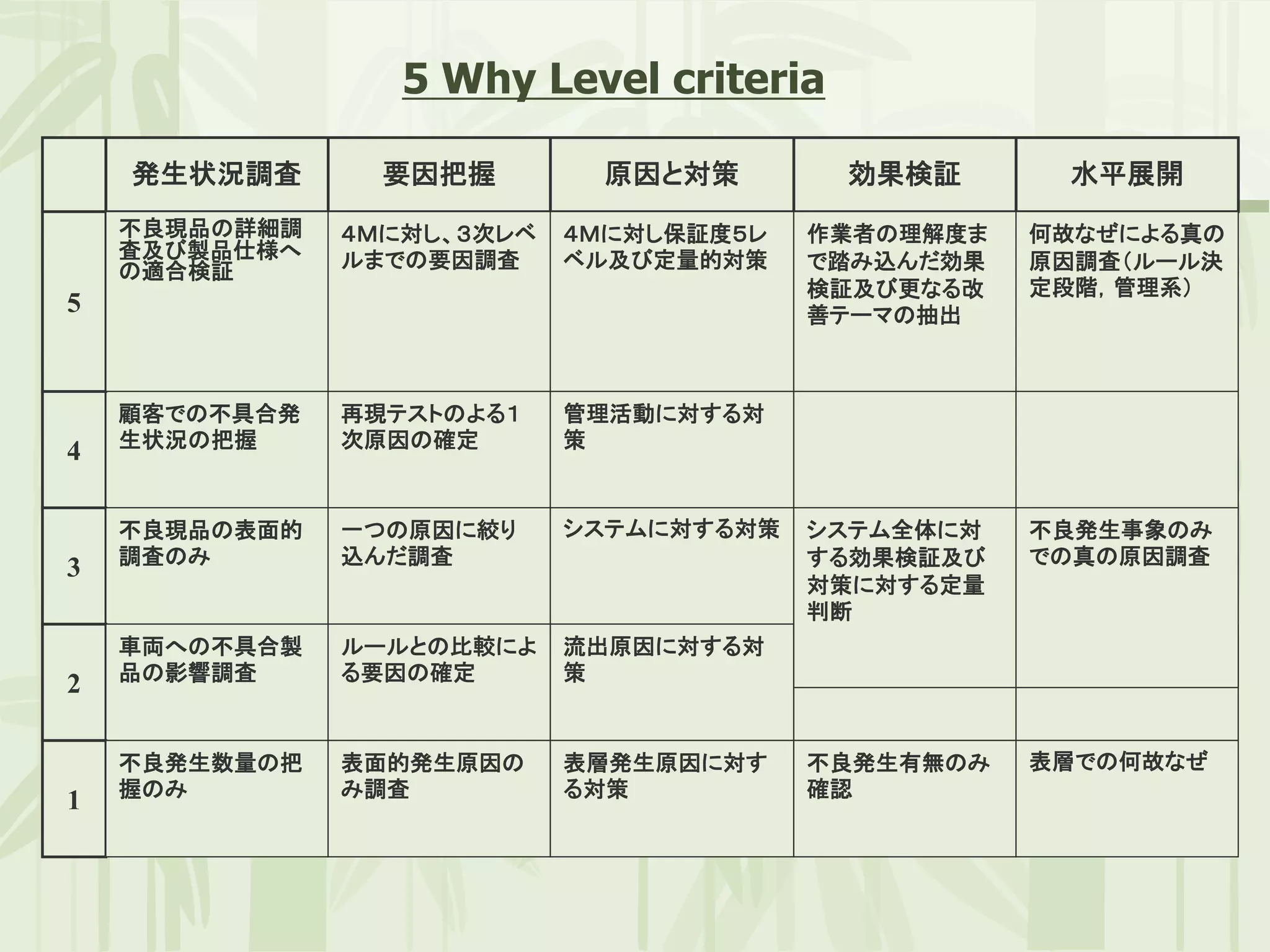

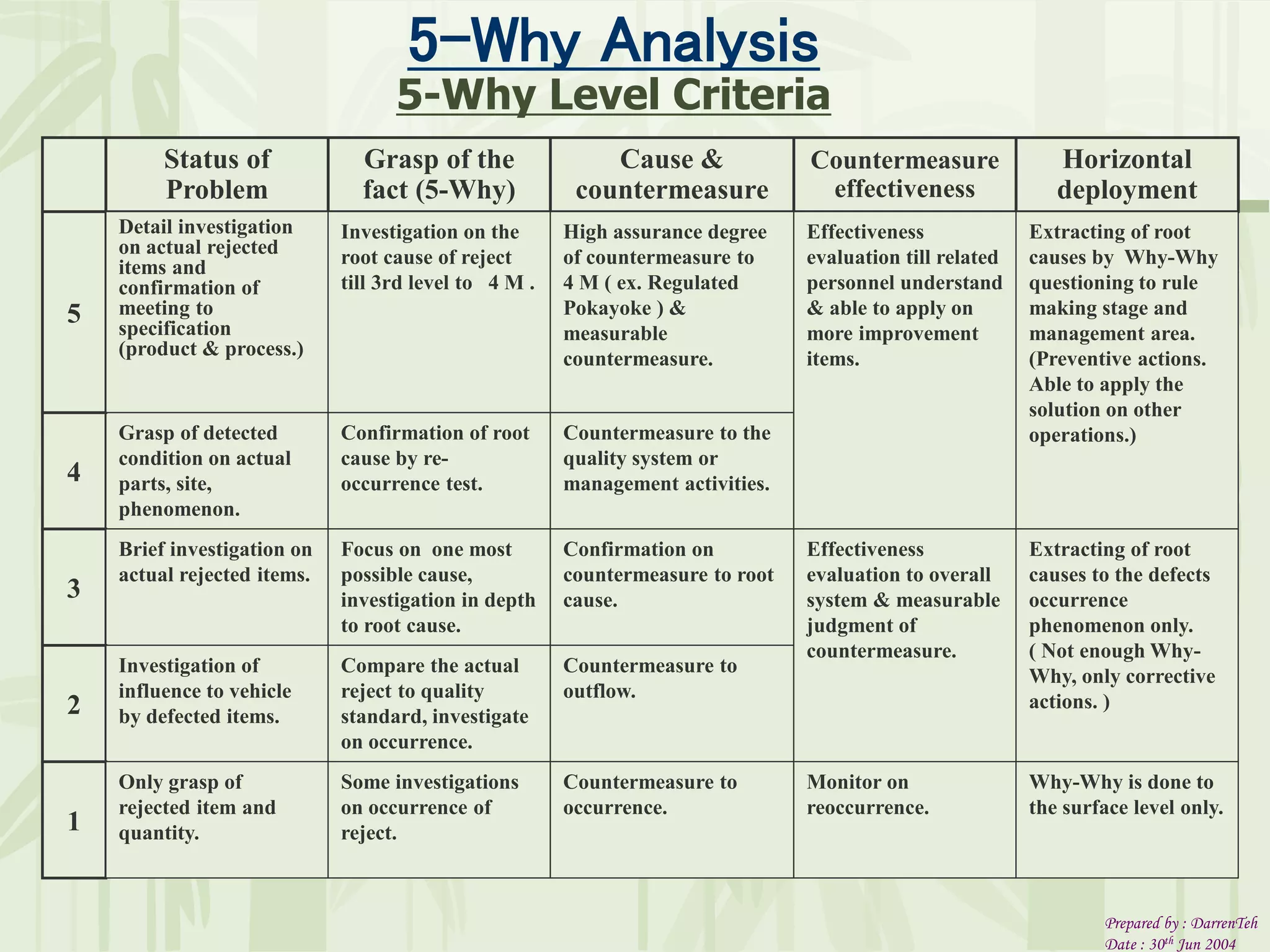

This document outlines levels of problem analysis and countermeasure implementation. Level 1 involves monitoring problem occurrence but not fully investigating causes. Higher levels involve more thorough root cause analysis using techniques like 5-Why, confirmation testing, and countermeasures applied more broadly. Level 5 represents the deepest analysis of root causes, most robust countermeasures, and effectiveness evaluation applied across the entire system. The document provides criteria for evaluating the thoroughness of a 5-Why analysis report.