5 s concept

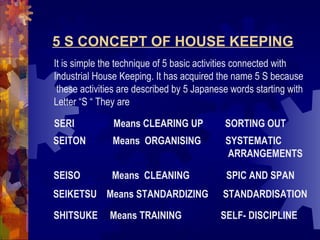

- 1. 5 S CONCEPT OF HOUSE KEEPING It is simple the technique of 5 basic activities connected with Industrial House Keeping. It has acquired the name 5 S because these activities are described by 5 Japanese words starting with Letter “S “ They are SERI Means CLEARING UP SORTING OUT SEITON Means ORGANISING SYSTEMATIC ARRANGEMENTS SEISO Means CLEANING SPIC AND SPAN SEIKETSU Means STANDARDIZING STANDARDISATION SHITSUKE Means TRAINING SELF- DISCIPLINE

- 2. NEED FOR 5 ’S PRACTICE The need for implementing 5’S activities in any industry is listed Below : • To create a pleasant work place • To reduce equipment break down time & to increase operation time • To avoid possible investment in new machinery & equipment • To eliminate waste of time in searching & handling • To reduce defects identify the cause for poor quality and initiate corrective action • To reduce maintenance of cost of machines • To make effective use of space • To promote better team work and enhance safety • To create better visibility of activities performances & the results

- 3. WHERE AND WHEN DO WE START • Work places – Offices and Shop floors and it is a company wide There is no place exempted from 5’ S activities in any organization WHEN DO WE START : There is no need to wait for taking up good things for action. However, if we have a growing symptoms of this following status Then clearly the time has come for us to think of need for 5;S Activities: • Poor state of machines / equipments / tools leading to quality deterioration • More time is spent in direct and indirect areas by way of searching for tools / files / Documents • Poor house keeping leads to unsafe work place and indirect losses • Poor material discipline leading to manufacturing delays

- 4. STEP-1 SERI – SORTING OUT Defined as “ sort out unnecessary items and straighten up” To start with undertake major cleaning up activities involving the men In the respective work areas. At this point keep in mind the sprit of Waste elimination.Develop specific policy and guidelines on the Disposal of unwanted things and upkeep necessary items.Devise Storage method depending on the priority of the need of the items. SOME CHECK POINTS • Sort through,then sort out • Identify what you need and discard what is unnecessary • Differentiate clearly between necessary & unnecessary • Look at work in process • Eliminate unnecessary tools • Dispose un used machinery • Remove unwanted papers documents

- 5. STEP-2 –SEITION – ORGANISING SYATAMATIC ARRANGEMENT Defined as : “Place for every thing and every thing in place” This activity involves simple steps as suggested below : • Analyze the present condition • Fly storage places / methods • Devise proper layout / classification • Develop rules and procedure. SOME CHECK POINTS • Set all work related items in order • Assign separate location for essential items • Make spaces / shelves self explanatory so that every one knows what goes where. • Ensure things are ready to use when needed • Always keep every thing in its own place • Ensure things / tools etc are put away after use

- 6. STEP- 3 – SEISO – SPIC & SPAN Defined as : “After – work maintenance and clean up” Cleaning more than skin deep. It means that it is not enough if we Resort to superficial cleaning alone, but efforts must be taken to keep The work place and equipment spotlessly clean and shining so that Any abnormally or defects would be visible, thereby attracting immed Iate attention to set right such short comings.In other words it is an Action of beautifying the work place with a sense of purpose.These Activities include sweeping,wiping,inspecting,polishing,painting,and Maintaining sparkling cleanliness. Some Check Points: • Maintain equipment and tools • Keep the work area free of trash and dust • Check shop floor for cleanliness • Empty out cans at end of shift • Assign clean responsibilities for “Clean up” • Check all machines for cleanliness

- 7. STEP-4 – SHIKETSU-STANDARDIZING Defined as “prevention of problems by keeping things standardized And maintaining a good environment” This activity helps to maintain the work place on proper condition By setting standards using visual control.It also helps in identifying Malfunctioning areas so that corrective action on abnormality Could immediately be taken • The limit indicators with increased visibility like the jewelers box • Different tags/labels to indicate where/what/how much should be stored • Control check list to help people maintain the standards Some Check points: • Are the men wearing dangerous clothing • Is the roof leaking • Is the place for eating / smoking ear marked • Is the gang way clearly marked • Is there heavy noise, vibration,heat etc

- 8. STEP-5 – SHITSUKE- TRAINING & DISCIPLINE Defined as : Maintaining good habits and discipline Remember that successful implementation of 5’S activity requires Involvement and commitment of everyone in the organization. Therefore it is essential that proper care is taken and due attention is Paid to create awareness by effectively communicating the rules and Methods of 5’S activities. • Posters,banners,badges& booklets describing useful hints from time to time would certainly serve this purpose • Introducing 5’S calendar, daily check list, responsibility check list would help clarifying the status and pave way for improvement. • Setting goals and targets, holding conventions and competitions would motivate people achieve greater results in this area • Where ever difficulties are experienced,it is worth while to train the men in the area in order to sort out specific problems. • While developing standards and setting goals,it is essential that operating people are involved

- 9. Seri-Organization – Stratification Management & dealing with cause Types of Activities 1.Throw away things that are not needed 2.Organize cleaning of shop floor 3.Organize storage of parts and files 4.Policy of one is the Best ONE SET OF TOOLS / FILES ONE DAY PROCESSING ONE STOP SERVICE FOR CUSTOMER ONE LOCATION FILE Location Action

- 10. SEITON - NEATNESS “Functional storage and eliminating the need to look for things” Typical Activities Every things has a clearly designated name and place 30 Seconds retrieval and storage Filing standard and control Eliminating covers and locks First in first out arrangement Neat notice boards Functional placements of materials Straight line and right angle layout Location Action By

- 11. SEISO- CLEANING Cleaning as Inspection and degree of cleanliness Activity Individual Cleaning responsibility assigned Make cleaning and inspection easier Regular cleaning campaign Cleaning inspection and correct minor mistakes Even clean the places most people do not notice. Location Action

- 12. SHIKETSU - STANDARDIZING Visual management and 5’S Standardization Activity Transparency (e.g. Glass covers for see through Inspection “OK” marks or label Fire extinguishers and Exit Boards Directional marking on pipes and gangways Colour coded pipes Responsibility labels Location Action By

- 13. SHITSUKE- TRAINING AND DISCIPLINE “Habit formation and disciplined work place” Activity All together cleaning Do daily physical exercise all together Practice pick up component and rubbish Wearing helmets goggles hand gloves etc Practice dealing with emergencies Seeing is believing – Check for 5’S environment Location Action By

- 14. SOME EXAMPLE 5S Before 5S After 5S

- 15. EXAPMLE

- 16. GOOD BAD UGLY

- 17. THE GOOD

- 18. SUMMARY 5-S is for you. Clean-up and organize your work area every day so that each new day is easier and safer than the day before Share your input with your leaders so that the tools you need will be available to you, increasing your efficiency. Volunteer to help with the 5S tours and 5S events. Take a good look around...Imagine zero waste/zero confusion!