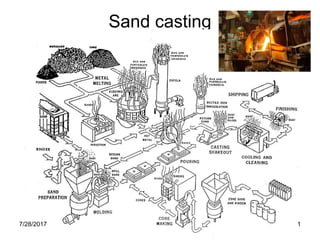

This document discusses the process of sand casting, including:

- The typical steps of sand casting which include creating a pattern, compacting sand in a flask around the pattern, adding gates/runners/risers, and pouring molten metal.

- Key process parameters like pouring temperature and cooling rate that influence the final cast structure and properties.

- Challenges like shrinkage and ways to address it through part design like using risers and making the parting line straight.

- Considerations for part design to enable successful sand casting like geometric simplicity, generous fillets, uniform thickness, and draft angles.