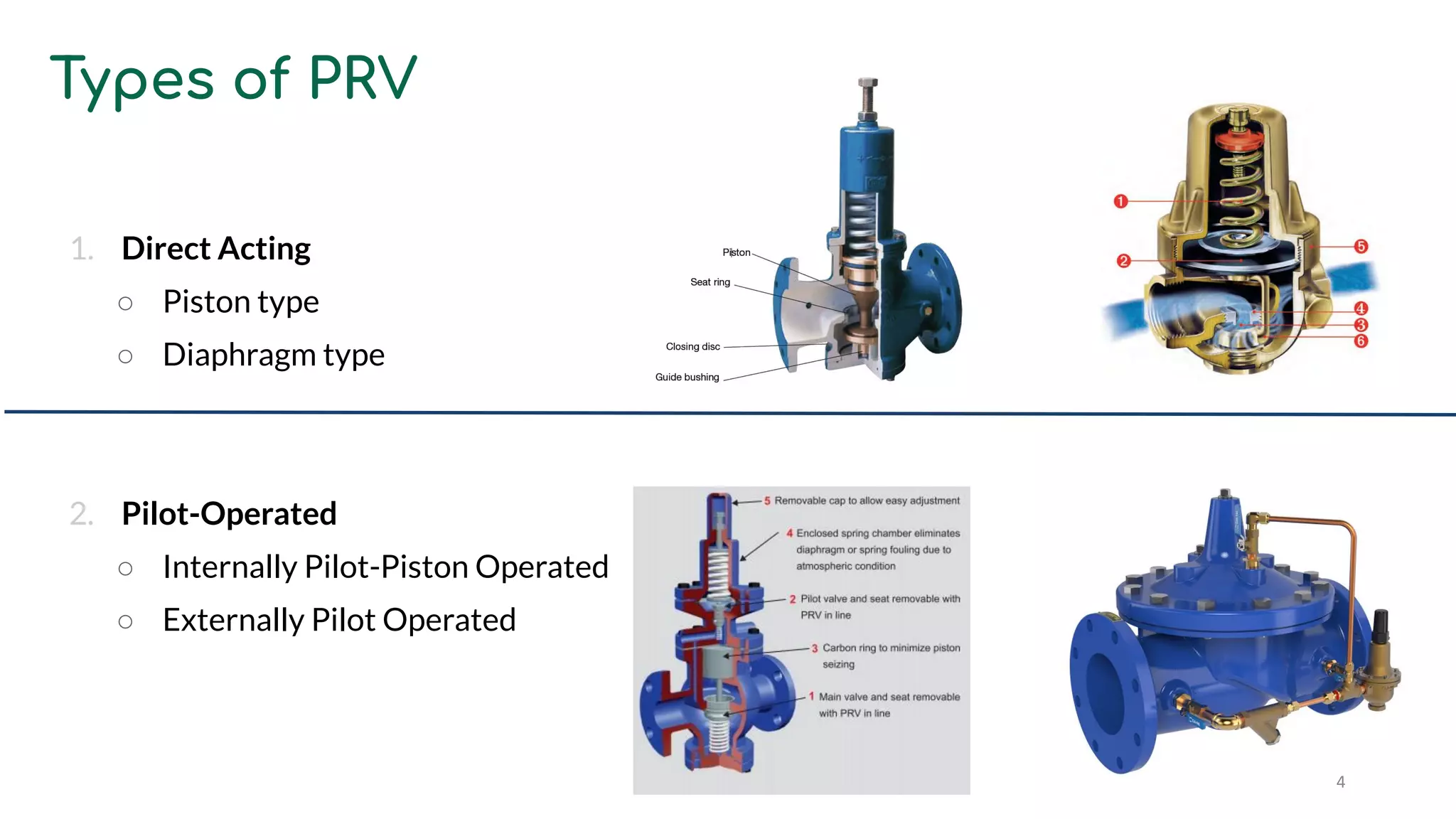

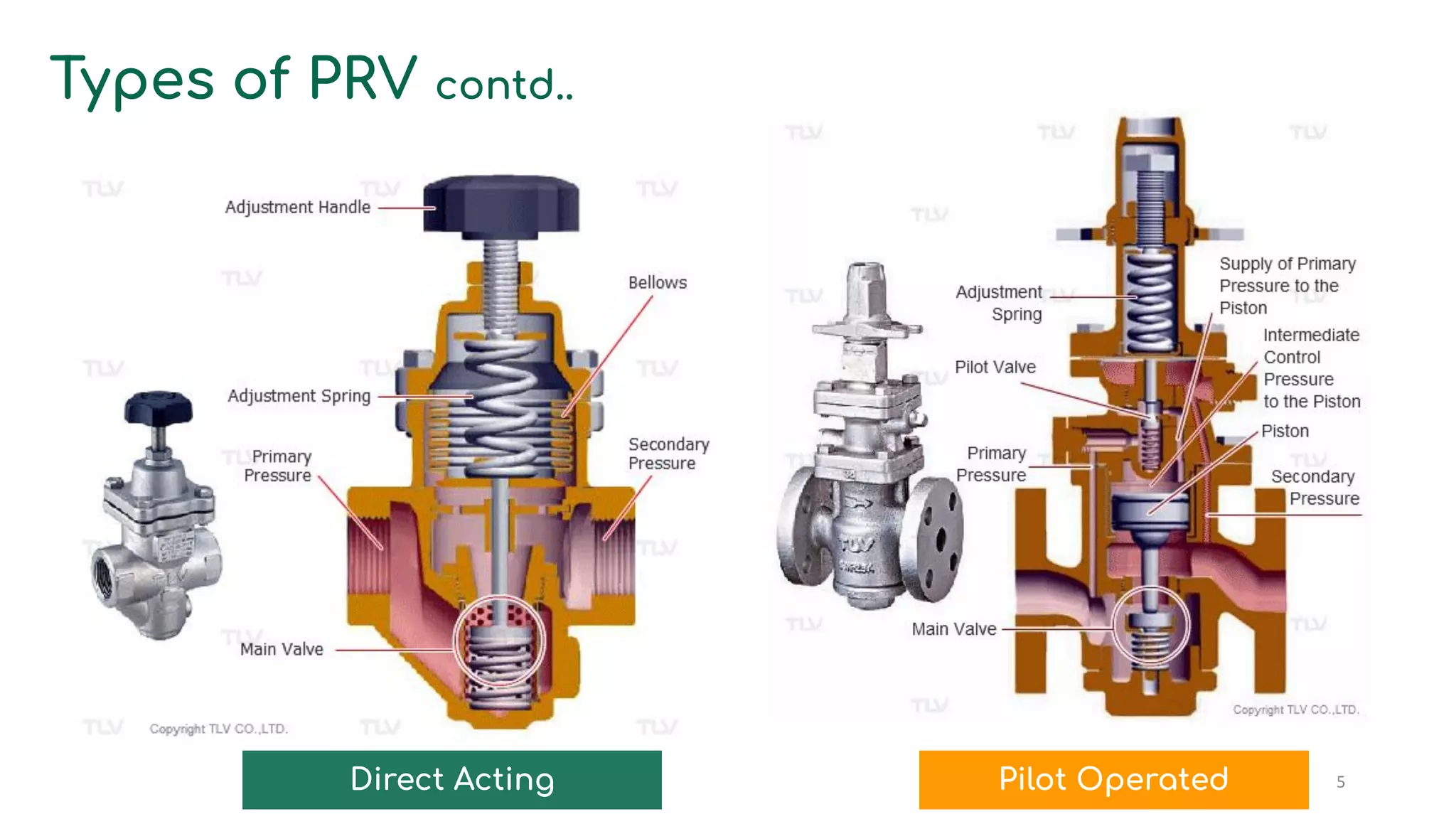

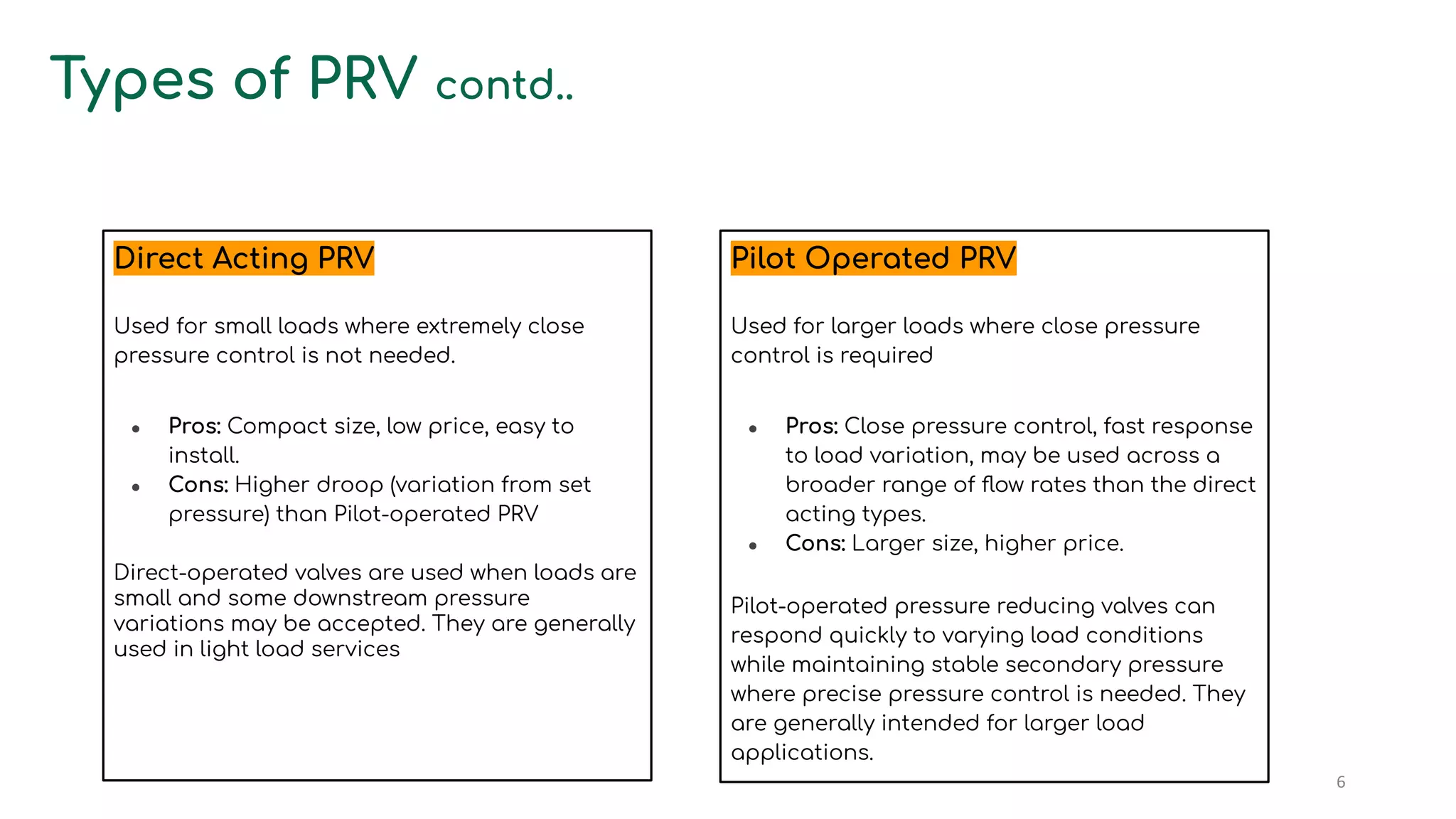

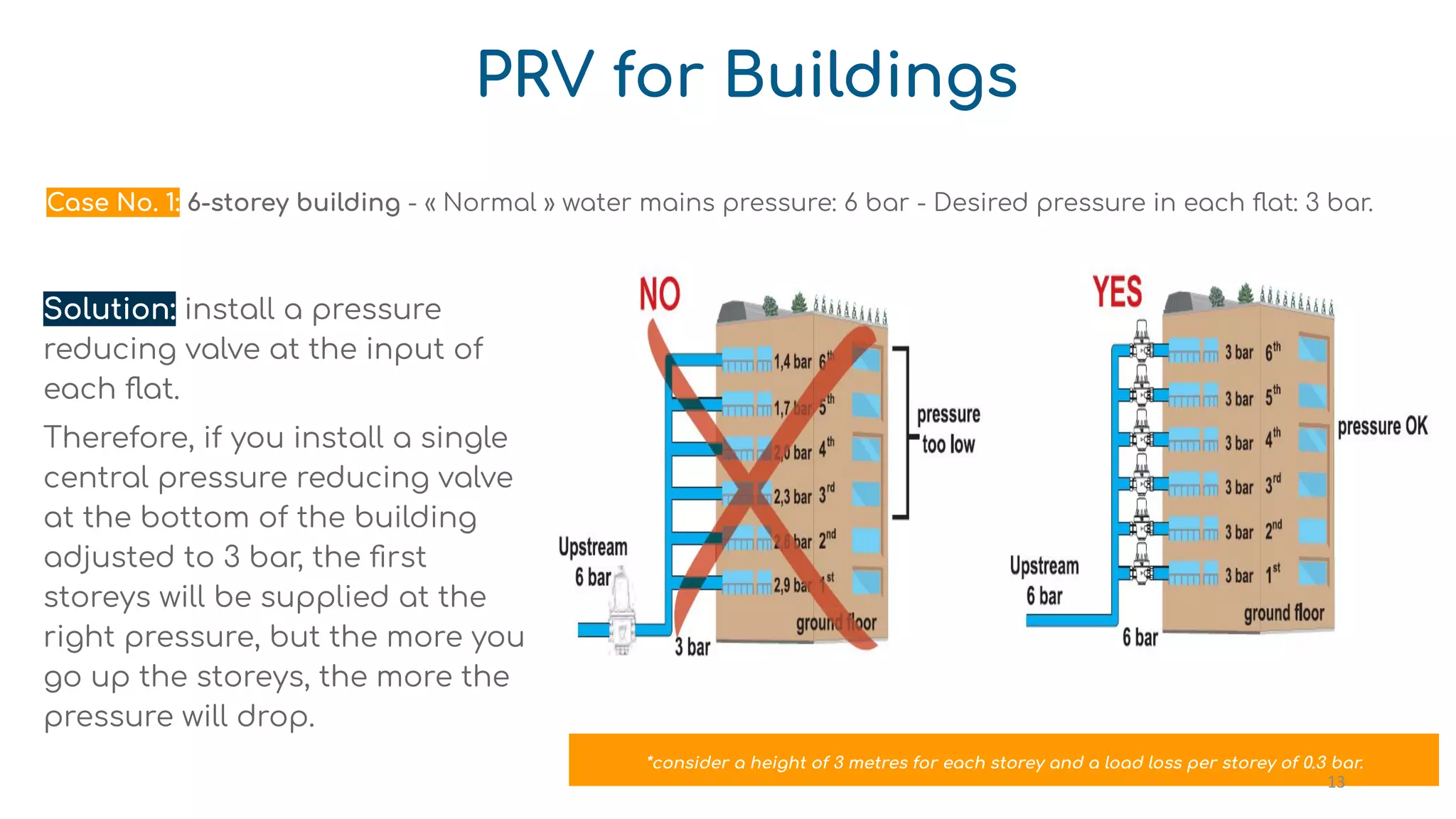

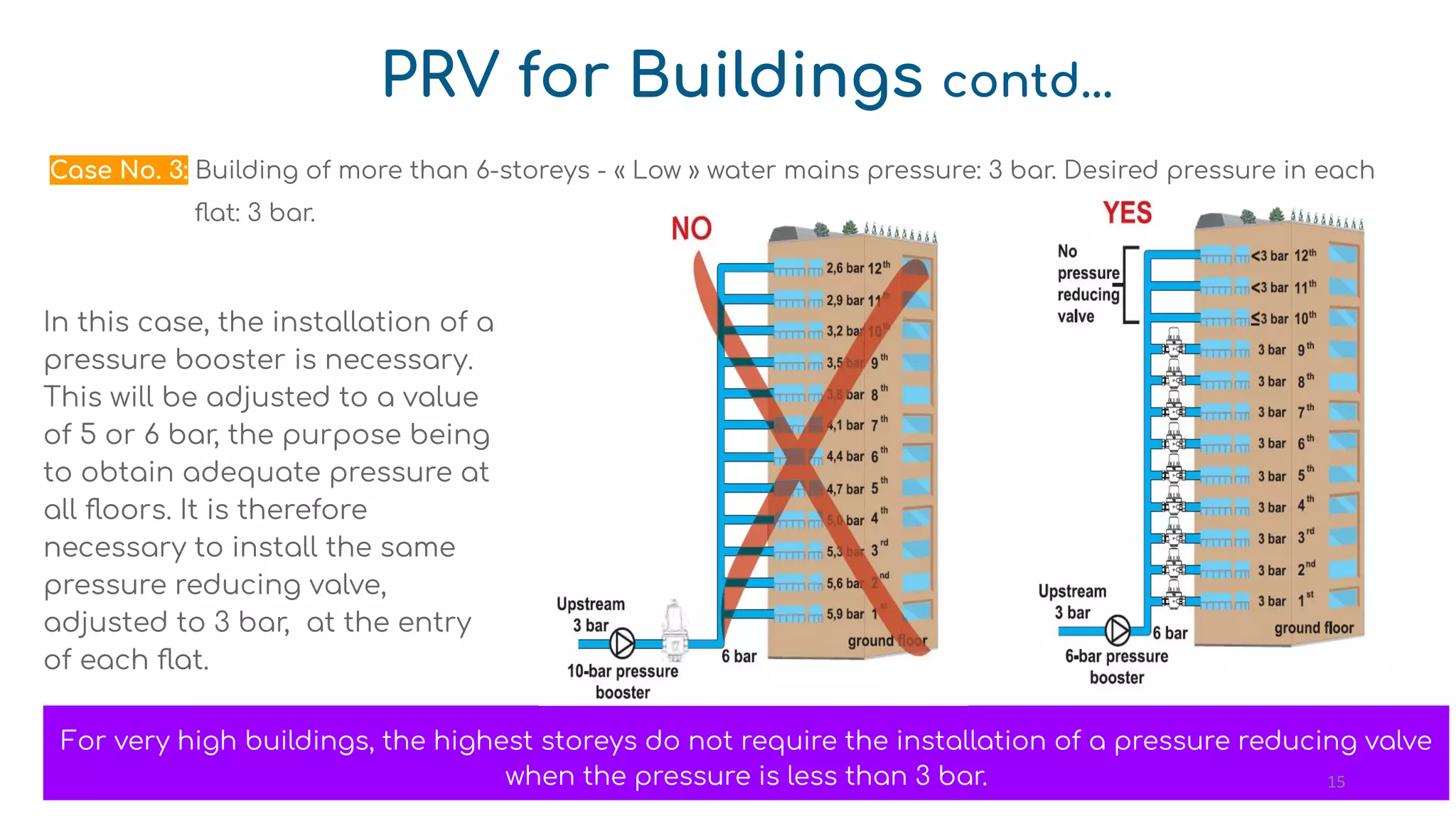

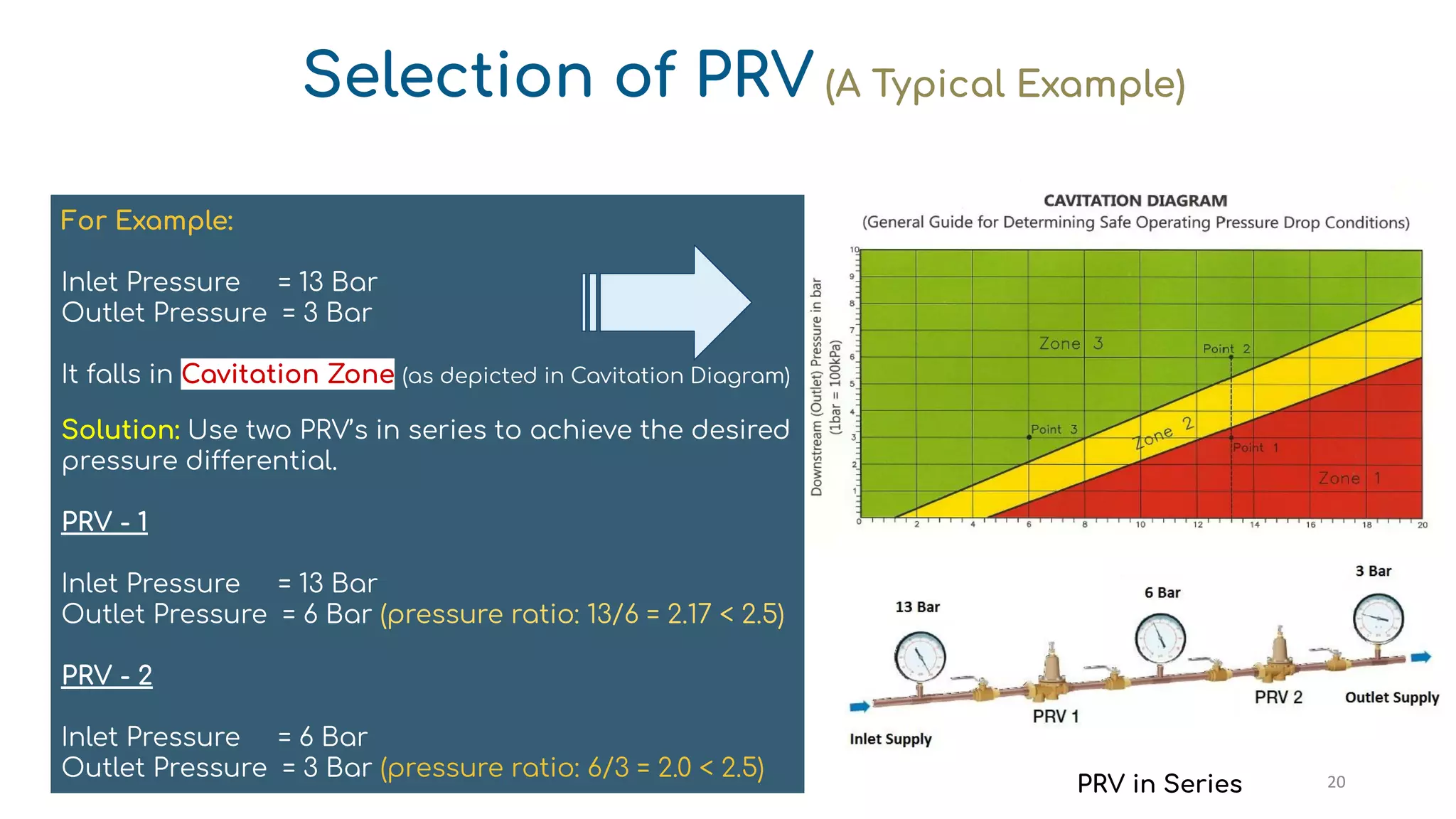

The document covers the functions, types, and benefits of pressure reducing valves (PRVs), which maintain desired water pressure and reduce wastage, noise, and water hammering in pipelines. It explains the working principle, installation recommendations, and troubleshooting techniques, emphasizing the importance of avoiding cavitation by maintaining a pressure ratio below 2.5. Different applications, such as residential buildings and high-storey installations, are discussed, highlighting the need for proper sizing and series or parallel configurations.