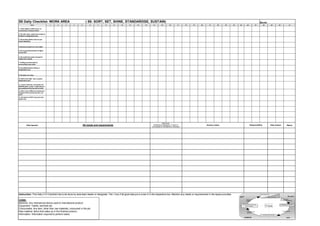

This document is a daily 5S checklist for a work area. It contains 31 items to check to ensure the work area is properly organized, clean, and safe. Key things to check include that tables are clean, waste is emptied and in designated spots, tools and unused equipment are turned off and stored properly, aisles are clear, and bins and materials are in specified locations. The checklist also notes to turn off electric connections at the end of shifts and return empty bins to the warehouse pickup point.