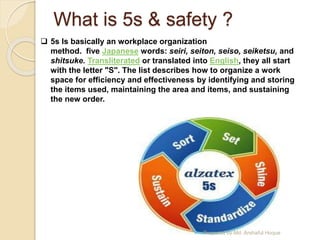

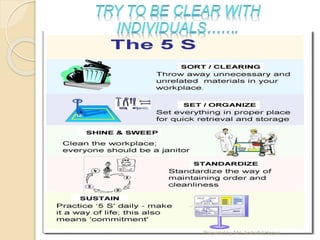

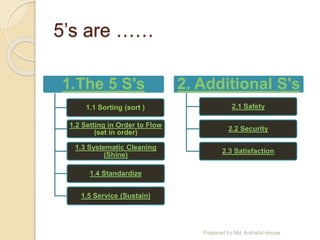

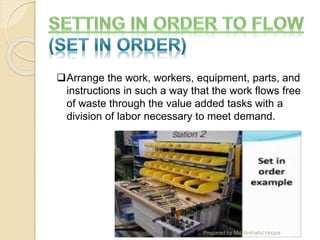

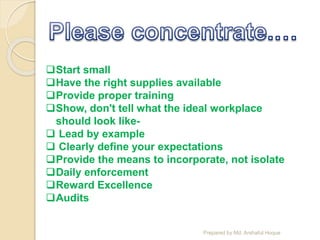

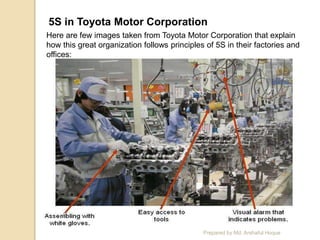

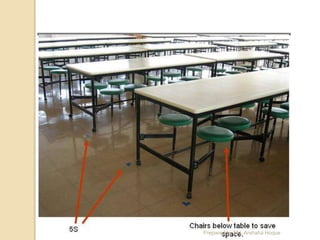

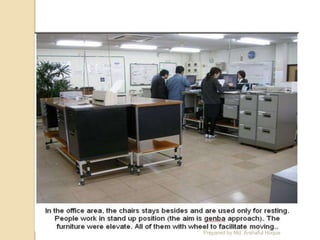

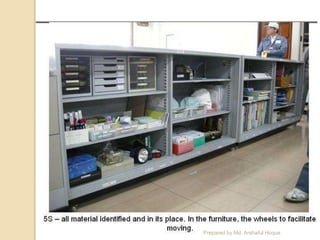

The document discusses 5S and safety. It defines 5S as a workplace organization method involving five Japanese words that start with S: sort, set in order, shine, standardize, and sustain. The document outlines the key aspects of each S and provides additional S's of safety, security, and satisfaction. It then gives top ten suggestions for 5S success such as starting small, training, and rewarding excellence. The document discusses applying 5S and safety in modern workplaces and provides examples of 5S implementation at Toyota Motor Corporation.