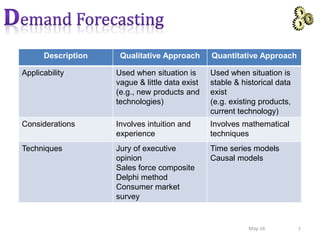

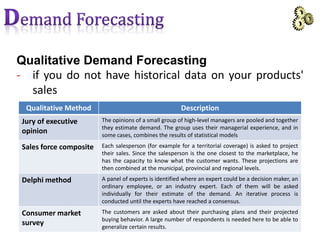

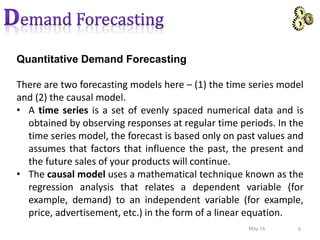

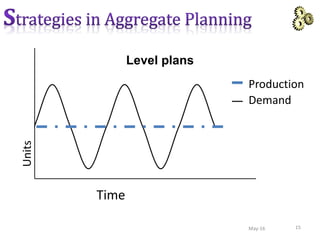

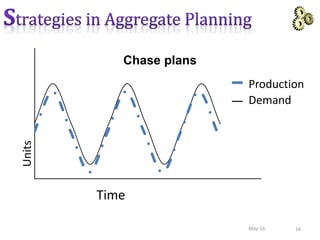

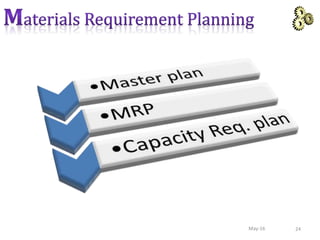

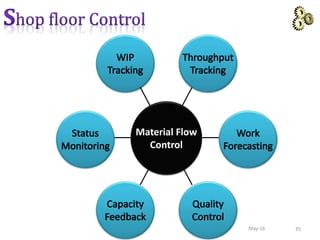

This document discusses various aspects of production planning and control, including demand forecasting, aggregate production planning, scheduling, workforce planning, materials requirement planning, capacity planning, production control using just-in-time, and shop-floor control. It addresses decisions around acquiring, utilizing, and allocating limited production resources to meet objectives while considering constraints. The main goal is to make appropriate production decisions around workforce levels, lot sizes, overtime, and sequencing.