5S Basic.ppt

- 1. GABRIEL

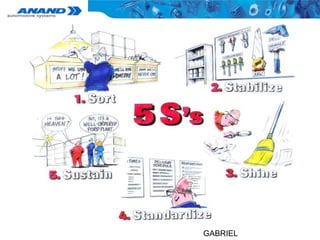

- 2. What is 5S ? 5S is a simple but highly effective set of techniques 5S methodology was developed in Japan 5S is the foundation for any continuous improvement 5S removes waste from work environment through better workplace organization, standardization, visual communication and general cleanliness 5S factories are so well organized that abnormal situations will be readily apparent

- 3. Why 5S ? A better Quality of life Clean Shop floor and Office Gain Space and can detect problems more easily No special effort for visits and audits of Customer, Supplier and Top Management Easy to locate tools, documents, parts leading to Higher Efficiency Easy to reduce MUDA(Waste)

- 4. GABRIEL What Are The 5S’s ? 5S’s Japanese English Meaning 1 S SEIRI SORT Remove unwanted items 2 S SEITON SET A place for everything and everything in its place 3 S SEISO SHINE Cleaning with meaning 4 S SEIKETSU STANDARDISE Establish Standards for first 3Ss 5 S SHITSUKE SUSTAIN Sustain & improve the first 4Ss The 5S-method is a five principals program for safety, cleanliness and order at your own workstation. The 5 S are: It can be realized in production as well as in office areas.

- 5. GABRIEL SERI - (SORTING) Meaning Distinguish between necessary and unnecessary items and eliminate the unnecessary items Activity • Establish a criteria for eliminating unwanted items. • Eliminate unwanted items either by disposing or by relocating. Success Indicator Area saved or percentage of space available What is unnecessary • Item is not needed • Item is needed however quantity in stock is more than what is needed for consumption in near future Do not hesitate to throw away what is not useful!

- 6. GABRIEL Identifying unnecessary • Things fallen back / behind the machine or rolled under it • Broken items inside the machine • Stock of Rejected items •Small quantity of material no longer in use • Broken fixture, tools, bits, etc, may be lying •Material brought for some trial, still lying even after trial • Old fixtures, tools not in use, damaged equipment parts, etc. • Shelves and lockers tends to collect things that nobody ever uses, like surplus, broken items etc. • Dust, material not required seem to gather in corners • Posters,bulletins on wall, damaged or unwanted files, papers, stickers • Remains of torn notices, cello tape pieces • Unwanted table, rack, trolleys, bins, etc.

- 7. GABRIEL BEFORE AFTER Location : All areas Kaizen Theme : Work place improvement Old reports & document boxes available in all the areas All the boxes moved to the record room No boxes available at shop floor

- 8. GABRIEL BEFORE AFTER Location :Main Cell Kaizen Theme : To eliminate dumping of material Rack eliminated Unwanted things lying in the rack

- 9. GABRIEL SEITON - (SYSTEMATIC ARRANGEMENT) Meaning • To determine type of storage and layout that will ensure easy accessibility for everyone. Activity • Plan storage of items based on its use, function & frequency • Creating place for everything and keep everything in its place Success Indicator • Time saved in searching • Time saved in material handling How to achieve Systematic Arrangement? • Label each item and fix location to prevent searching • Prevent mistakes with coding by shapes & color • Follow first in first out rule • Put the things back to their location after their use

- 10. GABRIEL • Color code wires, ducts, pipes, fixtures, trolleys, oil, etc. • Store blades, dies, other important consumables in the protected place • Maintain blades, dies regularly by applying rust preventive, oiling etc. • Designate a place for each component / part • Decide on how much quantity to be stored • Fix location for Registers or any other frequently used documents • Safety aspects – fire prevention, pollution, leak, spillage • Put the tools or fixtures in the order you need them • Identify location for tables, stands, trolleys, bins, etc. • Label Instruments & Measuring Devices • Show direction of flow What To Do?

- 11. GABRIEL Define how to order the objects Do not place heavy objects high up. Easy to pick up, easy to put back, easy to do. Place the most used objects at a height between the shoulder and the elbow Make shelves appropriate to the size and weight that will be placed there. Correct Incorrect

- 12. GABRIEL Define how to order the objects Equipment on wheels: define the position by color and write the name of the vehicle. As a general rule, indicate the position of everything that has to be moved, so as to be able to replace it more easily. Mark the position of the objects (marks, labels, ......)

- 13. GABRIEL Draw very legible marks in the installations to make inspection easier. Do not leave containers directly on the floor use a platform: the parts will not be soiled, and corrosion and knocks can be avoided. Parts Box Platform

- 14. GABRIEL Avoid placing things too far back as it makes them difficult to reach. Access difficult Access easy

- 15. GABRIEL Plan strategies to make organisation easy Marking Makes it Possible to Replace Documents Exactly in Order Badly placed Well placed

- 16. GABRIEL Plan a system for easy positioning

- 17. GABRIEL This functional order must be organised with the help of the operators, who can make proposals to the 5S work group. This will ensure: • Greater safety • Improved quality of parts made • No time wasting Plan a clear system for positioning giving maximum information in a minimum of time Indicate the part names Heightlimit Indicayte the quantity and the name of the container On the platform Area line Mark the area according to the size of the containers

- 18. GABRIEL BEFORE AFTER Location : O/T Leak Testing m/c Kaizen Theme : Proper Arrangements Provide stand to keep the fixture & identified No place to keep fixture, so kept on floor

- 19. GABRIEL BEFORE AFTER Location : FF Final Assy. Kaizen Theme : Proper Arrangement Place has been fixed & identified No proper place to keep the poly bag, Axle hole checking pin & upper cap

- 20. GABRIEL BEFORE AFTER Location : FF FINAL ASSY. Kaizen Theme: Easy To Identify No Proper Arrangement for IPIR And Scrap Register Now Proper Arrangement Of IPIR By Keeping Separator.

- 21. GABRIEL BEFORE AFTER Location : O/T Quality Station Kaizen Theme : Proper Place Proper place provided & identified No proper place to keep the master pieces, due to this master pieces getting damage

- 22. GABRIEL BEFORE AFTER Location : O/T Quality Station Kaizen Theme : To Avoid Damages Plug Gauges & Snap gauges kept properly & identified Plug Gauges & Snap Gauges kept without any arrangement

- 23. GABRIEL BEFORE AFTER Location : O/T Leak Testing m/c Kaizen Theme : For Easy Identification Model wise board displayed No identification for painted outer tubes as per model

- 24. GABRIEL BEFORE AFTER Location : Main Cell ( Material trolley Area) Kaizen Theme : Work place Improvement Material trolleys are not getting parked properly ,Walls getting Damaged and difficult to access Guide ways to the trolley wheels provided to keep the trolleys only in the guide ways and stoppers given to avoid damages forming on the walls also Stopper

- 25. GABRIEL BEFORE AFTER Location : Manual MIG welding Kaizen Theme : Proper place and identification No proper place to display SOP and defect samples Proper place provided, colored and identified the defect samples

- 26. GABRIEL CONTINUAL IMPROVEMENT BEFORE AFTER Location : Training Hall Kaizen Theme : For Easy Identification Identified line wise in lights & in switches Before no identification for lights

- 27. GABRIEL BEFORE AFTER Location : TSG Kaizen Theme : Proper Arrangement All the sheet s displayed in folders & properly arranged A4 sheet fixed with one pin & no proper arrangement

- 28. GABRIEL BEFORE AFTER Location : Display Corner Kaizen Theme : Office TPM Different types of board pins used Board pins standardized

- 29. GABRIEL VISUAL STANDARDS REQUIREMENT 1. A4 / A3 sheets are to be fixed with 4 pins only. 2. A4 sheet separator to be fixed with 2 pins at the ends. 3. All displays are to be in straight line both horizontally & vertically. 4. Do not display any sheets on top of the existing display. 5. Do not display damaged / oil soaked / folded sheets. 6. Use one standard pin type in complete board.

- 30. GABRIEL

- 31. GABRIEL SEISO - (SHINE) SEISO is keeping the workplace clean and also inspecting while cleaning Meaning Activity •Spend at least 5 Minutes daily for cleaning •Use appropriate tools for cleaning •While Cleaning also inspect for damage,defects and potential problems •Clean the Hidden areas also •Cleaning without care can cause more damage •Inculcate the mindset “It is My Duty to Clean My Place” Success Indicator • Equipment Life is Improved •Future problems are proactively identified and corrected

- 32. GABRIEL This involves finding solutions of improvement for places difficult to clean (for this use sheets indicating difficulty of access filled in during the intial cleaning). In a place of difficult access, dust, residues and dirt accumulate. Superficial cleaning is not sufficient. Difficult places also have to be cleaned, but above all, propose ideas that will make cleaning simpler. Identify places difficult to clean and correct the situation

- 33. GABRIEL This involves, after identifying the sources of dirt during the optimization phase, resolving the problem and as far as possible eliminating the dirt. The only way to succeed in having a lasting state of cleanliness is not to clean all the time, but to avoid soiling in the first place. Seek the causes of dirt and correct the situation

- 34. GABRIEL Places difficult to reach, if they are not changed, are a source of discouragement for individuals and go back to being dirty again. Continue to complete the sheets with indications (anomalies, dirt, difficult access, observations). After repeated cleaning, the difficulties become clear and note must be taken of them. Propose solutions for improvement to the work group who will make a combined report. The work group will use the good ideas, will ensure that the work decided on is done quickly, will comment on the work refused and see that the improvement sheets are displayed Identify places difficult to clean and correct the situation I ’m fed up with this!

- 35. GABRIEL This involves the efficient cleaning of the installations and the environment, understanding the necessity for this task Carry out all the cleaning in company with the members of the team and the 5S work group taking account of the safety instructions. Indicate the places with a problem with a label indicating the nature of the problem. 3s - Spic and Span (Clean) the installations Water leak Oil Leak Missing part Broken cap Displacement Deformation Deterioration Missing nut Twisted part Lost cap Etc.

- 36. GABRIEL Spic and Span - Cleaning equipment Rag Brush Bleach Sweeping brush Vacuum cleaner Paint Paint brush Other equipment

- 37. GABRIEL BEFORE AFTER Location : FF FINAL ASSY. APS Theme : To Avoid Dust Trolley & Bins are changed now dust and oil will not stay Dust & Oil stays at bins and trolley

- 38. GABRIEL BEFORE AFTER Location : TT Outer Tube Cleaning m/c Kaizen Theme : Eliminate Cleaning Oil from components spilling on to the floor Tray provided to prevent oil spill

- 39. GABRIEL BEFORE AFTER Location : O/T Cell (BTA) Kaizen Theme : To Avoid Handling Leakage All stand changed in inside While keeping in draining stand oil spilling at floor

- 40. GABRIEL BEFORE AFTER Location : Cell 3 BTA M/c Kaizen Theme : To Avoid Leakages Concentricity gauge provided inside the machine Coolant oil getting leak from outer tube while checking Concentricity

- 41. GABRIEL BEFORE AFTER Location : Cell (9 & 8) – VMC M/c Kaizen Theme: Easy Flow of Chips Now provided wide channel, now chips flow easily Chips struck in m/c channel due to this coolant getting overflow

- 42. GABRIEL BEFORE AFTER Location : O/T cell Kaizen Theme: Easy to Clean Provided fiber sheet inside the m/c.easy to clean Chips were flashing on the m/c window,difficult to clean

- 43. GABRIEL SEIKETSU- STANDARDISE “Define the standards that will enable the workstation to remain free of unnecessary items, orderly, spotless and inspected while specifying how to eliminate the causes of dirt, grime, leak and clutter.” Meaning Activity • Establish uniform standards and procedures for labeling, color codes, indicators and safety norms • Display visual signage and control wherever possible • Establish proper Checklists, Responsibility Lists and Schedules Success Indicator • Increases Quality & Productivity • Safe & Ease Working Conditions • Mistakes are Eliminated • Ownership and sense of pride among employees

- 44. GABRIEL Seiketsu Following of earlier 3S Standardized work procedures, Maintaining safe & hygienic conditions in work place contributing to a serene atmosphere. Steps to Seiketsu Develop standards/ Evaluation criteria with workmen (Sop's housekeeping standards) Establish checking procedure Establish feedback procedures

- 45. GABRIEL 2‘S STANDARD CIT OIL BARREL STORING AREA. Max - 3 Min - 1 Always Keep barrel In vertical condition. Always ensure barrel Top should be sealed. KEEP THE AREA CLEAN AND NEAT AS PER THE DISPLAY DO NOT KEEP ANY EXCESS OIL BARRELS OR OTHER THINGS RESPONSIBILITY: LOADING PERSON & STORES SHIFT INCHARGE.

- 46. GABRIEL Standard

- 47. GABRIEL SHITSUKE- SUSTAIN “Management should encourage co-workers to keep up the good habits acquired by supporting them and helping them to comply with and improve on the standards” Meaning Activity • Provide continuous guidance and training • Conduct regular 5S audits , display the result • Analyze audit findings & act • Create Interest & Involvement thro’ publicity & competitions • Ensure everyone is committed to “5S is my Responsibility” • SHITSUKE is perhaps the toughest of the 5S’s Success Indicator 5S Becomes Habit

- 48. GABRIEL Gains and benefits for company and employees The advantage of the 5S method is to continuously implement and maintain order and cleanliness in the plant in a structured way. The methodology is based on teamwork and can be applied to all areas. The activity 5S consists of 5 principals and offers numerous advantages for the company as well as for the employees. The basic advantage for the plant is to arrange the spaces clear. Consequently we achieve an organized and structured operation which will increase productivity.

- 49. GABRIEL The method allows the employees to work in a clean environment and to feel well at their workstations. In addition it offers the employee the possibility to feel more connected with his/her work by i.e. submitting proposals for improvement which will be implemented as soon as possible. The major advantages are: Sensitization of the employees for safety, order and cleanliness at their workstations Take over more responsibility Basis for standardization (i. e. labeling, implementation shadow board monitoring) and continuous improvement Increased transparency of the process The 5S-method is a good way to involve every people in a same plant project.

- 50. GABRIEL S .N Description 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 1 No Trolleys/Boxes in front of the Display Boards 2 Arrangements of Files & Registers in File Rack 3 Display Boards are in identified Location 4 No Uneeded Equipments/Trolleys/Boxes near Common Display Area 5 Uneeded Equipments/Trolleys/Boxes in Front of Fire Extinguisher Marking 6 No Filter Paper overflow from the Collection Box 7 No Oil Spillage near Filter Paper Collecting Box 8 No Chips on the floor near Chip Collecting Trolleys 9 Cleanliness of Chips Trolley 10 No Trolleys parked outside the identified location 11 No Machined Outer Tubes are in Blue Trolley 12 All the MachineTrolleys & Bottom Tray should free from Chips & Burr 13 Chips collecting trolley parked in correct position 14 No Supplier Bins are used for collecting spillage 15 Tool Rack I & 2 located in identified location 16 Tools & Fixtures in Rack - 1 & 2 are located in identified location 17 All available Tool in Rack 1 & 2 ready for use 18 No Parts/Tools laying on Concentricity Checking gauge station 19 No Chips on Gauges(Ring Gauge/Plug Gauge/Concentricity Gauge etc ) 20 All Parts/Tools laying in identified locations on the machines 21 Is Drain Locators are in Good Condition 22 All gauges & Registers(Bottom Rack) stored in identified location in Quality Station 1(Near Cell 3& 4) 23 All gauges & Registers(Bottom Rack) stored in identified location in Quality Station 2 & Rack (Opposite to Cell 5) 24 Is JH happened on JH Time & Updated Check sheet available 25 Kettles kept in identified location & Cleaned 26 Oil Drum Trolley parked in Identified Location 27 Files & Registers arranged properly in SOP station 28 Machine Gaurds in its position 29 Rejection Trolley parked in identified location 30 Rejection Trolley Boxes free from Chips 31 Is Daily Rejection Disposed 32 All the Machine Gaurds(Achralic sheet) in Good Condition 33 No Chips & Oil on Shop Floor Rating Criteria : 30/ 33 - G, 27/ 33 - Y, < 27/ 33 - R Zone Leader to Audit Daily Auditor to audit on every S aturday P/managers/TPS/5S/O/T Cell checksheet Common Points Near Machine Rating S ignature O/T CELL 5S DAILY MONITORING SHEET GABRIEL, H Zone leader : DILIP REDDY Auditor : MURALIDHAR BHAT Year :2009 Zone : FF Area :O/ T Cell Month :

- 51. GABRIEL THANK U