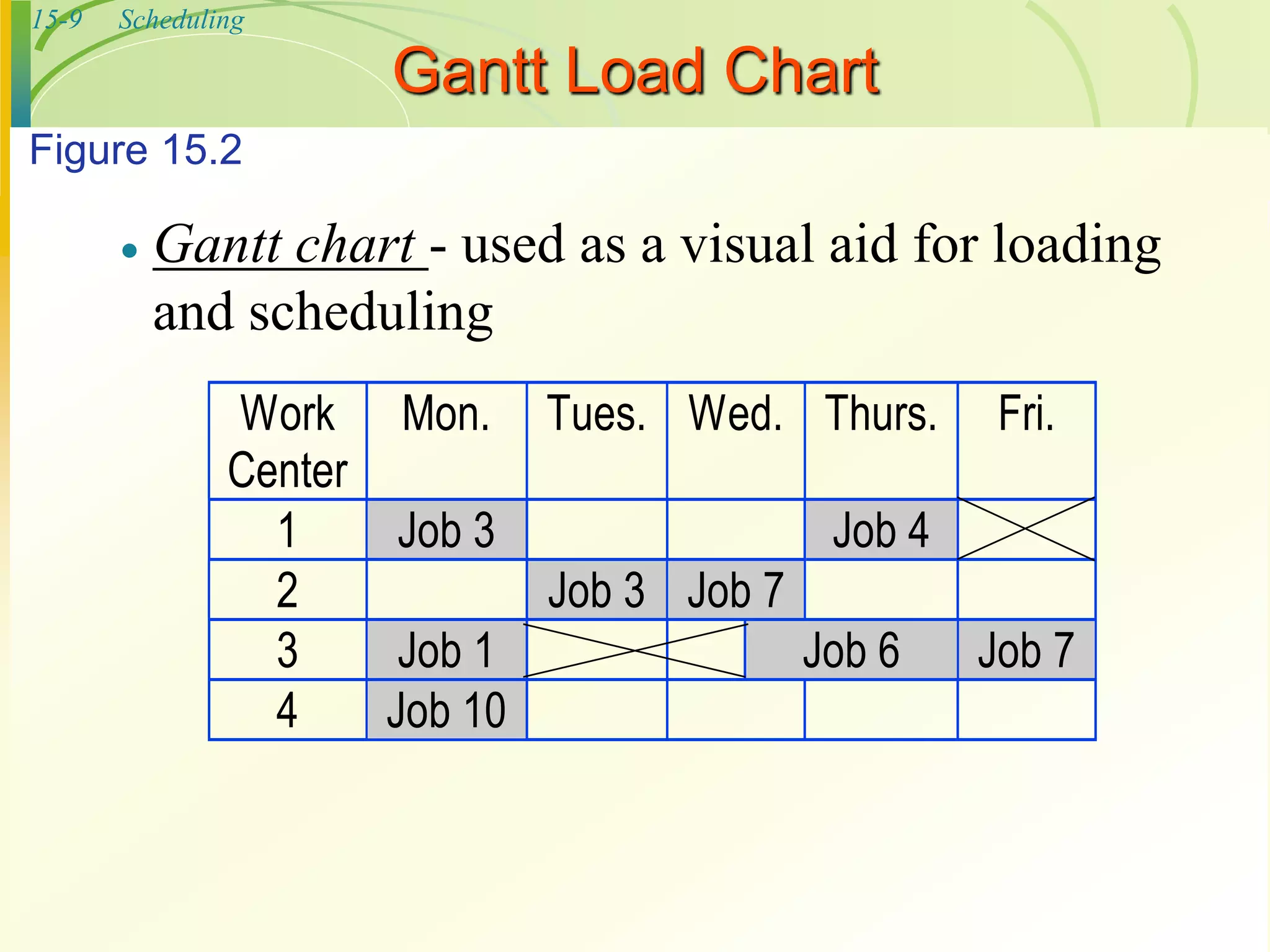

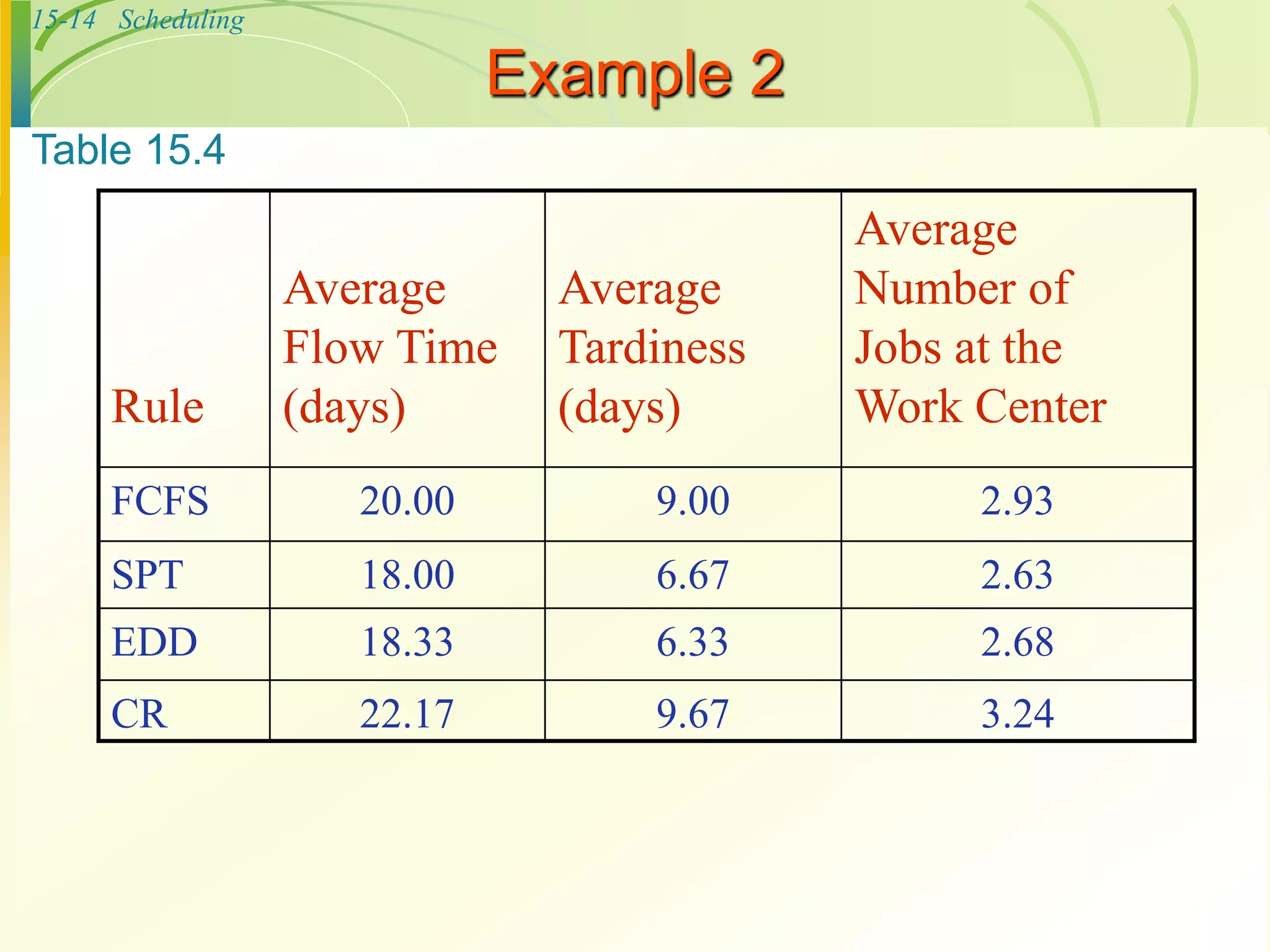

This document discusses scheduling in operations management. It begins by defining scheduling and describing its benefits, then examines different types of scheduling systems for high, intermediate, and low volume production. It discusses tools for scheduling like Gantt charts and different loading and sequencing rules. The document also covers scheduling challenges, minimizing difficulties, and scheduling for service operations and cyclical industries. It provides an overview of key concepts in production and service scheduling.